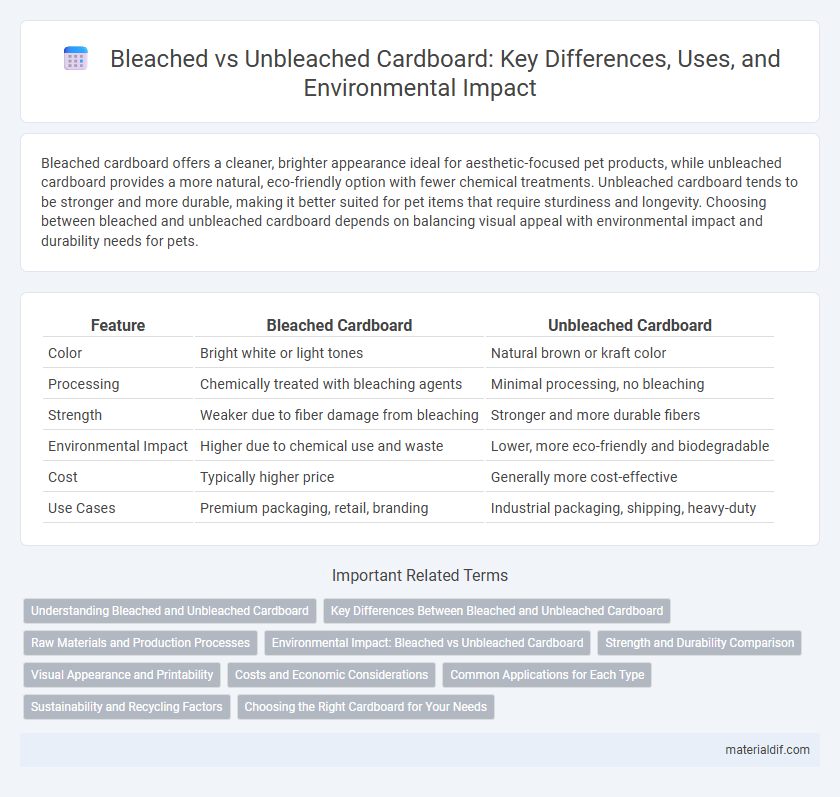

Bleached cardboard offers a cleaner, brighter appearance ideal for aesthetic-focused pet products, while unbleached cardboard provides a more natural, eco-friendly option with fewer chemical treatments. Unbleached cardboard tends to be stronger and more durable, making it better suited for pet items that require sturdiness and longevity. Choosing between bleached and unbleached cardboard depends on balancing visual appeal with environmental impact and durability needs for pets.

Table of Comparison

| Feature | Bleached Cardboard | Unbleached Cardboard |

|---|---|---|

| Color | Bright white or light tones | Natural brown or kraft color |

| Processing | Chemically treated with bleaching agents | Minimal processing, no bleaching |

| Strength | Weaker due to fiber damage from bleaching | Stronger and more durable fibers |

| Environmental Impact | Higher due to chemical use and waste | Lower, more eco-friendly and biodegradable |

| Cost | Typically higher price | Generally more cost-effective |

| Use Cases | Premium packaging, retail, branding | Industrial packaging, shipping, heavy-duty |

Understanding Bleached and Unbleached Cardboard

Bleached cardboard undergoes a chemical whitening process that enhances brightness and smoothness, making it ideal for high-quality printing and packaging. Unbleached cardboard retains its natural brown color and is more environmentally friendly due to fewer chemical treatments, providing durability and a rustic appearance suitable for eco-conscious brands. Understanding these differences helps manufacturers select the appropriate cardboard type based on aesthetic requirements and environmental impact considerations.

Key Differences Between Bleached and Unbleached Cardboard

Bleached cardboard features a whitened surface achieved through chemical treatment, resulting in a smooth, bright finish ideal for high-quality printing and retail packaging. Unbleached cardboard retains its natural brown color and texture, offering greater environmental benefits and enhanced strength for heavy-duty applications. The key differences lie in appearance, environmental impact, and strength, with bleached cardboard favoring aesthetics and unbleached cardboard prioritizing durability and sustainability.

