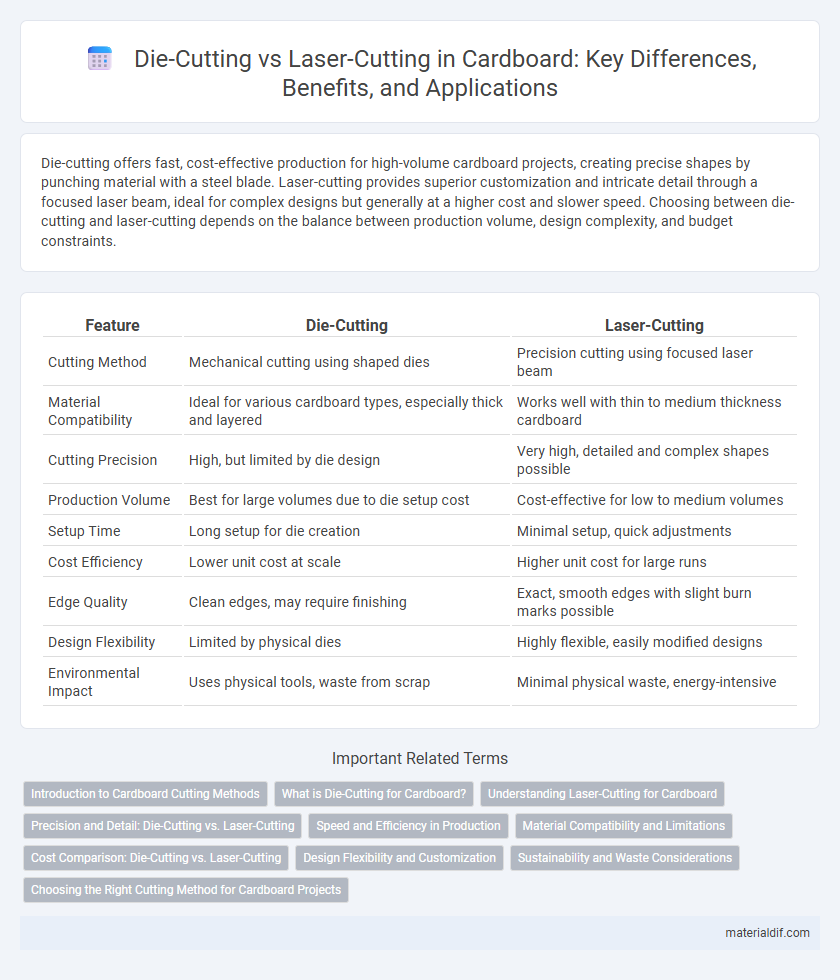

Die-cutting offers fast, cost-effective production for high-volume cardboard projects, creating precise shapes by punching material with a steel blade. Laser-cutting provides superior customization and intricate detail through a focused laser beam, ideal for complex designs but generally at a higher cost and slower speed. Choosing between die-cutting and laser-cutting depends on the balance between production volume, design complexity, and budget constraints.

Table of Comparison

| Feature | Die-Cutting | Laser-Cutting |

|---|---|---|

| Cutting Method | Mechanical cutting using shaped dies | Precision cutting using focused laser beam |

| Material Compatibility | Ideal for various cardboard types, especially thick and layered | Works well with thin to medium thickness cardboard |

| Cutting Precision | High, but limited by die design | Very high, detailed and complex shapes possible |

| Production Volume | Best for large volumes due to die setup cost | Cost-effective for low to medium volumes |

| Setup Time | Long setup for die creation | Minimal setup, quick adjustments |

| Cost Efficiency | Lower unit cost at scale | Higher unit cost for large runs |

| Edge Quality | Clean edges, may require finishing | Exact, smooth edges with slight burn marks possible |

| Design Flexibility | Limited by physical dies | Highly flexible, easily modified designs |

| Environmental Impact | Uses physical tools, waste from scrap | Minimal physical waste, energy-intensive |

Introduction to Cardboard Cutting Methods

Die-cutting and laser-cutting are two primary methods used for shaping cardboard in packaging and design industries. Die-cutting utilizes a pre-shaped metal blade to stamp out specific shapes efficiently, making it ideal for high-volume production with consistent precision. Laser-cutting employs a focused laser beam to cut or engrave intricate patterns and fine details, offering flexibility and customization for complex or low-quantity projects.

