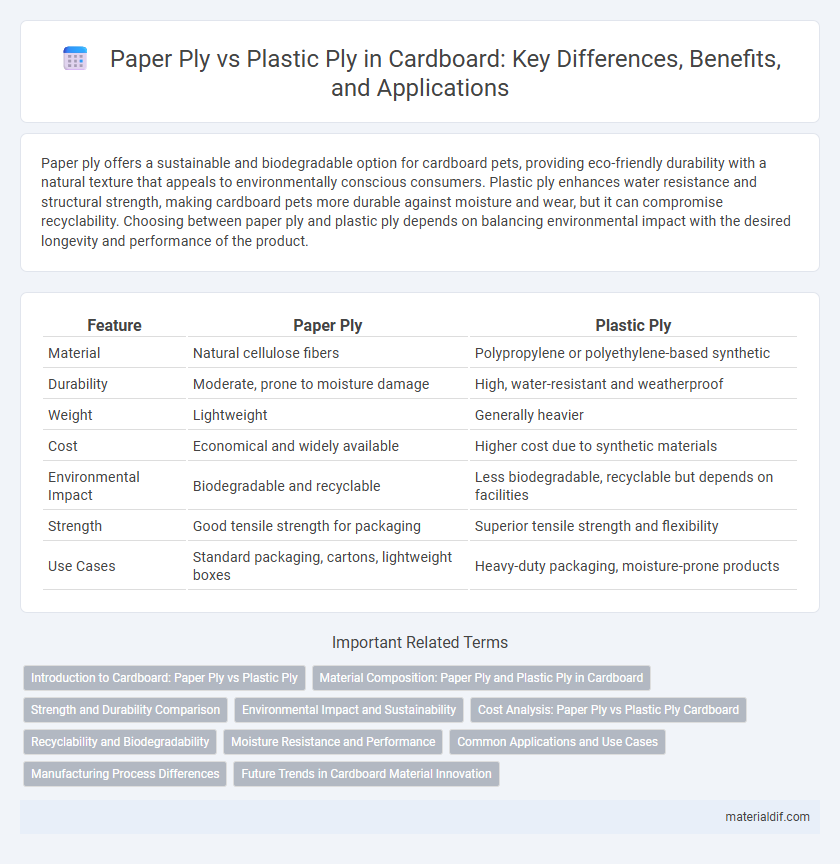

Paper ply offers a sustainable and biodegradable option for cardboard pets, providing eco-friendly durability with a natural texture that appeals to environmentally conscious consumers. Plastic ply enhances water resistance and structural strength, making cardboard pets more durable against moisture and wear, but it can compromise recyclability. Choosing between paper ply and plastic ply depends on balancing environmental impact with the desired longevity and performance of the product.

Table of Comparison

| Feature | Paper Ply | Plastic Ply |

|---|---|---|

| Material | Natural cellulose fibers | Polypropylene or polyethylene-based synthetic |

| Durability | Moderate, prone to moisture damage | High, water-resistant and weatherproof |

| Weight | Lightweight | Generally heavier |

| Cost | Economical and widely available | Higher cost due to synthetic materials |

| Environmental Impact | Biodegradable and recyclable | Less biodegradable, recyclable but depends on facilities |

| Strength | Good tensile strength for packaging | Superior tensile strength and flexibility |

| Use Cases | Standard packaging, cartons, lightweight boxes | Heavy-duty packaging, moisture-prone products |

Introduction to Cardboard: Paper Ply vs Plastic Ply

Cardboard consists primarily of layers called plies, which can be made from paper or plastic materials, each offering distinct advantages. Paper ply, derived from cellulose fibers, provides excellent recyclability and cost-effectiveness, making it ideal for sustainable packaging solutions. Plastic ply enhances durability and moisture resistance, suitable for applications requiring increased strength and protection against environmental factors.

