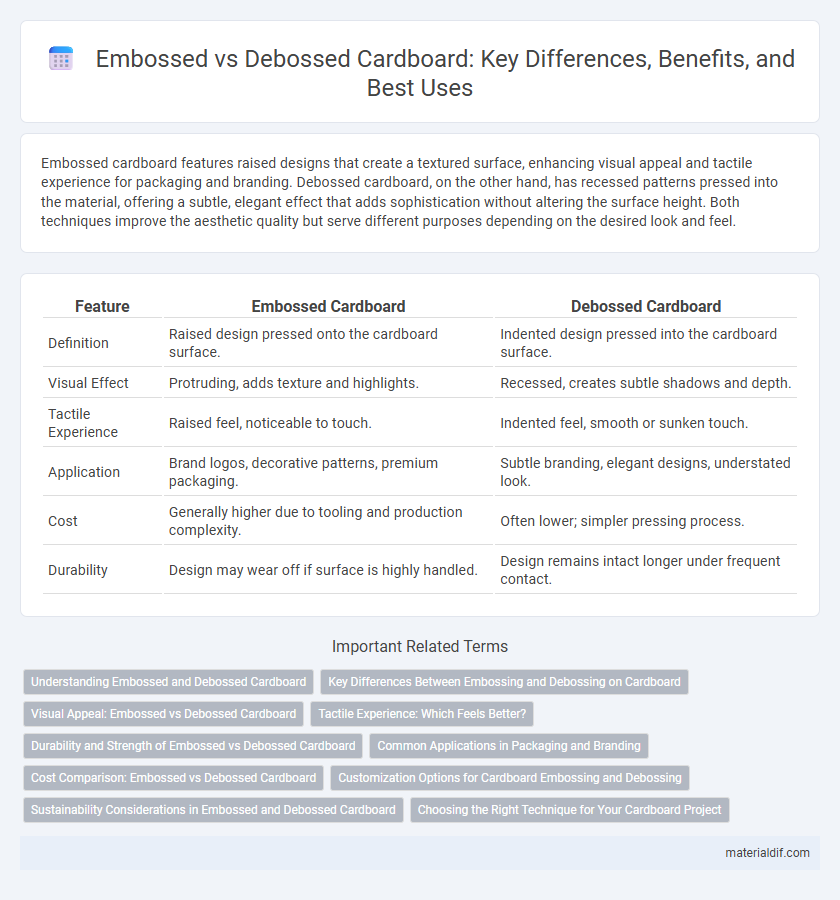

Embossed cardboard features raised designs that create a textured surface, enhancing visual appeal and tactile experience for packaging and branding. Debossed cardboard, on the other hand, has recessed patterns pressed into the material, offering a subtle, elegant effect that adds sophistication without altering the surface height. Both techniques improve the aesthetic quality but serve different purposes depending on the desired look and feel.

Table of Comparison

| Feature | Embossed Cardboard | Debossed Cardboard |

|---|---|---|

| Definition | Raised design pressed onto the cardboard surface. | Indented design pressed into the cardboard surface. |

| Visual Effect | Protruding, adds texture and highlights. | Recessed, creates subtle shadows and depth. |

| Tactile Experience | Raised feel, noticeable to touch. | Indented feel, smooth or sunken touch. |

| Application | Brand logos, decorative patterns, premium packaging. | Subtle branding, elegant designs, understated look. |

| Cost | Generally higher due to tooling and production complexity. | Often lower; simpler pressing process. |

| Durability | Design may wear off if surface is highly handled. | Design remains intact longer under frequent contact. |

Understanding Embossed and Debossed Cardboard

Embossed cardboard features raised patterns or designs that create a three-dimensional texture, enhancing visual appeal and tactile experience for packaging and branding purposes. Debossed cardboard, in contrast, displays recessed or indented designs pressed into the surface, offering a subtle and sophisticated effect that adds depth without altering the material's profile. Understanding the distinction between embossed and debossed cardboard is essential for selecting the right technique to elevate product presentation and protect brand identity.

