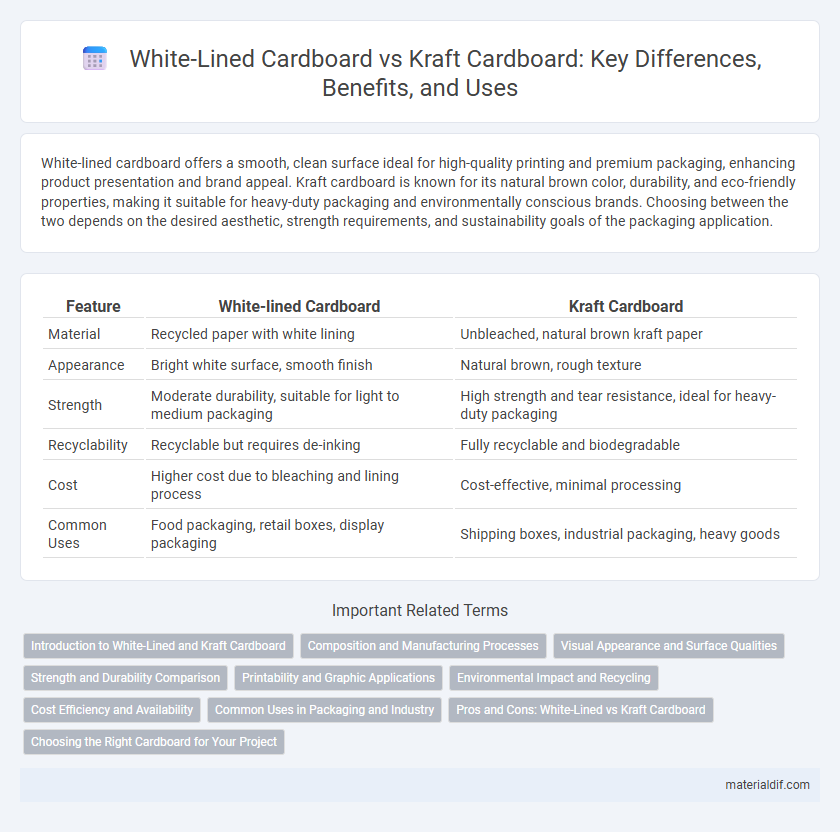

White-lined cardboard offers a smooth, clean surface ideal for high-quality printing and premium packaging, enhancing product presentation and brand appeal. Kraft cardboard is known for its natural brown color, durability, and eco-friendly properties, making it suitable for heavy-duty packaging and environmentally conscious brands. Choosing between the two depends on the desired aesthetic, strength requirements, and sustainability goals of the packaging application.

Table of Comparison

| Feature | White-lined Cardboard | Kraft Cardboard |

|---|---|---|

| Material | Recycled paper with white lining | Unbleached, natural brown kraft paper |

| Appearance | Bright white surface, smooth finish | Natural brown, rough texture |

| Strength | Moderate durability, suitable for light to medium packaging | High strength and tear resistance, ideal for heavy-duty packaging |

| Recyclability | Recyclable but requires de-inking | Fully recyclable and biodegradable |

| Cost | Higher cost due to bleaching and lining process | Cost-effective, minimal processing |

| Common Uses | Food packaging, retail boxes, display packaging | Shipping boxes, industrial packaging, heavy goods |

Introduction to White-Lined and Kraft Cardboard

White-lined cardboard features a clay-coated white surface that enhances print quality and aesthetics, making it ideal for high-end packaging and retail displays. Kraft cardboard is made from unbleached, natural brown fibers, offering superior durability and eco-friendliness for shipping and heavy-duty packaging applications. Both types serve specific industry needs, with white-lined prioritizing appearance and kraft emphasizing strength and sustainability.

