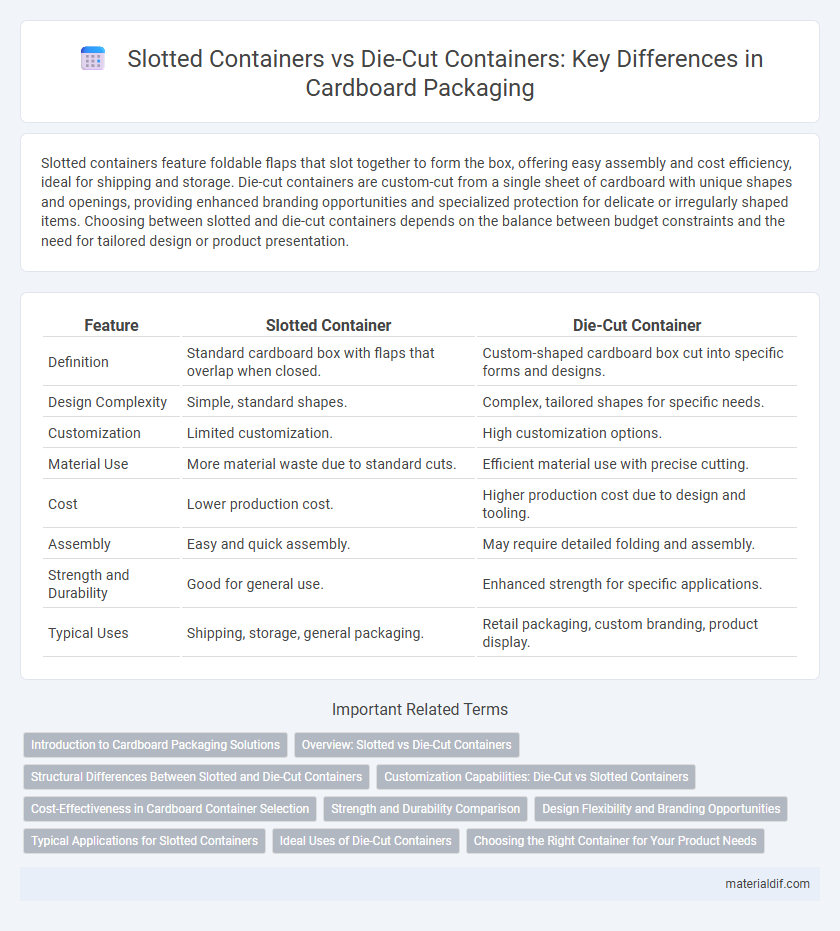

Slotted containers feature foldable flaps that slot together to form the box, offering easy assembly and cost efficiency, ideal for shipping and storage. Die-cut containers are custom-cut from a single sheet of cardboard with unique shapes and openings, providing enhanced branding opportunities and specialized protection for delicate or irregularly shaped items. Choosing between slotted and die-cut containers depends on the balance between budget constraints and the need for tailored design or product presentation.

Table of Comparison

| Feature | Slotted Container | Die-Cut Container |

|---|---|---|

| Definition | Standard cardboard box with flaps that overlap when closed. | Custom-shaped cardboard box cut into specific forms and designs. |

| Design Complexity | Simple, standard shapes. | Complex, tailored shapes for specific needs. |

| Customization | Limited customization. | High customization options. |

| Material Use | More material waste due to standard cuts. | Efficient material use with precise cutting. |

| Cost | Lower production cost. | Higher production cost due to design and tooling. |

| Assembly | Easy and quick assembly. | May require detailed folding and assembly. |

| Strength and Durability | Good for general use. | Enhanced strength for specific applications. |

| Typical Uses | Shipping, storage, general packaging. | Retail packaging, custom branding, product display. |

Introduction to Cardboard Packaging Solutions

Slotted containers, characterized by their simple fold-and-tuck design, offer cost-effective and efficient cardboard packaging solutions ideal for standard shipping needs. Die-cut containers provide customizable shapes and sizes, enabling tailored protection and branding opportunities for specialized products. Both options utilize durable corrugated cardboard, enhancing product safety and sustainability in packaging.

