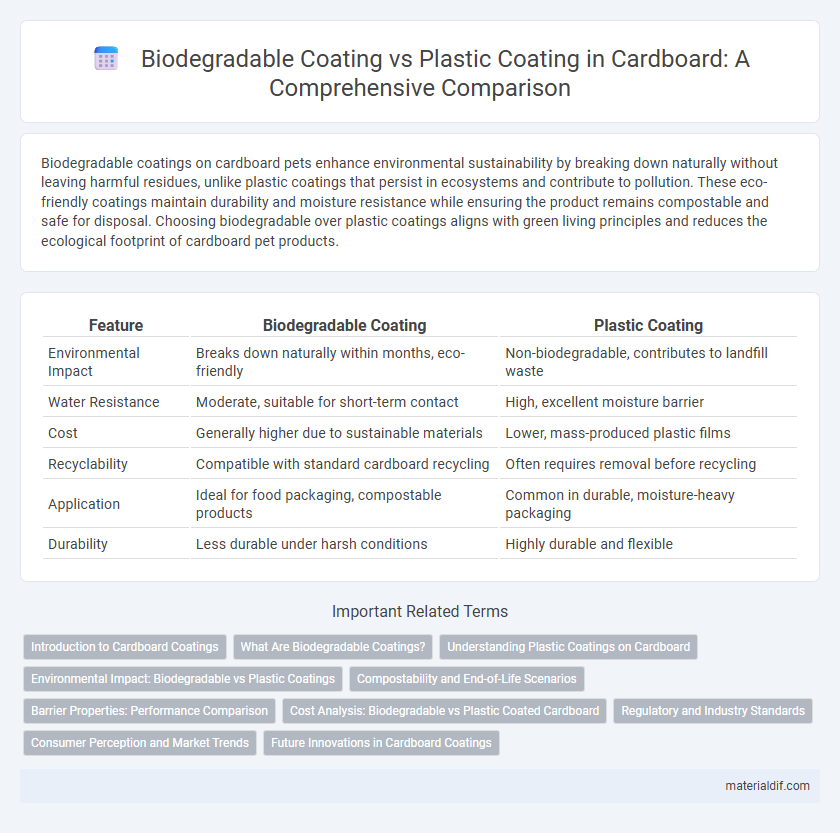

Biodegradable coatings on cardboard pets enhance environmental sustainability by breaking down naturally without leaving harmful residues, unlike plastic coatings that persist in ecosystems and contribute to pollution. These eco-friendly coatings maintain durability and moisture resistance while ensuring the product remains compostable and safe for disposal. Choosing biodegradable over plastic coatings aligns with green living principles and reduces the ecological footprint of cardboard pet products.

Table of Comparison

| Feature | Biodegradable Coating | Plastic Coating |

|---|---|---|

| Environmental Impact | Breaks down naturally within months, eco-friendly | Non-biodegradable, contributes to landfill waste |

| Water Resistance | Moderate, suitable for short-term contact | High, excellent moisture barrier |

| Cost | Generally higher due to sustainable materials | Lower, mass-produced plastic films |

| Recyclability | Compatible with standard cardboard recycling | Often requires removal before recycling |

| Application | Ideal for food packaging, compostable products | Common in durable, moisture-heavy packaging |

| Durability | Less durable under harsh conditions | Highly durable and flexible |

Introduction to Cardboard Coatings

Cardboard coatings enhance durability by providing moisture resistance and improved structural integrity. Biodegradable coatings, made from natural materials like cellulose or starch, offer eco-friendly alternatives by breaking down naturally without harming the environment. Plastic coatings, typically polyethylene-based, provide superior water resistance but pose challenges in recycling and contribute to long-term pollution.

What Are Biodegradable Coatings?

Biodegradable coatings are eco-friendly layers applied to cardboard that break down naturally through microbial activity, enhancing compostability and reducing environmental impact. Unlike plastic coatings, which are petroleum-based and persist in the environment, biodegradable coatings use renewable materials like starch, polylactic acid (PLA), or cellulose derivatives to maintain water resistance and durability. These coatings support sustainable packaging by allowing cardboard to decompose more rapidly in industrial composting facilities while maintaining protective qualities.

