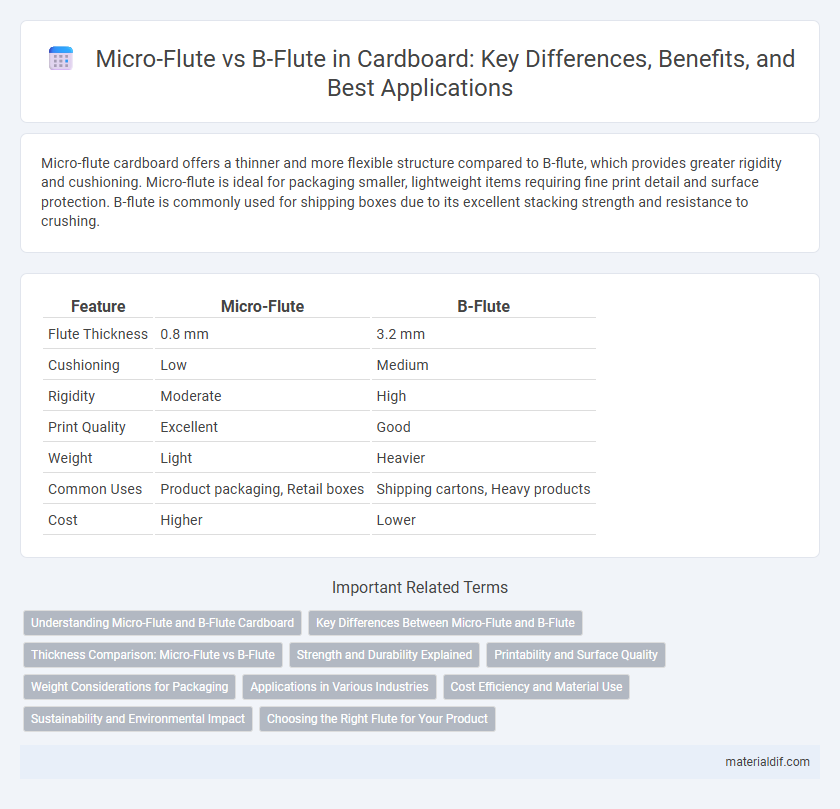

Micro-flute cardboard offers a thinner and more flexible structure compared to B-flute, which provides greater rigidity and cushioning. Micro-flute is ideal for packaging smaller, lightweight items requiring fine print detail and surface protection. B-flute is commonly used for shipping boxes due to its excellent stacking strength and resistance to crushing.

Table of Comparison

| Feature | Micro-Flute | B-Flute |

|---|---|---|

| Flute Thickness | 0.8 mm | 3.2 mm |

| Cushioning | Low | Medium |

| Rigidity | Moderate | High |

| Print Quality | Excellent | Good |

| Weight | Light | Heavier |

| Common Uses | Product packaging, Retail boxes | Shipping cartons, Heavy products |

| Cost | Higher | Lower |

Understanding Micro-Flute and B-Flute Cardboard

Micro-flute cardboard features a finer flute profile, typically around 0.8mm thickness, offering superior printability and smoother surface ideal for high-detail graphics and lightweight packaging. B-flute cardboard, measuring approximately 2.5mm in thickness, provides greater cushioning and rigidity, making it suitable for more durable packaging and shipping applications requiring enhanced protection. Choosing between micro-flute and B-flute depends on balancing the need for print quality, structural strength, and material thickness in packaging design.

Key Differences Between Micro-Flute and B-Flute

Micro-flute cardboard features smaller flutes, approximately 1.6mm in height, providing a smoother surface ideal for high-quality printing and detailed packaging designs. B-flute cardboard, with flute heights around 3.2mm, offers greater cushioning and stacking strength, making it suitable for heavier items and shipping durability. The key differences lie in flute size, printability, and protective performance, influencing the choice based on packaging requirements.

Thickness Comparison: Micro-Flute vs B-Flute

Micro-flute cardboard typically measures around 1.5 mm in thickness, offering a thinner and lighter option compared to B-flute, which averages about 3.2 mm. The thinner profile of micro-flute enhances printability and flexibility, making it ideal for retail packaging and delicate product protection. In contrast, B-flute provides greater cushioning and stacking strength due to its increased thickness, suitable for heavier items and shipping durability.

Strength and Durability Explained

Micro-flute features thinner flutes with higher flute density, providing increased crush resistance and a smoother surface ideal for printing, but it generally offers less cushioning compared to B-flute. B-flute, with thicker and more widely spaced flutes, delivers superior strength and durability, making it better suited for heavy-duty packaging and stacking applications. The choice between micro-flute and B-flute depends on the balance between the need for strength, impact resistance, and print quality in cardboard packaging.

Printability and Surface Quality

Micro-flute cardboard, with a flute thickness of approximately 1.1 mm, offers superior printability and a smoother surface quality ideal for high-resolution graphics and detailed branding. B-flute, measuring about 3.2 mm thick, provides better cushioning but has a rougher surface texture that can affect print clarity and color vibrancy. Choosing micro-flute enhances the visual appeal of packaging by delivering crisp, clean print results on its finer surface.

Weight Considerations for Packaging

Micro-flute cardboard typically weighs less than B-flute, offering a lightweight packaging option without sacrificing strength. B-flute provides greater cushioning and rigidity, which can increase the overall weight but enhances protection for heavier items. Choosing between Micro-flute and B-flute depends on the balance between reducing shipping weight and ensuring adequate product protection.

Applications in Various Industries

Micro-flute cardboard offers superior printability and cushioning, making it ideal for luxury packaging in the electronics and cosmetics industries where aesthetics and protection are critical. B-flute cardboard provides greater stacking strength and shock absorption, commonly used in heavy-duty shipping and storage for automotive parts and industrial equipment. Both flute types enhance product protection but target different industry needs based on durability and presentation requirements.

Cost Efficiency and Material Use

Micro-flute cardboard features a higher flute count with thinner profiles, resulting in better material efficiency and reduced bulk, which lowers transportation and storage costs. B-flute cardboard, with thicker flutes, offers greater cushioning and rigidity but requires more raw material, increasing production expenses. Choosing micro-flute optimizes cost-effectiveness for lightweight packaging, while B-flute is ideal for heavier or more fragile contents needing enhanced protection.

Sustainability and Environmental Impact

Micro-flute cardboard, characterized by its thinner profile and higher flute density, offers enhanced recyclability due to reduced material consumption compared to B-flute cardboard, which has a thicker structure and lower flute density. The environmental impact of micro-flute is generally lower since it requires less raw material and energy in production, contributing to decreased carbon emissions and waste generation. B-flute cardboard, while providing superior cushioning and strength, tends to have a larger environmental footprint because of its increased material usage and more complex recycling process.

Choosing the Right Flute for Your Product

Micro-flute cardboard offers a thinner profile with tighter flute spacing, providing superior surface smoothness ideal for high-quality printing and delicate product packaging. B-flute cardboard features a thicker flute height, delivering enhanced cushioning and crush resistance, making it suitable for heavier or fragile items requiring robust protection during shipping. Selecting the right flute depends on balancing print clarity, structural durability, and product sensitivity to ensure optimal packaging performance.

Micro-flute vs B-flute Infographic

materialdif.com

materialdif.com