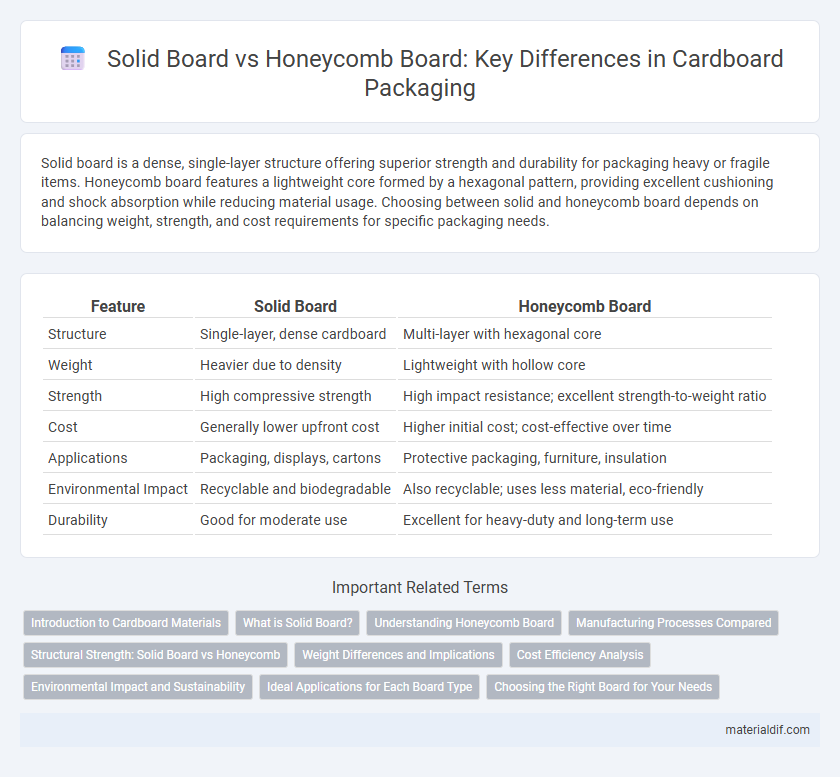

Solid board is a dense, single-layer structure offering superior strength and durability for packaging heavy or fragile items. Honeycomb board features a lightweight core formed by a hexagonal pattern, providing excellent cushioning and shock absorption while reducing material usage. Choosing between solid and honeycomb board depends on balancing weight, strength, and cost requirements for specific packaging needs.

Table of Comparison

| Feature | Solid Board | Honeycomb Board |

|---|---|---|

| Structure | Single-layer, dense cardboard | Multi-layer with hexagonal core |

| Weight | Heavier due to density | Lightweight with hollow core |

| Strength | High compressive strength | High impact resistance; excellent strength-to-weight ratio |

| Cost | Generally lower upfront cost | Higher initial cost; cost-effective over time |

| Applications | Packaging, displays, cartons | Protective packaging, furniture, insulation |

| Environmental Impact | Recyclable and biodegradable | Also recyclable; uses less material, eco-friendly |

| Durability | Good for moderate use | Excellent for heavy-duty and long-term use |

Introduction to Cardboard Materials

Solid board offers a dense and sturdy structure ideal for packaging heavy items, while honeycomb board features a lightweight core with hexagonal cells providing excellent strength-to-weight ratio. Both materials use kraft paper layers but differ significantly in weight, durability, and cushioning properties. Selecting between solid board and honeycomb board depends on packaging requirements such as protection level and transportation efficiency.

What is Solid Board?

Solid board is a type of cardboard made from multiple layers of paperboard pressed together to form a dense, rigid, and durable material commonly used for packaging and display purposes. It offers excellent strength, smooth surface quality, and high printability, making it ideal for luxury packaging, book covers, and rigid boxes. Unlike honeycomb board, solid board provides uniform thickness and enhanced resistance to bending and crushing under heavy loads.

Understanding Honeycomb Board

Honeycomb board features a core composed of hexagonal paper cells that provide exceptional strength and lightweight properties compared to solid board. Its unique structure enhances impact resistance and cushioning, making it ideal for protective packaging and industrial applications. The honeycomb core also offers superior energy absorption and rigidity while reducing material usage and overall weight.

Manufacturing Processes Compared

Solid board is produced by compressing multiple layers of paper fibers, resulting in a dense, rigid material ideal for structural strength and stability. Honeycomb board manufacturing involves creating a core of hexagonal paper cells sandwiched between two liners, providing high strength-to-weight ratio and excellent cushioning properties. The solid board process relies on continuous pressing and drying, while honeycomb board requires precise assembly of the core structure and adhesives for optimal performance.

Structural Strength: Solid Board vs Honeycomb

Solid board demonstrates higher compressive strength and rigidity due to its dense fiber composition, making it ideal for heavy-duty packaging and structural applications. Honeycomb board provides excellent strength-to-weight ratio by utilizing a hexagonal core design that distributes loads efficiently while minimizing material usage. In terms of structural strength, solid board excels in resistance to crushing, whereas honeycomb board offers superior impact absorption and flexibility under dynamic stress.

Weight Differences and Implications

Solid board typically weighs more due to its dense, compact structure, providing superior strength and rigidity compared to honeycomb board. Honeycomb board features a lightweight core design with hexagonal cells, significantly reducing weight while maintaining good load distribution, ideal for applications requiring weight savings. The weight difference impacts shipping costs and handling ease, with honeycomb board offering enhanced portability but potentially less impact resistance than solid board.

Cost Efficiency Analysis

Solid board offers higher durability and stiffness but comes at a premium cost due to denser materials and heavier weight. Honeycomb board provides superior cost efficiency with its lightweight structure, reducing material usage and transportation expenses while maintaining adequate strength for many packaging needs. Choosing between solid and honeycomb board involves analyzing specific application requirements against budget constraints and logistics considerations.

Environmental Impact and Sustainability

Solid board typically has a higher environmental impact due to its production process requiring more raw materials and energy compared to honeycomb board, which utilizes a core structure reducing material use. Honeycomb board is generally more sustainable, offering enhanced recyclability and lower carbon footprint through its lightweight design and efficient resource usage. Both materials can be recycled, but honeycomb board's reduced weight contributes to lower transportation emissions and less waste in landfills.

Ideal Applications for Each Board Type

Solid board excels in packaging heavy or fragile items due to its dense, sturdy structure providing superior strength and protection. Honeycomb board, characterized by its lightweight design and excellent shock absorption, is ideal for large-scale shipping, exhibition displays, and furniture components. Choosing the right board depends on balancing durability requirements and weight constraints in specific industrial and commercial applications.

Choosing the Right Board for Your Needs

Solid board offers superior strength and durability, making it ideal for heavy-duty packaging and long-term storage. Honeycomb board provides excellent cushioning and lightweight properties, suitable for protection during shipping and cost-effective projects. Selecting the right board depends on balancing the need for structural support against weight and budget constraints.

Solid Board vs Honeycomb Board Infographic

materialdif.com

materialdif.com