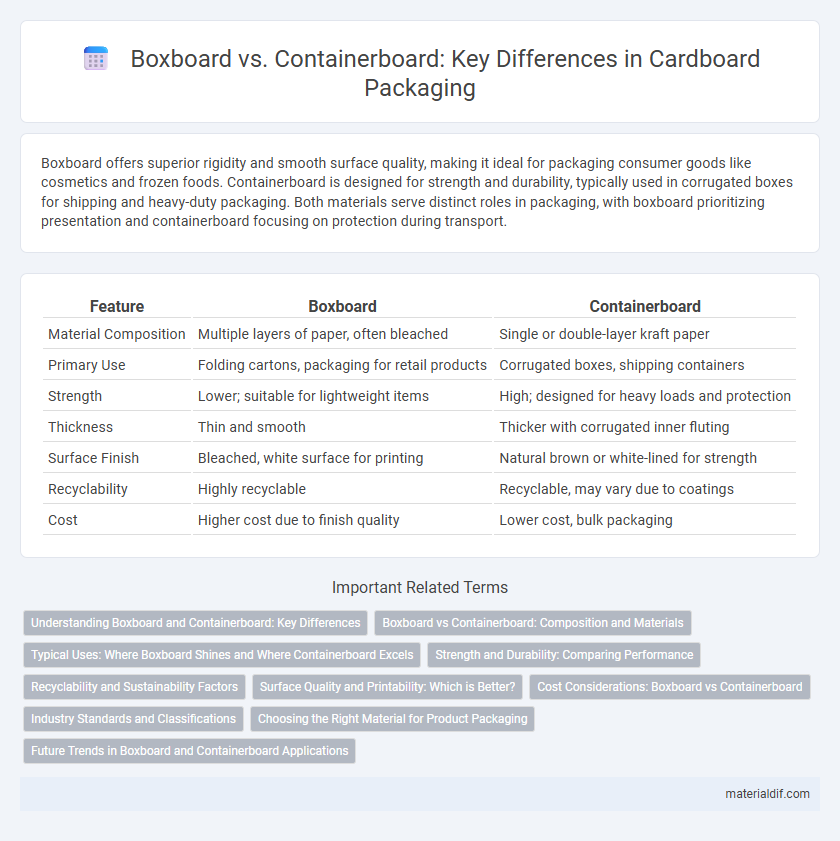

Boxboard offers superior rigidity and smooth surface quality, making it ideal for packaging consumer goods like cosmetics and frozen foods. Containerboard is designed for strength and durability, typically used in corrugated boxes for shipping and heavy-duty packaging. Both materials serve distinct roles in packaging, with boxboard prioritizing presentation and containerboard focusing on protection during transport.

Table of Comparison

| Feature | Boxboard | Containerboard |

|---|---|---|

| Material Composition | Multiple layers of paper, often bleached | Single or double-layer kraft paper |

| Primary Use | Folding cartons, packaging for retail products | Corrugated boxes, shipping containers |

| Strength | Lower; suitable for lightweight items | High; designed for heavy loads and protection |

| Thickness | Thin and smooth | Thicker with corrugated inner fluting |

| Surface Finish | Bleached, white surface for printing | Natural brown or white-lined for strength |

| Recyclability | Highly recyclable | Recyclable, may vary due to coatings |

| Cost | Higher cost due to finish quality | Lower cost, bulk packaging |

Understanding Boxboard and Containerboard: Key Differences

Boxboard is a lightweight, folded paperboard commonly used for retail packaging and consumer goods due to its smooth surface and printability, while containerboard is a heavier, thicker material primarily used for corrugated boxes and shipping containers because of its strength and durability. The primary difference lies in structure and application: boxboard typically consists of multiple layered paper sheets for rigidity and a clean appearance, whereas containerboard includes a linerboard and corrugated medium designed to cushion and protect heavy items during transport. Understanding these distinctions helps manufacturers select the appropriate material to balance cost, protection, and presentation in packaging solutions.

