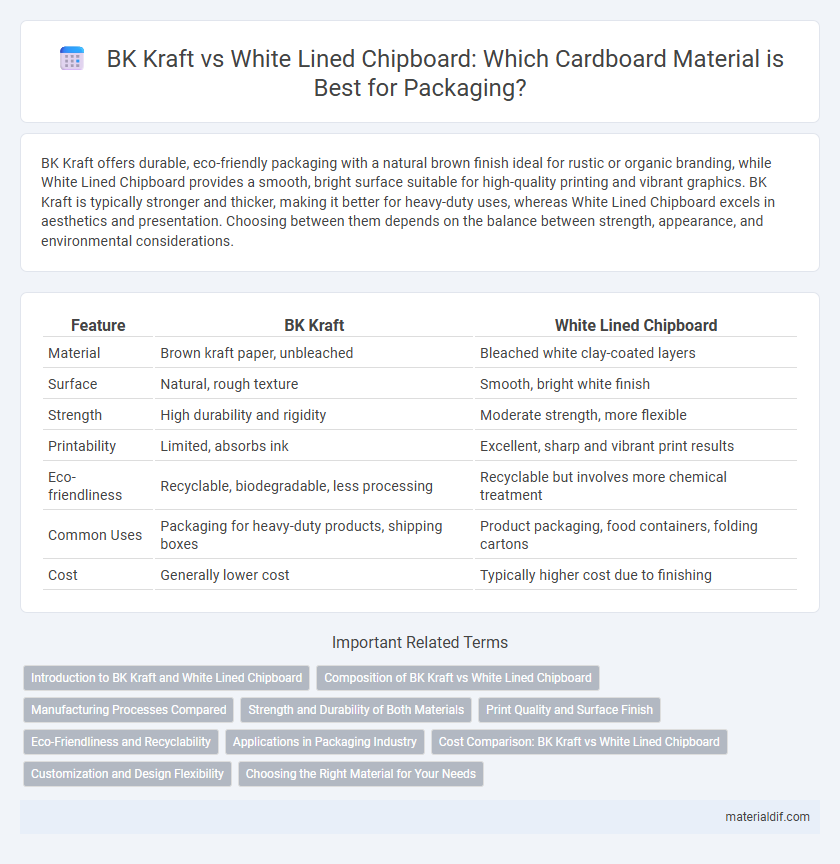

BK Kraft offers durable, eco-friendly packaging with a natural brown finish ideal for rustic or organic branding, while White Lined Chipboard provides a smooth, bright surface suitable for high-quality printing and vibrant graphics. BK Kraft is typically stronger and thicker, making it better for heavy-duty uses, whereas White Lined Chipboard excels in aesthetics and presentation. Choosing between them depends on the balance between strength, appearance, and environmental considerations.

Table of Comparison

| Feature | BK Kraft | White Lined Chipboard |

|---|---|---|

| Material | Brown kraft paper, unbleached | Bleached white clay-coated layers |

| Surface | Natural, rough texture | Smooth, bright white finish |

| Strength | High durability and rigidity | Moderate strength, more flexible |

| Printability | Limited, absorbs ink | Excellent, sharp and vibrant print results |

| Eco-friendliness | Recyclable, biodegradable, less processing | Recyclable but involves more chemical treatment |

| Common Uses | Packaging for heavy-duty products, shipping boxes | Product packaging, food containers, folding cartons |

| Cost | Generally lower cost | Typically higher cost due to finishing |

Introduction to BK Kraft and White Lined Chipboard

BK Kraft is a type of kraft paper known for its durability and natural brown color, commonly used in packaging due to its strength and resistance to tearing. White Lined Chipboard (WLC) consists of recycled paperboard layers with a white, smooth outer lining that enhances printability and visual appeal for retail packaging. Both materials offer specific advantages: BK Kraft excels in robustness and eco-friendliness, while White Lined Chipboard provides superior surface quality and aesthetic versatility.

