Flexographic printing excels on cardboard due to its high-speed production and ability to print on uneven surfaces, making it ideal for packaging with complex shapes. Lithographic printing offers superior image quality and fine detail but is better suited for flat, smooth cardboard surfaces where color precision is critical. Choosing between flexographic and lithographic printing depends on the cardboard's texture and the desired print resolution for packaging needs.

Table of Comparison

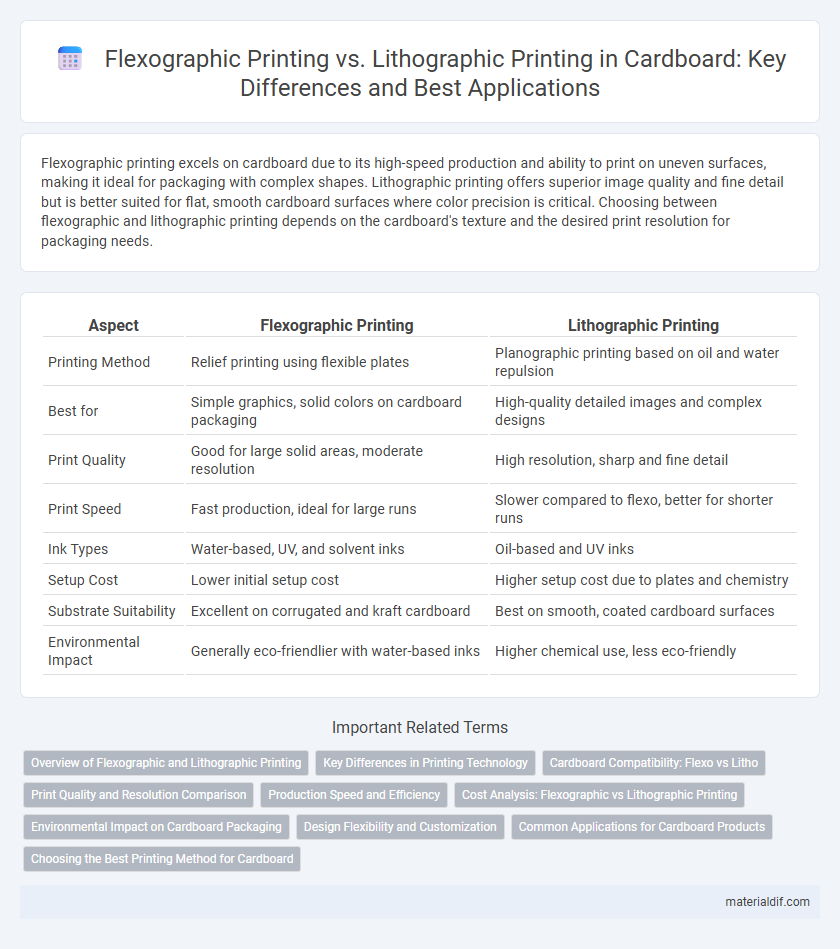

| Aspect | Flexographic Printing | Lithographic Printing |

|---|---|---|

| Printing Method | Relief printing using flexible plates | Planographic printing based on oil and water repulsion |

| Best for | Simple graphics, solid colors on cardboard packaging | High-quality detailed images and complex designs |

| Print Quality | Good for large solid areas, moderate resolution | High resolution, sharp and fine detail |

| Print Speed | Fast production, ideal for large runs | Slower compared to flexo, better for shorter runs |

| Ink Types | Water-based, UV, and solvent inks | Oil-based and UV inks |

| Setup Cost | Lower initial setup cost | Higher setup cost due to plates and chemistry |

| Substrate Suitability | Excellent on corrugated and kraft cardboard | Best on smooth, coated cardboard surfaces |

| Environmental Impact | Generally eco-friendlier with water-based inks | Higher chemical use, less eco-friendly |

Overview of Flexographic and Lithographic Printing

Flexographic printing utilizes flexible relief plates and fast-drying inks, making it ideal for high-speed printing on varied surfaces such as cardboard packaging. Lithographic printing employs flat plates with a chemical repulsion of oil and water, delivering high-resolution images and fine details primarily on smooth substrates. Both methods play crucial roles in cardboard production, with flexography favored for large runs and lithography chosen for superior image quality.