Composition and Manufacturing Processes

White-lined cardboard consists of multiple layers of bleached and unbleached paper fibers, with a smooth white top layer for enhanced printability and aesthetics, produced via a coating process on recycled or virgin fibers. Kraft cardboard is made from unbleached pulp, primarily derived from softwood trees, employing the kraft process that emphasizes strength and durability through chemical pulping. The manufacturing of white-lined cardboard involves layering and coating to achieve a clean surface, whereas kraft cardboard manufacturing focuses on maintaining fiber toughness and natural brown coloration without additional coatings.

Visual Appearance and Surface Qualities

White-lined cardboard features a smooth, bright white surface ideal for high-quality printing and vibrant graphics, enhancing brand appeal through sharp visual presentation. Kraft cardboard has a natural brown, textured surface that provides a rustic and eco-friendly appearance, favored for its sturdiness and sustainable image. The choice between the two depends on the desired aesthetic impact and printing requirements for packaging or promotional materials.

Strength and Durability Comparison

White-lined cardboard offers a smoother surface ideal for printing, but Kraft cardboard surpasses it in strength and durability due to its high-quality virgin wood fibers and minimal processing. Kraft cardboard's natural brown color results from less bleaching, preserving fiber integrity and making it more resistant to tears, punctures, and moisture. For heavy-duty packaging requiring robust protection, Kraft cardboard is the preferred choice, whereas white-lined cardboard suits applications prioritizing aesthetics over maximum strength.

Printability and Graphic Applications

White-lined cardboard offers superior printability due to its smooth, bleached surface that enhances color vibrancy and sharpness, making it ideal for high-quality graphic applications. Kraft cardboard, with its natural brown tone and rough texture, absorbs ink differently, producing a more rustic appearance but limiting the detail and brightness of printed graphics. For packaging requiring premium visual impact, white-lined cardboard is preferred, whereas kraft cardboard suits eco-friendly designs emphasizing durability over intricate graphics.

Environmental Impact and Recycling

White-lined cardboard often contains bleached fibers and coating layers, which can complicate the recycling process and increase environmental impact due to chemical treatments. Kraft cardboard, made from unbleached pulp, is more environmentally friendly with higher recyclability and lower energy consumption during production. Choosing kraft cardboard supports sustainable packaging by reducing waste and promoting closed-loop recycling systems.

Cost Efficiency and Availability

White-lined cardboard offers superior cost efficiency due to its lighter weight and lower production expenses compared to Kraft cardboard. Kraft cardboard, made from unbleached wood fibers, is more readily available and durable, often preferred for heavy-duty packaging needs. Companies balancing budget and availability often choose white-lined cardboard for lighter products, while Kraft cardboard remains the go-to for high-strength applications.

Common Uses in Packaging and Industry

White-lined cardboard is commonly used in packaging for consumer goods such as cereal boxes, frozen food containers, and retail packaging due to its smooth, printable surface that enhances brand presentation. Kraft cardboard is favored in industrial applications like shipping boxes, heavy-duty packaging, and protective packaging because of its natural strength, durability, and resistance to tearing. Both materials serve distinct roles: white-lined cardboard prioritizes visual appeal and print quality, while kraft cardboard emphasizes structural integrity and cost-effectiveness.

Pros and Cons: White-Lined vs Kraft Cardboard

White-lined cardboard offers a smooth, printable surface ideal for high-quality graphics and branding, but tends to be less durable and more expensive than kraft cardboard. Kraft cardboard excels in strength and environmental sustainability due to its recycled content and natural fibers, though it lacks the premium appearance of white-lined options. Choosing between white-lined and kraft cardboard depends on the need for aesthetics versus durability and eco-friendliness in packaging applications.

Choosing the Right Cardboard for Your Project

White-lined cardboard offers a smooth, printable surface ideal for high-quality graphics and branding, making it perfect for retail packaging and presentation boxes. Kraft cardboard provides superior strength and durability with a natural brown finish, suited for heavy-duty shipping and eco-friendly packaging solutions. Selecting the right cardboard depends on your project's need for visual appeal versus structural integrity and environmental considerations.

White-lined cardboard vs Kraft cardboard Infographic

materialdif.com

materialdif.com