Raw Materials and Production Processes

Bleached cardboard is manufactured from wood pulp that undergoes a chemical bleaching process to remove lignin, resulting in a whiter and smoother surface ideal for high-quality printing. Unbleached cardboard is made from recycled fibers or virgin pulp without bleaching, preserving natural brown tones and retaining more lignin, which enhances its strength and durability. The production of bleached cardboard involves additional chemical treatments and water usage, increasing environmental impact compared to the more eco-friendly, less processed unbleached cardboard.

Environmental Impact: Bleached vs Unbleached Cardboard

Bleached cardboard undergoes chemical treatments that often involve chlorine-based agents, contributing to higher environmental pollution and increased energy consumption compared to unbleached cardboard. Unbleached cardboard retains its natural brown color, reducing the need for harsh chemicals and resulting in a lower carbon footprint and better biodegradability. Choosing unbleached cardboard supports sustainable forestry practices and minimizes harmful waste discharge in paper production.

Strength and Durability Comparison

Bleached cardboard undergoes chemical treatment to remove lignin, resulting in a lighter color but slightly reduced strength due to fiber weakening. Unbleached cardboard retains natural lignin, enhancing durability and resistance to moisture, making it stronger for heavy-duty packaging. For applications requiring maximum strength and longevity, unbleached cardboard provides superior performance compared to bleached options.

Visual Appearance and Printability

Bleached cardboard features a bright white surface that enhances color vibrancy and sharpness, making it ideal for high-quality printing and detailed graphics. Unbleached cardboard has a natural brown tone, which can absorb ink differently and result in muted or less crisp prints but provides a rustic, eco-friendly aesthetic. Printability on bleached cardboard generally offers better contrast and clarity, while unbleached cardboard suits designs that embrace a raw, organic look with lower ink consumption.

Costs and Economic Considerations

Bleached cardboard typically incurs higher production costs due to the chemical processing involved in whitening, making it more expensive than unbleached cardboard. Unbleached cardboard, produced with minimal chemical treatment, offers a cost-effective option for bulk packaging needs and environmentally conscious businesses. Economic considerations favor unbleached cardboard for lower expenses and reduced environmental impact, while bleached cardboard may command higher market prices due to its enhanced aesthetic appeal.

Common Applications for Each Type

Bleached cardboard is commonly used in packaging for food products, cosmetics, and pharmaceuticals due to its clean, white appearance and enhanced printability. Unbleached cardboard is preferred for shipping containers, corrugated boxes, and industrial packaging where strength and durability are prioritized over aesthetics. Both types serve distinct roles in packaging, with bleached cardboard favored for consumer-facing products and unbleached cardboard chosen for heavy-duty, eco-friendly shipping solutions.

Sustainability and Recycling Factors

Bleached cardboard undergoes chemical treatment to achieve a white finish, which can hinder recycling processes due to residual chemicals and increased energy consumption during production. Unbleached cardboard maintains its natural brown color, requiring fewer resources and less chemical use, making it more sustainable and easier to recycle. Choosing unbleached cardboard supports circular economy initiatives by reducing environmental impact and promoting efficient material recovery.

Choosing the Right Cardboard for Your Needs

Bleached cardboard offers a smoother, whiter surface ideal for high-quality printing and retail packaging, while unbleached cardboard provides greater durability and eco-friendliness, often preferred for shipping and storage. Selecting the right cardboard depends on balancing aesthetics, strength, and environmental impact, with bleached cardboard typically used in consumer-facing products and unbleached favored for industrial applications. Consider factors like intended use, branding requirements, and sustainability goals to make an informed choice between bleached and unbleached cardboard.

Bleached cardboard vs Unbleached cardboard Infographic

materialdif.com

materialdif.com