Understanding Plastic Coatings on Cardboard

Plastic coatings on cardboard create a moisture-resistant barrier that enhances durability and protects against spills, making them ideal for food packaging and shipping applications. These coatings typically consist of polyethylene or polypropylene, which, while effective, significantly reduce the cardboard's recyclability and increase environmental impact due to their non-biodegradable nature. Understanding the trade-offs between durability and sustainability is crucial for businesses aiming to optimize packaging performance while minimizing ecological footprints.

Environmental Impact: Biodegradable vs Plastic Coatings

Biodegradable coatings on cardboard significantly reduce environmental impact by breaking down naturally in soil, minimizing landfill waste and pollution compared to plastic coatings that persist for decades, contributing to microplastic contamination. Plastic-coated cardboard often hinders recycling processes, leading to increased waste and carbon emissions, while biodegradable alternatives enhance compostability and circular economy efforts. Choosing biodegradable coatings supports sustainable packaging solutions by lowering ecological footprints and promoting resource regeneration.

Compostability and End-of-Life Scenarios

Biodegradable coatings on cardboard enhance compostability, allowing the material to break down naturally within industrial or home composting systems, reducing landfill waste significantly. Plastic coatings, typically polyethylene-based, hinder biodegradation and complicate recycling processes due to their resistance to microbial activity and separation challenges. Choosing biodegradable coatings aligns with sustainable end-of-life scenarios by promoting circular economy principles and minimizing environmental impact through effective composting pathways.

Barrier Properties: Performance Comparison

Biodegradable coatings on cardboard provide effective moisture and grease resistance while maintaining eco-friendly disposal benefits, though they may exhibit lower durability compared to traditional plastic coatings. Plastic coatings typically offer superior barrier properties against water vapor and oxygen, enhancing product shelf life and preventing contamination in packaging applications. Advances in biodegradable materials are narrowing the performance gap by improving barrier efficiency and mechanical strength, promoting sustainable packaging solutions.

Cost Analysis: Biodegradable vs Plastic Coated Cardboard

Biodegradable coating on cardboard typically incurs higher initial material costs than traditional plastic coatings due to specialized raw materials and production processes. However, long-term savings arise from reduced environmental disposal fees and potential compliance benefits with emerging regulations on single-use plastics. Evaluating total cost of ownership reveals that biodegradable coatings present a more sustainable and economically viable solution for businesses aiming to minimize ecological impact while managing expenses.

Regulatory and Industry Standards

Biodegradable coatings on cardboard comply with increasing global regulatory demands for sustainable packaging, including standards like ASTM D6400 and EN 13432 that certify compostability and environmental safety. Plastic coatings, often derived from polyethylene, face stricter scrutiny due to their non-biodegradable nature and evolving regulations such as the EU Single-Use Plastics Directive aimed at reducing plastic waste. Industry standards emphasize the shift toward biodegradable coatings to meet extended producer responsibility (EPR) requirements and align with consumers' growing demand for eco-friendly packaging solutions.

Consumer Perception and Market Trends

Biodegradable coatings on cardboard are increasingly favored by consumers seeking sustainable packaging options, driving a significant shift in market demand away from plastic-coated alternatives. Market trends indicate a growing preference for eco-friendly materials, with biodegradable coatings enhancing brand image and aligning with regulatory pressures on reducing plastic waste. Consumer perception highlights environmental responsibility as a key factor influencing purchase decisions, propelling innovation and adoption in the cardboard packaging industry.

Future Innovations in Cardboard Coatings

Future innovations in cardboard coatings emphasize biodegradable materials derived from plant-based polymers like polylactic acid (PLA) and chitosan, offering enhanced compostability and reduced environmental impact compared to traditional plastic coatings. Advanced bio-coatings improve water resistance, durability, and printability without compromising recyclability, addressing growing demand for sustainable packaging solutions. Emerging nanotechnology and enzyme-based coatings also promise to revolutionize cardboard performance by enabling smart functionalities such as antimicrobial protection and controlled biodegradation.

Biodegradable coating vs Plastic coating Infographic

materialdif.com

materialdif.com