Composition of BK Kraft vs White Lined Chipboard

BK Kraft cardboard is primarily composed of recycled fibers and unbleached wood pulp, giving it a natural brown color and high durability. White lined chipboard combines recycled greyboard cores with multiple layers of bleached, white paper liners on the surface, offering a smooth, printable finish. The difference in composition affects their strength, appearance, and suitability for packaging and printing applications.

Manufacturing Processes Compared

BK Kraft cardboard is produced through a kraft pulping process that yields stronger fibers and greater durability, ideal for heavy-duty packaging. White lined chipboard involves recycling layers of paper and cardboard, with a thinner top white clay coating to enhance printability but resulting in lower strength compared to kraft. Manufacturing BK Kraft emphasizes fiber strength and resilience, while white lined chipboard focuses on cost-efficiency and surface finish through multiple recycled layers.

Strength and Durability of Both Materials

BK Kraft cardboard offers superior strength and durability due to its dense fiber composition and natural kraft fibers, making it resistant to tearing and puncturing. White lined chipboard, while providing a smooth, attractive surface for printing, generally has lower tensile strength and is more prone to wear and damage under heavy loads or moisture exposure. For applications requiring robust support and longevity, BK Kraft outperforms white lined chipboard in maintaining structural integrity over time.

Print Quality and Surface Finish

BK Kraft board offers a natural, rustic surface with moderate print quality due to its uncoated, porous texture, making it ideal for eco-friendly packaging with a raw aesthetic. White lined chipboard provides a smooth, coated surface that enhances print sharpness and color vibrancy, delivering superior print quality and a polished finish for high-end product presentation. The choice between BK Kraft and white lined chipboard depends on the desired visual impact and branding requirements, balancing rustic charm against sleek professionalism.

Eco-Friendliness and Recyclability

BK Kraft board is highly eco-friendly due to its unbleached, natural fibers and minimal chemical processing, making it fully recyclable and biodegradable. White lined chipboard (WLC) often contains bleached fibers and coatings that can complicate recycling and increase environmental impact. Choosing BK Kraft over WLC reduces carbon footprint and supports sustainable packaging practices by promoting circular economy principles.

Applications in Packaging Industry

BK Kraft offers superior strength and durability compared to White Lined Chipboard, making it ideal for heavy-duty packaging such as shipping boxes, industrial containers, and protective packaging. White Lined Chipboard excels in retail packaging due to its smooth printable surface, vibrant graphics, and lightweight nature, preferred for products like cereal boxes, cosmetics, and point-of-purchase displays. Both materials play significant roles in the packaging industry, with BK Kraft ensuring structural integrity and White Lined Chipboard delivering high-quality visual appeal.

Cost Comparison: BK Kraft vs White Lined Chipboard

BK Kraft board generally costs less than white lined chipboard due to its simpler manufacturing process and lower-quality raw materials. White lined chipboard, featuring a smooth, printable surface and superior finish, commands a higher price but is preferred for premium packaging applications. When balancing budget and presentation, BK Kraft offers a cost-effective solution for basic packaging needs, while white lined chipboard justifies its premium cost with enhanced aesthetic and print quality.

Customization and Design Flexibility

BK Kraft offers superior customization and design flexibility compared to White Lined Chipboard, allowing for a wide range of finishes, textures, and printing options tailored to specific branding needs. BK Kraft's natural brown surface provides an authentic, eco-friendly appearance, which can be easily customized with various coatings and embossing techniques. White Lined Chipboard, while smooth and ideal for high-quality graphic printing, offers less versatility in terms of surface texture and eco-conscious customization options.

Choosing the Right Material for Your Needs

BK Kraft offers superior strength and durability due to its unbleached, natural fibers, making it ideal for heavy-duty packaging and eco-friendly products. White lined chipboard features a smooth, white surface suitable for high-quality printing and retail packaging where aesthetics are crucial. Selecting between BK Kraft and white lined chipboard depends on prioritizing either structural strength or visual appeal for your specific packaging requirements.

BK Kraft vs White lined chipboard Infographic

materialdif.com

materialdif.com