Boxboard vs Containerboard: Composition and Materials

Boxboard typically consists of multiple layers of bleached or unbleached high-quality pulp fibers, providing a smooth surface ideal for printing and packaging applications. Containerboard, mainly used for corrugated boxes, is composed of kraft linerboard and corrugating medium made from stronger, coarser fibers derived from recycled paper or virgin wood pulp to enhance durability and strength. The difference in materials results in boxboard offering superior printability and aesthetic appeal, while containerboard emphasizes structural integrity and resistance to compression.

Typical Uses: Where Boxboard Shines and Where Containerboard Excels

Boxboard excels in packaging for lightweight consumer goods, cosmetics, and pharmaceuticals due to its smooth surface and printability, making it ideal for retail display. Containerboard is preferred for shipping and storage applications, offering superior strength and durability necessary for corrugated boxes used in heavy-duty transport. Each material's typical use is driven by its structural properties and finishing capabilities, ensuring optimized performance in either retail presentation or logistics.

Strength and Durability: Comparing Performance

Boxboard offers superior stiffness and tear resistance, making it ideal for packaging products that require protection against deformation and punctures. Containerboard provides enhanced burst strength and load-bearing capacity, which is essential for heavy-duty shipping and stacking in transportation logistics. Both materials deliver durability tailored to specific applications, with boxboard excelling in consumer-facing packaging and containerboard dominating industrial shipping uses.

Recyclability and Sustainability Factors

Boxboard typically offers higher recyclability due to its lighter coating and fewer composite layers, making it more sustainable for single-use packaging. Containerboard, often used for corrugated boxes, balances strength and recyclability but may require more energy in recycling due to its layered construction. Both materials are widely recyclable, yet boxboard's simpler structure generally results in a lower environmental footprint and easier integration into circular waste management systems.

Surface Quality and Printability: Which is Better?

Boxboard offers superior surface quality with a smoother, more uniform finish ideal for high-quality printing and detailed graphics. Containerboard, designed primarily for durability and strength in shipping, typically has a rougher surface that limits the clarity and vibrancy of printed images. For applications demanding enhanced printability, boxboard is the better choice due to its optimized coating and fiber composition.

Cost Considerations: Boxboard vs Containerboard

Boxboard generally incurs higher production costs due to its finer fibers and multiple layers designed for superior printability and rigidity, making it ideal for retail packaging. Containerboard, predominantly used for corrugated boxes, features a cost-effective construction with recycled fibers and a simpler manufacturing process, optimizing expenses for bulk shipping and transport. When comparing cost considerations, businesses prioritize boxboard for premium packaging despite its price premium, while containerboard offers budget-friendly strength for logistical applications.

Industry Standards and Classifications

Boxboard and containerboard are classified under specific industry standards such as ISO 536 and TAPPI T410, which define their grammage and thickness parameters for packaging applications. Boxboard, typically used in folding cartons and consumer product packaging, is categorized into solid bleached sulfate (SBS), folding boxboard (FBB), and chipboard (CB), emphasizing printability and surface quality. Containerboard, primarily utilized in corrugated fiberboard manufacturing, includes kraft linerboard and corrugating medium, designed to meet strength and durability standards essential for shipping and storage.

Choosing the Right Material for Product Packaging

Boxboard and containerboard differ significantly in structure and application, with boxboard offering a smooth, lightweight surface ideal for high-quality graphic printing and consumer packaging, while containerboard provides durability and strength suited for shipping and heavy-duty protection. Choosing the right material depends on the product's packaging requirements: boxboard excels in retail presentation and light to moderate protection, whereas containerboard ensures resistance to compression and stacking during transit. Evaluating factors such as moisture resistance, printability, and mechanical strength helps optimize packaging performance and cost-effectiveness.

Future Trends in Boxboard and Containerboard Applications

Future trends in boxboard and containerboard applications emphasize sustainability and innovative material enhancements to meet growing environmental regulations. Advanced recycling technologies and bio-based coatings are driving improvements in durability and printability, expanding their use in e-commerce packaging and food-grade containers. Integration of smart packaging with sensors and digital tracking is also becoming prevalent, enabling real-time monitoring and improved supply chain management.

Boxboard vs Containerboard Infographic

materialdif.com

materialdif.com