Overview: Slotted vs Die-Cut Containers

Slotted containers feature pre-scored panels that fold into a box shape, offering efficient assembly and cost-effectiveness for packaging needs. Die-cut containers provide custom shapes and intricate designs through precise cutting techniques, enhancing branding and product presentation. Both types balance functionality and aesthetics, with slotted containers favored for durability and die-cut containers chosen for specialized, eye-catching packaging.

Structural Differences Between Slotted and Die-Cut Containers

Slotted containers feature four flaps on the top and bottom that fold and interlock to form the box, providing straightforward assembly and customizable size adjustments. Die-cut containers are created from a single piece of cardboard cut into intricate shapes, allowing for specialized designs with specific slots, tabs, and unique openings for product protection and display. The structural difference centers on complexity and precision, where slotted containers emphasize ease and efficiency, whereas die-cut containers offer tailored, complex structures for enhanced functionality and branding.

Customization Capabilities: Die-Cut vs Slotted Containers

Die-cut containers offer superior customization capabilities compared to slotted containers, allowing intricate shapes, detailed cutouts, and unique structural designs tailored precisely to product specifications. Slotted containers are limited to basic rectangular shapes with standard flaps, providing fewer options for branding and functional adaptations. Custom die-cutting enables enhanced product protection, visual appeal, and tailored inserts, making it ideal for specialized packaging needs in various industries.

Cost-Effectiveness in Cardboard Container Selection

Slotted cardboard containers typically offer greater cost-effectiveness due to their simpler manufacturing process and reduced material waste compared to die-cut containers. Die-cut containers, while providing customized shapes and enhanced design flexibility, often involve higher production costs and longer setup times. Businesses prioritizing budget efficiency often select slotted containers for bulk packaging needs, benefiting from lower expenses and faster turnaround.

Strength and Durability Comparison

Slotted containers, constructed from a single piece of cardboard with overlapping flaps, offer robust strength due to their reinforced edges, making them ideal for heavy or bulky items. Die-cut containers, designed with precise cuts and folds for specialized shapes, provide enhanced structural integrity and durability tailored to specific product protection requirements. The choice between slotted and die-cut containers depends on the balance needed between general load-bearing strength and customized durability for unique packaging needs.

Design Flexibility and Branding Opportunities

Slotted containers offer limited design flexibility due to their standardized shapes, making branding opportunities more constrained with fewer customization options. Die-cut containers provide enhanced design flexibility by allowing unique shapes and intricate cutouts, which enable brands to create visually striking packaging that aligns with their identity. This customization potential makes die-cut containers ideal for businesses seeking distinctive branding and enhanced shelf appeal.

Typical Applications for Slotted Containers

Slotted containers, made from single-sheet cardboard with flaps on the top and bottom, are widely used for shipping, storage, and retail packaging due to their cost-effectiveness and ease of assembly. Typical applications include packaging for electronics, apparel, and food products, where protection and stacking efficiency are essential. These containers provide versatility and strength, making them ideal for bulk shipping and temporary storage solutions.

Ideal Uses of Die-Cut Containers

Die-cut containers excel in packaging specialized products with unique shapes, offering custom dimensions and enhanced protective features compared to standard slotted containers. Their precision design is ideal for fragile items, promotional packaging, and retail displays that require aesthetic appeal and secure fit. Industries such as electronics, cosmetics, and luxury goods benefit from die-cut containers due to their ability to combine durability with visually appealing presentation.

Choosing the Right Container for Your Product Needs

Slotted containers offer easy assembly and are cost-effective for products requiring simple packaging, making them ideal for shipping and storage with standardized sizing. Die-cut containers provide customized shapes and designs, enhancing brand presentation and accommodating unique product dimensions for premium or fragile items. Selecting between slotted and die-cut containers depends on product protection requirements, budget constraints, and marketing strategies to optimize packaging performance.

Slotted container vs Die-cut container Infographic

materialdif.com

materialdif.com