Key Differences in Printing Technology

Flexographic printing on cardboard uses flexible relief plates and fast-drying liquid inks, making it ideal for high-speed production and packaging materials with uneven surfaces. Lithographic printing, or offset printing, employs flat plates with water-repellent ink to produce high-resolution images and superior color accuracy on smooth cardboard surfaces. Key differences include flexography's adaptability to various substrates and faster turnaround, while lithography excels in image quality and fine detail reproduction.

Cardboard Compatibility: Flexo vs Litho

Flexographic printing excels in cardboard compatibility due to its ability to print on rough and uneven surfaces, making it ideal for corrugated cartons and packaging with textured finishes. Lithographic printing, while offering high image quality, requires smoother cardboard surfaces such as coated or paperboard substrates to achieve optimal results. For large-scale cardboard production with variable surface textures, flexography provides greater versatility and durability.

Print Quality and Resolution Comparison

Flexographic printing on cardboard offers moderate resolution typically ranging from 70 to 150 DPI, producing vibrant but less detailed images suitable for large runs and flexible packaging. Lithographic printing achieves higher resolution, often exceeding 300 DPI, delivering superior print quality with finer details and sharper color gradients, ideal for premium cardboard packaging. The choice between these methods depends on the required print clarity, detail precision, and production volume for the cardboard product.

Production Speed and Efficiency

Flexographic printing offers faster production speeds on cardboard due to its quick-drying inks and streamlined setup process, making it ideal for high-volume runs. Lithographic printing provides superior image quality but typically operates at slower speeds, which can reduce overall efficiency in large-scale cardboard production. Choosing flexography often results in lower downtime and higher throughput, enhancing cost-effectiveness for packaging manufacturers.

Cost Analysis: Flexographic vs Lithographic Printing

Flexographic printing on cardboard generally offers lower setup costs and faster turnaround times compared to lithographic printing, making it more cost-effective for large print runs or packaging requiring variable data. Lithographic printing, while having higher initial plate and setup expenses, delivers superior color accuracy and image quality, which can justify the investment for premium or small-batch cardboard products. The choice between flexographic and lithographic printing depends heavily on the print volume, quality requirements, and budget constraints of the cardboard project.

Environmental Impact on Cardboard Packaging

Flexographic printing on cardboard packaging uses water-based inks that emit fewer volatile organic compounds (VOCs), making it a more environmentally friendly option compared to lithographic printing, which often relies on solvent-based inks with higher VOC emissions. Flexography's efficient ink usage and quicker drying times reduce energy consumption, lowering the overall carbon footprint of cardboard production. While lithographic printing offers high image quality, its environmental impact is increased by the need for chemical processing and waste generation, making flexographic printing preferable for sustainable cardboard packaging.

Design Flexibility and Customization

Flexographic printing offers superior design flexibility and customization for cardboard packaging through its ability to print on a variety of substrates and adapt easily to different ink types and colors. Lithographic printing provides high-resolution, detailed images but is less adaptable for short runs or frequent design changes, making it less ideal for customized, variable packaging designs. The choice between these methods depends on production volume and the need for intricate artwork versus versatile and rapid design adjustments.

Common Applications for Cardboard Products

Flexographic printing is widely used for cardboard packaging such as corrugated boxes, food containers, and shipping cartons due to its ability to print on uneven surfaces with quick drying times. Lithographic printing is preferred for high-quality packaging like retail folding cartons and point-of-purchase displays where detailed images and vibrant colors are required. Both techniques cater to different market needs, with flexography excelling in large-volume, cost-effective runs and lithography offering superior print resolution for premium cardboard products.

Choosing the Best Printing Method for Cardboard

Flexographic printing excels in cardboard packaging due to its high-speed production capabilities, ability to print on corrugated surfaces, and cost-effectiveness for large runs. Lithographic printing delivers superior image quality and color accuracy, making it ideal for detailed graphic designs on smooth cardboard sheets. Selecting the best printing method depends on the cardboard type, desired print quality, production volume, and budget constraints.

Flexographic printing vs Lithographic printing Infographic

materialdif.com

materialdif.com