White-lined chipboard features a smooth, clean white surface ideal for high-quality printing and packaging, offering a more aesthetically pleasing finish compared to greyboard. Greyboard, typically made from recycled materials, is thicker and sturdier but has a rough, uncoated surface suitable for structural support rather than visual appeal. Choosing between these options depends on the balance between presentation needs and durability requirements in packaging design.

Table of Comparison

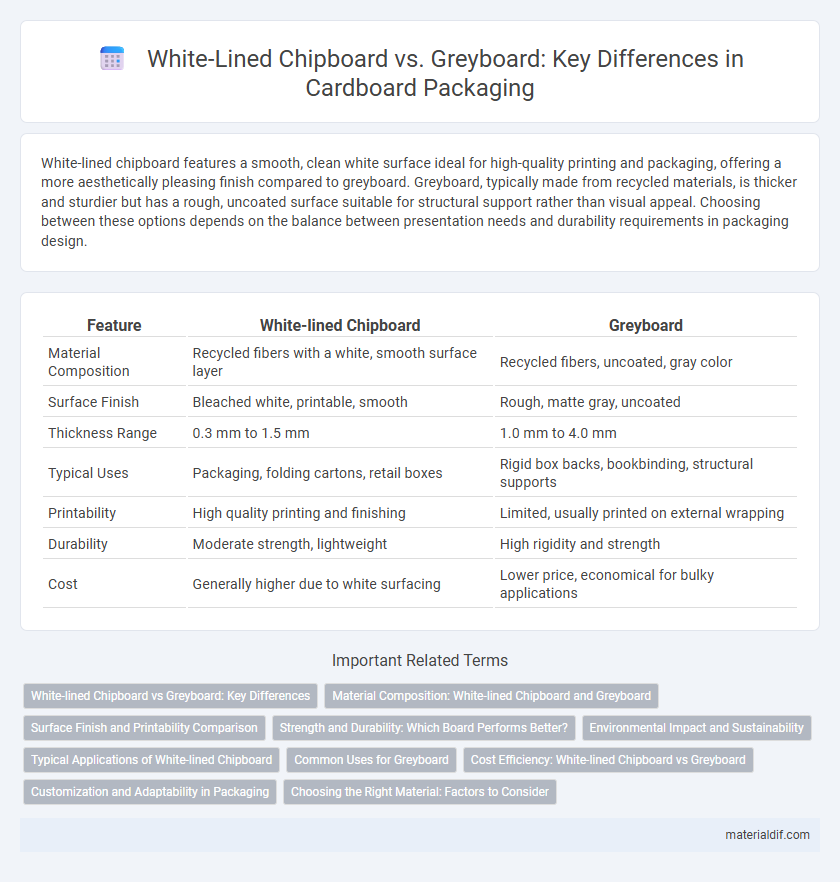

| Feature | White-lined Chipboard | Greyboard |

|---|---|---|

| Material Composition | Recycled fibers with a white, smooth surface layer | Recycled fibers, uncoated, gray color |

| Surface Finish | Bleached white, printable, smooth | Rough, matte gray, uncoated |

| Thickness Range | 0.3 mm to 1.5 mm | 1.0 mm to 4.0 mm |

| Typical Uses | Packaging, folding cartons, retail boxes | Rigid box backs, bookbinding, structural supports |

| Printability | High quality printing and finishing | Limited, usually printed on external wrapping |

| Durability | Moderate strength, lightweight | High rigidity and strength |

| Cost | Generally higher due to white surfacing | Lower price, economical for bulky applications |

White-lined Chipboard vs Greyboard: Key Differences

White-lined chipboard features a white, printable surface ideal for high-quality graphics and packaging, while greyboard consists of recycled paper with a rough, grey finish used mainly for structural applications. White-lined chipboard offers superior visual appeal and smoothness, making it suitable for product packaging and retail displays. Greyboard is more cost-effective and environmentally friendly, often employed for backing, bookbinding, and protective cases where appearance is less critical.