Key Differences Between Embossing and Debossing on Cardboard

Embossed cardboard features raised designs created by pressing the material from the back, adding texture and dimension that enhances visual appeal and tactile experience. Debossed cardboard, on the other hand, has recessed patterns or text pressed into the surface, producing an indented effect that creates subtle depth and a refined look. These techniques differ primarily in the direction of the impression and the resulting visual and tactile impact on cardboard packaging or products.

Visual Appeal: Embossed vs Debossed Cardboard

Embossed cardboard creates a raised, tactile surface that enhances visual appeal by adding depth and dimension to packaging designs. Debossed cardboard features pressed or recessed patterns that offer a subtle, sophisticated look, emphasizing texture without altering the cardboard's surface height. Both techniques improve branding impact, with embossed cardboard providing a bold, eye-catching effect and debossed cardboard delivering elegance and understated refinement.

Tactile Experience: Which Feels Better?

Embossed cardboard creates a raised texture that stands out to the touch, offering a pronounced tactile sensation that enhances the sense of depth and dimension. Debossed cardboard features recessed designs pressed into the surface, providing a subtle, smooth indent that feels more understated and refined. The choice between embossed and debossed cardboard depends on whether a bold tactile impact or a delicate, elegant touch is preferred for packaging or branding purposes.

Durability and Strength of Embossed vs Debossed Cardboard

Embossed cardboard features raised patterns that reinforce the material's surface, enhancing its durability and resistance to compression compared to debossed cardboard, which has recessed designs that may create slight weak points. The raised texture of embossed cardboard contributes to its structural integrity, making it better suited for packaging that requires extra strength and protection. Debossed cardboard, while offering aesthetic appeal, generally sacrifices some durability due to the indentation weakening the cardboard fibers.

Common Applications in Packaging and Branding

Embossed cardboard features raised designs that enhance tactile appeal and visual depth, making it ideal for luxury packaging, premium product boxes, and brand logos that demand a high-end, sophisticated presentation. Debossed cardboard, with its recessed impressions, offers subtle elegance and is commonly used for minimalist branding, informational text, and understated logos on packaging to create a refined, professional look. Both techniques are essential in packaging design, allowing brands to differentiate products and enhance customer experience through texture and visual contrast.

Cost Comparison: Embossed vs Debossed Cardboard

Embossed cardboard generally incurs higher production costs than debossed cardboard due to the additional tooling and pressure required to raise the design above the surface. Debossed cardboard, which creates sunken impressions, tends to be more cost-effective since it often uses simpler dies and less force during manufacturing. Businesses seeking budget-friendly packaging solutions often prefer debossed designs while embossed options are chosen for premium branding despite the higher expense.

Customization Options for Cardboard Embossing and Debossing

Embossed cardboard features raised designs that add texture and depth, enhancing brand visibility through tactile elements, while debossed cardboard presents recessed images or text for a subtle, elegant effect. Customization options for embossing include varying the depth, shape, and size of raised patterns, as well as combining them with foil stamping or spot UV coatings to create multi-dimensional finishes. Debossing offers versatile customization such as adjusting indentation depth, using detailed line work, and incorporating colored inks or embossing powders to highlight the recessed areas.

Sustainability Considerations in Embossed and Debossed Cardboard

Embossed cardboard uses raised patterns that require precise molding, often increasing material usage and energy consumption, while debossed cardboard involves pressed-in designs that typically demand less material and reduce waste. Both techniques can support sustainable practices when combined with recycled fibers and eco-friendly inks, minimizing environmental impact throughout production. Choosing debossed cardboard frequently offers better resource efficiency and a lower carbon footprint in sustainable packaging solutions.

Choosing the Right Technique for Your Cardboard Project

Embossed cardboard creates raised designs that enhance texture and visual impact, ideal for premium packaging and branding projects requiring tactile appeal. Debossed cardboard, by imprinting recessed patterns, offers a subtle, sophisticated look perfect for understated elegance or minimalist designs. Selecting between embossed and debossed techniques depends on your project's aesthetic goals, budget, and the desired sensory experience for the end-user.

Embossed cardboard vs Debossed cardboard Infographic

materialdif.com

materialdif.com