Single-wall cardboard consists of one layer of corrugated medium between two liners, offering lightweight protection ideal for shipping less fragile items. Double-wall cardboard features two layers of corrugated medium and three liners, providing enhanced strength and durability for heavier or more fragile shipments. Choosing between single-wall and double-wall cardboard depends on the required protection level and the weight of the contents being shipped.

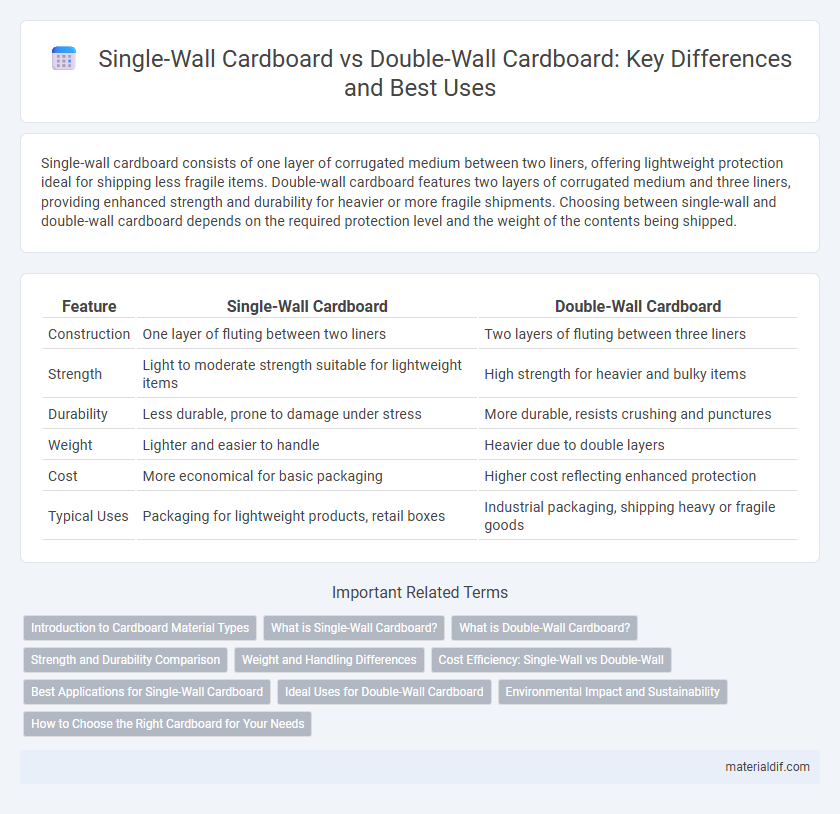

Table of Comparison

| Feature | Single-Wall Cardboard | Double-Wall Cardboard |

|---|---|---|

| Construction | One layer of fluting between two liners | Two layers of fluting between three liners |

| Strength | Light to moderate strength suitable for lightweight items | High strength for heavier and bulky items |

| Durability | Less durable, prone to damage under stress | More durable, resists crushing and punctures |

| Weight | Lighter and easier to handle | Heavier due to double layers |

| Cost | More economical for basic packaging | Higher cost reflecting enhanced protection |

| Typical Uses | Packaging for lightweight products, retail boxes | Industrial packaging, shipping heavy or fragile goods |

Introduction to Cardboard Material Types

Single-wall cardboard consists of one layer of fluted corrugation between two liners, offering lightweight protection suitable for small to medium packages. Double-wall cardboard features two layers of fluted corrugation sandwiched between three liners, providing enhanced strength and durability for heavier or fragile shipments. Choosing between single-wall and double-wall cardboard depends on the required load capacity, protection level, and shipping conditions.

What is Single-Wall Cardboard?

Single-wall cardboard consists of a single layer of fluted paper sandwiched between two flat linerboards, making it lightweight and flexible. It is commonly used for packaging lighter items such as retail boxes, shipping cartons, and product displays. Single-wall cardboard offers sufficient protection for everyday shipping needs but provides less strength compared to double-wall cardboard.

What is Double-Wall Cardboard?

Double-wall cardboard consists of two layers of corrugated medium sandwiched between three sheets of linerboard, providing enhanced strength and durability compared to single-wall cardboard. It is designed to withstand heavier loads and offers superior resistance to impacts, making it ideal for shipping fragile or bulky items. Commonly used in industrial packaging and long-distance shipping, double-wall cardboard ensures better protection during transit and storage.

Strength and Durability Comparison

Single-wall cardboard offers moderate strength suitable for lightweight packaging, while double-wall cardboard features two layers of corrugated medium, significantly enhancing its structural integrity and load-bearing capacity. Double-wall cardboard's increased thickness provides superior resistance to crushing, punctures, and stacking pressure, making it ideal for heavy or fragile items. The reinforced construction of double-wall cardboard ensures greater durability during transportation and storage, reducing the risk of damage compared to single-wall options.

Weight and Handling Differences

Single-wall cardboard is lighter, making it easier to handle and ideal for packaging lightweight items that require quick assembly and minimal shipping weight. Double-wall cardboard, with its two layers of fluted material, offers significantly greater strength and durability but increases the overall weight, which may require more effort during handling and transport. The weight difference directly affects shipping costs and the suitability of each type for different product protection needs.

Cost Efficiency: Single-Wall vs Double-Wall

Single-wall cardboard typically offers greater cost efficiency due to lower material and production expenses, making it ideal for lightweight packaging needs. Double-wall cardboard, while more expensive, provides enhanced durability and protection, justifying its higher cost for shipping heavier or fragile items. Choosing between single-wall and double-wall cardboard depends on balancing budget constraints with the required strength and protection level.

Best Applications for Single-Wall Cardboard

Single-wall cardboard is ideal for lightweight packaging needs such as shipping books, clothing, and small consumer electronics where protection against minor impacts and stacking is sufficient. It is cost-effective, easy to fold, and offers good printability for branding purposes on retail packaging. This type of cardboard excels in applications requiring moderate strength and flexibility without the bulk or weight of double-wall corrugated options.

Ideal Uses for Double-Wall Cardboard

Double-wall cardboard features two layers of fluted paperboard, providing enhanced strength and durability compared to single-wall cardboard, making it ideal for heavy or fragile items. It is commonly used in shipping large appliances, industrial equipment, and bulkier products that require additional protection during transit. This type of cardboard also excels in stacking strength, preventing damage from compression in warehouse storage and transportation.

Environmental Impact and Sustainability

Single-wall cardboard uses fewer raw materials and requires less energy to produce, resulting in a lower carbon footprint compared to double-wall cardboard. Double-wall cardboard, while more durable and protective, consumes more resources and generates higher waste during manufacturing and disposal processes. Choosing single-wall cardboard supports environmental sustainability by promoting reduced material consumption and easier recycling.

How to Choose the Right Cardboard for Your Needs

Single-wall cardboard offers lightweight and cost-effective packaging ideal for lighter items and short-term storage, while double-wall cardboard provides enhanced strength and durability necessary for heavier or fragile goods. Consider the weight, fragility of your products, and the shipping or storage conditions to determine the appropriate board type. Choosing the right cardboard ensures product protection, cost efficiency, and suitability for your specific logistical requirements.

Single-wall cardboard vs Double-wall cardboard Infographic

materialdif.com

materialdif.com