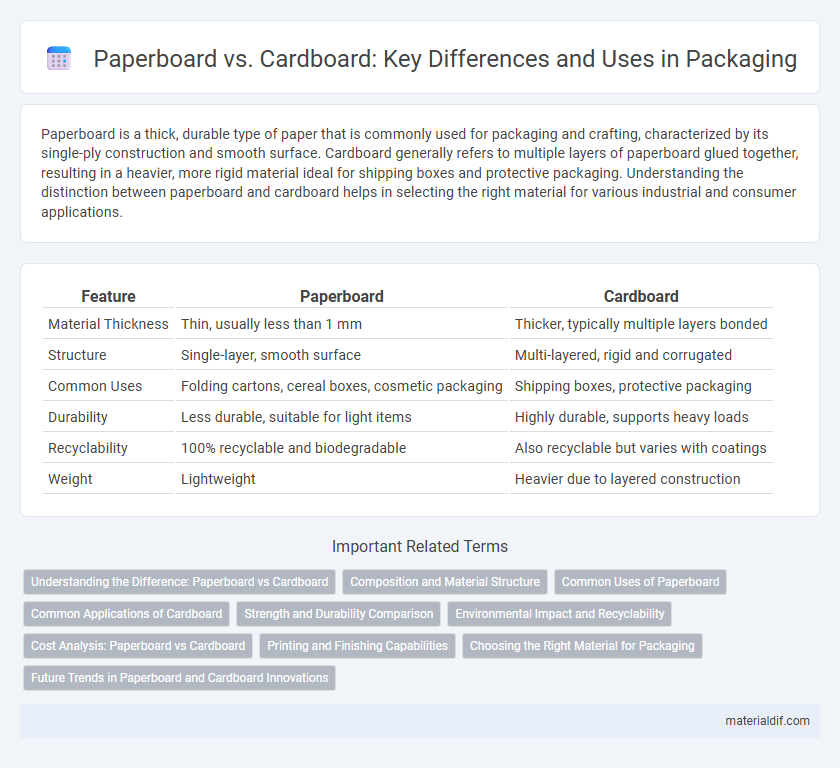

Paperboard is a thick, durable type of paper that is commonly used for packaging and crafting, characterized by its single-ply construction and smooth surface. Cardboard generally refers to multiple layers of paperboard glued together, resulting in a heavier, more rigid material ideal for shipping boxes and protective packaging. Understanding the distinction between paperboard and cardboard helps in selecting the right material for various industrial and consumer applications.

Table of Comparison

| Feature | Paperboard | Cardboard |

|---|---|---|

| Material Thickness | Thin, usually less than 1 mm | Thicker, typically multiple layers bonded |

| Structure | Single-layer, smooth surface | Multi-layered, rigid and corrugated |

| Common Uses | Folding cartons, cereal boxes, cosmetic packaging | Shipping boxes, protective packaging |

| Durability | Less durable, suitable for light items | Highly durable, supports heavy loads |

| Recyclability | 100% recyclable and biodegradable | Also recyclable but varies with coatings |

| Weight | Lightweight | Heavier due to layered construction |

Understanding the Difference: Paperboard vs Cardboard

Paperboard is a thick, paper-based material typically used for packaging lightweight goods, characterized by its smooth surface and uniform thickness, making it ideal for printing and folding. Cardboard, often a generic term, generally refers to various heavy-duty paper-based materials including corrugated fiberboard, which features multiple layers for enhanced strength used in shipping containers. Understanding the distinction involves recognizing paperboard's single-layer structure suited for retail packaging versus cardboard's layered construction designed for durability and protection during transport.

Composition and Material Structure

Paperboard consists of multiple layers of pulp fibers pressed together, creating a dense and smooth surface ideal for printing and packaging. Cardboard typically refers to thicker, more rigid material made from several layers of paperboard that are bonded together, often including a corrugated layer for added strength and cushioning. The structural composition of cardboard enhances durability and impact resistance compared to single-layer paperboard.

Common Uses of Paperboard

Paperboard is commonly used for packaging lightweight products such as cereal boxes, folding cartons, and cosmetic packaging due to its smooth surface and printability. Its stiffness and durability make it ideal for items requiring protection and aesthetic appeal, including pharmaceutical packaging and food containers. Unlike cardboard, paperboard is thinner and more refined, making it suitable for detailed graphics and branding applications.

Common Applications of Cardboard

Cardboard is widely used in packaging for shipping boxes, product displays, and protective packaging due to its durability and lightweight properties. It frequently serves in food containers, such as cereal boxes and takeout boxes, providing sturdy yet recyclable solutions. Cardboard's versatility also extends to crafting, storage bins, and signage, making it essential across industries requiring sustainable and cost-effective materials.

Strength and Durability Comparison

Paperboard typically offers a lighter and smoother surface, making it ideal for packaging that requires printing quality but moderate strength. Cardboard, especially corrugated types, provides superior strength and durability due to its multi-layered construction, making it better suited for heavy-duty shipping and protection. The fluted inner layer in corrugated cardboard significantly enhances its resistance to compression, impact, and bending compared to paperboard.

Environmental Impact and Recyclability

Paperboard and cardboard differ significantly in environmental impact and recyclability, with paperboard generally being thinner, lighter, and easier to recycle due to its simpler fiber composition. Cardboard, often thicker and composed of multiple layers, may require more intensive processing but still remains widely recyclable in most municipal systems. Both materials contribute to sustainable packaging when sourced from responsibly managed forests and properly recycled, reducing landfill waste and conserving raw materials.

Cost Analysis: Paperboard vs Cardboard

Paperboard generally offers a lower production cost compared to cardboard due to its thinner structure and simpler manufacturing process, making it cost-effective for lightweight packaging. Cardboard, while more expensive, provides greater durability and structural strength, justifying its higher price for heavy-duty or protective packaging applications. Analyzing the cost-benefit ratio reveals that paperboard suits budget-sensitive projects requiring moderate protection, whereas cardboard is preferable for high-value goods needing robust containment.

Printing and Finishing Capabilities

Paperboard offers superior printing and finishing capabilities compared to cardboard due to its smoother surface and higher density, allowing for crisper, more detailed print quality. It supports advanced finishing techniques such as embossing, foil stamping, and matte or gloss coatings, enhancing visual appeal and durability. Cardboard, typically rougher and more porous, is less suited for high-end printing but remains cost-effective for simple packaging needs.

Choosing the Right Material for Packaging

Paperboard and cardboard differ primarily in thickness and durability, with paperboard being thinner, more rigid, and ideal for lightweight packaging like cereal boxes, while cardboard is thicker, stronger, and suited for heavy-duty shipping containers. Choosing the right material depends on the product's protection requirements, weight, and sustainability preferences, as paperboard often offers better printability and recycling options. Understanding these characteristics ensures optimal packaging performance, cost-efficiency, and environmental impact.

Future Trends in Paperboard and Cardboard Innovations

Future trends in paperboard and cardboard innovations emphasize sustainability and enhanced functionality, with advancements in biodegradable coatings and lightweight structural designs leading the market. Emerging technologies focus on improving recyclability and integrating smart features such as embedded sensors for supply chain tracking. The global push toward eco-friendly packaging solutions is driving research into renewable materials and manufacturing processes that reduce carbon footprints.

Paperboard vs Cardboard Infographic

materialdif.com

materialdif.com