What is Die-Cutting for Cardboard?

Die-cutting for cardboard involves using a specialized steel blade to precisely cut, shape, or emboss cardboard sheets into specific designs or packaging forms. This process is highly efficient for mass production, delivering consistent and clean cuts suited for folding cartons, display packaging, and corrugated boxes. It enables rapid, cost-effective manufacturing with minimal material waste, making it ideal for large-scale cardboard production.

Understanding Laser-Cutting for Cardboard

Laser-cutting cardboard offers precise, intricate designs with smooth edges, making it ideal for detailed packaging and custom displays. Unlike die-cutting, which uses fixed molds, laser-cutting uses focused beams to cut complex shapes without physical contact, reducing material waste and setup time. This technology enhances design flexibility, enabling rapid prototyping and short production runs for cardboard products.

Precision and Detail: Die-Cutting vs. Laser-Cutting

Die-cutting offers consistent precision for producing large volumes of cardboard shapes with clean edges and repeatable patterns, ideal for standard designs. Laser-cutting provides superior detail and intricate cuts, enabling complex and delicate patterns that die-cutting cannot achieve. The choice between die-cutting and laser-cutting depends on the required level of precision, volume, and design complexity in cardboard manufacturing.

Speed and Efficiency in Production

Die-cutting offers rapid production speeds ideal for high-volume cardboard manufacturing, using pre-shaped steel blades that cut quickly with minimal setup time. Laser-cutting provides precise, detailed cuts but operates slower than die-cutting, making it more suitable for custom or low-volume runs where intricate designs are required. Efficiency in production favors die-cutting for mass output due to its speed, while laser-cutting excels in flexibility despite longer processing times.

Material Compatibility and Limitations

Die-cutting excels in processing corrugated cardboard and paperboard with high speed and cost efficiency, but it struggles with intricate designs and thicker materials. Laser-cutting offers precision for detailed patterns and can accommodate diverse cardboard types, including laminated and coated variants, though it may cause slight charring and slower production times. Material selection depends on the complexity of the design and the thickness or coating of the cardboard, influencing the choice between die-cutting and laser-cutting methods.

Cost Comparison: Die-Cutting vs. Laser-Cutting

Die-cutting offers a cost-efficient option for high-volume cardboard production due to its reusable steel dies and faster output, significantly reducing per-unit expenses. Laser-cutting, though more expensive per piece because of higher energy consumption and slower speeds, excels in small batch runs and complex designs without the upfront cost of die creation. Choosing between die-cutting and laser-cutting depends on production scale, with die-cutting favored for large quantities and laser-cutting preferred for customization and prototyping.

Design Flexibility and Customization

Die-cutting offers high precision for repetitive shapes and is cost-effective for large production runs, making it ideal for standard cardboard packaging designs with limited customization. Laser-cutting provides unmatched design flexibility, allowing intricate cuts and personalized details with quick turnaround for small batches or prototypes. Customization using laser-cutting enables complex patterns and unique branding elements that die-cutting cannot easily achieve.

Sustainability and Waste Considerations

Die-cutting produces less material waste by efficiently stamping shapes from cardboard sheets, making it a sustainable choice for large-scale packaging production. Laser-cutting, while offering high precision and design flexibility, can generate more heat and fumes, requiring energy-intensive ventilation systems that impact environmental sustainability. Choosing die-cutting minimizes overall waste and energy consumption, aligning better with eco-friendly manufacturing practices for cardboard products.

Choosing the Right Cutting Method for Cardboard Projects

Die-cutting offers precise, high-volume cuts ideal for mass production of cardboard packaging, delivering consistent shapes with minimal waste. Laser-cutting provides exceptional detail and flexibility, perfect for intricate designs and low-volume or prototype cardboard projects. Selecting the right method depends on project scale, design complexity, and budget considerations to optimize efficiency and quality.

Die-cutting vs Laser-cutting Infographic

materialdif.com

materialdif.com