Material Composition: Paper Ply and Plastic Ply in Cardboard

Paper ply in cardboard consists primarily of cellulose fibers derived from wood pulp, offering biodegradability and recyclability. Plastic ply incorporates polymers such as polyethylene or polypropylene, enhancing water resistance and durability but reducing eco-friendliness. The material composition difference between paper ply and plastic ply directly impacts cardboard's environmental footprint and application suitability.

Strength and Durability Comparison

Paper ply cardboard offers moderate strength and is biodegradable, making it environmentally friendly but less resistant to moisture and impact. Plastic ply cardboard provides superior durability and load-bearing capacity due to its water-resistant and tear-proof qualities, ideal for heavy-duty packaging. The choice between paper ply and plastic ply hinges on the required strength and exposure conditions of the application.

Environmental Impact and Sustainability

Paper ply in cardboard is typically more environmentally sustainable due to its biodegradability and higher recyclability compared to plastic ply, which can persist in landfills for decades. The production of paper ply generally uses renewable resources and often incorporates recycled fibers, reducing deforestation and carbon emissions. Plastic ply, derived from petrochemicals, contributes to microplastic pollution and demands more energy-intensive manufacturing processes, negatively impacting the overall ecological footprint.

Cost Analysis: Paper Ply vs Plastic Ply Cardboard

Paper ply cardboard generally offers a lower production cost compared to plastic ply due to the affordability of raw materials like recycled paper fibers and simpler manufacturing processes. Plastic ply cardboard, while more expensive, provides enhanced durability and moisture resistance, which can reduce costs related to product damage and increase the lifespan of packaging. Evaluating overall cost-effectiveness involves considering initial material expenses alongside long-term benefits such as reusability and environmental impact.

Recyclability and Biodegradability

Paper ply cardboard demonstrates superior recyclability and biodegradability compared to plastic ply, as it breaks down naturally in composting environments and can be reprocessed multiple times with minimal quality loss. Plastic ply, often derived from polyethylene or polypropylene, poses challenges in recycling due to contamination risk and limited recycling facilities, resulting in longer environmental persistence. Choosing paper ply enhances sustainable packaging solutions by reducing landfill waste and promoting circular economy practices.

Moisture Resistance and Performance

Plastic ply in cardboard offers superior moisture resistance compared to paper ply, significantly reducing water absorption and maintaining structural integrity in humid conditions. This enhanced moisture barrier improves performance in packaging applications requiring durability and protection against moisture damage. Paper ply, while more eco-friendly, tends to absorb moisture, leading to weakening and reduced lifespan under damp environments.

Common Applications and Use Cases

Paper ply is commonly used in packaging, shipping boxes, and retail displays due to its eco-friendly nature and recyclability, making it ideal for single-use or short-term applications. Plastic ply offers superior moisture resistance and durability, which suits long-term use scenarios such as reusable containers, industrial packaging, and protective inserts. Both materials serve distinct purposes where paper ply excels in sustainability-focused products, while plastic ply is preferred for moisture-prone environments and heavy-duty protection.

Manufacturing Process Differences

Paper ply in cardboard manufacturing involves layering cellulose fibers through a pulping and pressing process, resulting in a biodegradable and recyclable material with good rigidity. Plastic ply uses thermoplastic resins molded or extruded into sheets, which are then laminated to add moisture resistance and durability but at the cost of reduced recyclability. The manufacturing of paper ply emphasizes eco-friendly sourcing and energy-efficient drying, whereas plastic ply production requires higher temperatures and involves chemical additives to achieve desired mechanical properties.

Future Trends in Cardboard Material Innovation

Future trends in cardboard material innovation emphasize a shift towards eco-friendly solutions, with paper ply gaining traction due to its recyclability and biodegradability compared to plastic ply. Advances in cellulose nanofiber technology enhance paper ply's strength and durability, making it a competitive alternative to plastic-based layers. Sustainable packaging industries increasingly adopt paper ply to meet regulatory standards and consumer demand for greener materials, driving research in composites that blend eco-efficiency with performance.

Paper ply vs Plastic ply Infographic

materialdif.com

materialdif.com