Material Composition: White-lined Chipboard and Greyboard

White-lined chipboard features a smooth, bleached white surface layer made from high-quality recycled fibers, ideal for printing and packaging aesthetics. Greyboard consists primarily of recycled paper pulp with a coarse, uncoated grey surface, providing strength and rigidity for structural applications like bookbinding and box manufacturing. The material composition differences influence the board's appearance, durability, and suitability for various commercial uses.

Surface Finish and Printability Comparison

White-lined chipboard features a smooth, white clay-coated surface that enhances print quality and color vibrancy, making it ideal for high-end packaging requiring detailed graphics. Greyboard, with its uncoated, rougher surface, offers lower print fidelity and is better suited for secondary packaging or structural uses where aesthetics are less critical. The superior surface finish of white-lined chipboard allows for sharper image reproduction and more consistent ink adhesion compared to the porous texture of greyboard.

Strength and Durability: Which Board Performs Better?

White-lined chipboard offers a smoother surface and better printability but generally has lower strength and durability compared to greyboard, which is thicker and denser, making it ideal for heavy-duty packaging. Greyboard's higher rigidity and impact resistance ensure superior performance in protecting contents from damage, especially in shipping and storage applications. For applications requiring robustness and long-term durability, greyboard outperforms white-lined chipboard in structural integrity and resilience.

Environmental Impact and Sustainability

White-lined chipboard is often favored for its recyclability and use of recycled fibers, making it a more sustainable option compared to greyboard, which generally contains a higher proportion of virgin fibers and less recycled content. The production of white-lined chipboard involves lower energy consumption and reduced greenhouse gas emissions due to its lighter weight and efficient recycling processes. Greyboard, while durable, poses greater environmental challenges due to its heavier composition and limited recyclability, which can result in increased landfill waste.

Typical Applications of White-lined Chipboard

White-lined chipboard is commonly used for retail packaging, such as cosmetics, food containers, and pharmaceutical boxes, due to its smooth, printable surface and high-quality finish. Its durability and excellent printability make it ideal for product packaging that requires vibrant graphics and branding. Unlike greyboard, which is primarily used in bookbinding and backing applications, white-lined chipboard offers a more refined appearance suitable for consumer-facing products.

Common Uses for Greyboard

Greyboard is primarily used in packaging for premium products such as luxury boxes, book covers, backing for notepads, and rigid boxes due to its high stiffness and durability. Its robust structure makes it ideal for applications requiring strong protection and a smooth surface for printing or lamination. Unlike white-lined chipboard, greyboard often serves as the core material that can be covered with decorative layers for aesthetic appeal.

Cost Efficiency: White-lined Chipboard vs Greyboard

White-lined chipboard offers superior cost efficiency compared to greyboard due to its lighter weight and lower raw material costs, making it ideal for packaging that requires high-quality printing at a reduced expense. Greyboard, typically more expensive, is denser and heavier, providing enhanced durability but increasing transportation and overall production costs. Choosing white-lined chipboard can significantly reduce expenses in applications where durability is less critical, optimizing budget allocation for packaging projects.

Customization and Adaptability in Packaging

White-lined chipboard offers superior customization and adaptability in packaging due to its smooth, printable surface that supports high-quality graphics and branding elements. Greyboard, typically used for structural strength, is less adaptable for detailed customization but excels in providing rigid support and protection. Choosing between the two depends on the balance needed between aesthetic appeal and durability in packaging design.

Choosing the Right Material: Factors to Consider

White-lined chipboard offers a cleaner, more polished appearance with a smooth white surface ideal for high-quality printing and packaging, while greyboard provides superior strength and durability for structural applications. Consider the end use, weight requirements, and visual appeal; white-lined chipboard is best for retail packaging where aesthetics matter, whereas greyboard suits protective packaging and bookbinding due to its robustness. Cost and environmental impact also influence the choice, with greyboard often being more economical and recyclable, whereas white-lined chipboard tends to be pricier but visually appealing.

White-lined chipboard vs Greyboard Infographic

materialdif.com

materialdif.com