Grayboard and Kraft cardboard differ primarily in composition and strength, with grayboard made from recycled paper and featuring a smooth, rigid surface ideal for packaging and backing. Kraft cardboard is produced from virgin wood pulp, offering superior durability and moisture resistance, making it suitable for heavy-duty shipping and industrial uses. Choosing between grayboard and Kraft cardboard depends on the balance between cost-effectiveness and the specific structural requirements of the packaging application.

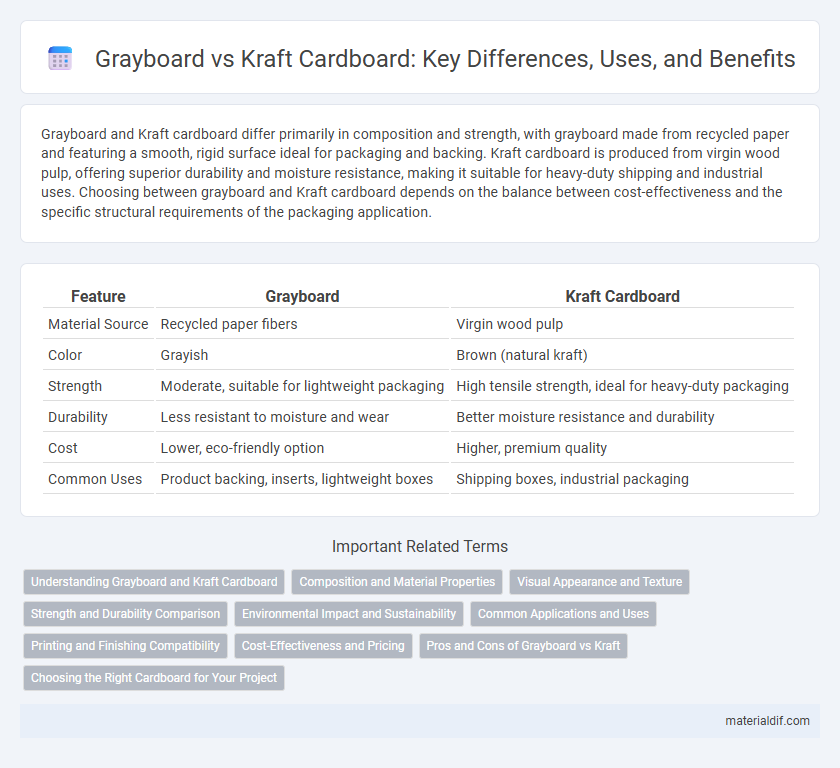

Table of Comparison

| Feature | Grayboard | Kraft Cardboard |

|---|---|---|

| Material Source | Recycled paper fibers | Virgin wood pulp |

| Color | Grayish | Brown (natural kraft) |

| Strength | Moderate, suitable for lightweight packaging | High tensile strength, ideal for heavy-duty packaging |

| Durability | Less resistant to moisture and wear | Better moisture resistance and durability |

| Cost | Lower, eco-friendly option | Higher, premium quality |

| Common Uses | Product backing, inserts, lightweight boxes | Shipping boxes, industrial packaging |

Understanding Grayboard and Kraft Cardboard

Grayboard, a dense and rigid paperboard made from recycled fibers, offers superior strength and durability, making it ideal for packaging heavy or high-end products. Kraft cardboard, produced from unbleached kraft pulp, features a natural brown color and high tear resistance, favored for eco-friendly packaging and sturdy shipping boxes. Understanding the distinct fiber composition and manufacturing processes of grayboard and kraft cardboard is essential for selecting the right material based on weight capacity, surface finish, and environmental impact.

Composition and Material Properties

Grayboard is composed primarily of recycled paper fibers, offering a dense and stiff structure with a matte, grayish surface that enhances rigidity and durability. Kraft cardboard is made from virgin wood pulp using the kraft process, resulting in a stronger, more flexible material with a natural brown color and high tear resistance. The chemical treatment in kraft cardboard imparts superior moisture resistance, making it ideal for heavy-duty packaging compared to the more eco-friendly but less robust grayboard.

Visual Appearance and Texture

Grayboard typically features a dull, matte surface with a uniform gray color, offering a smooth but slightly rough texture ideal for structural strength rather than aesthetics. Kraft cardboard has a natural brown, earthy tone with a coarser texture due to its unbleached wood fibers, providing a rustic and organic appearance. The visual appeal of Kraft is preferred for eco-friendly packaging, while Grayboard is chosen for applications requiring a clean, solid backing.

Strength and Durability Comparison

Grayboard offers superior strength and rigidity due to its dense composition made from recycled fibers, making it ideal for heavy-duty packaging. Kraft cardboard, produced from virgin wood pulp, provides enhanced durability and resistance to tearing, suitable for products requiring strong protection. Both materials excel in different aspects of strength, with grayboard favored for structural integrity and kraft cardboard optimized for impact resistance and flexibility.

Environmental Impact and Sustainability

Grayboard is primarily made from recycled paper and has a lower environmental footprint due to its high recycled content and energy-efficient production processes. Kraft cardboard, derived from virgin wood fibers through the kraft process, tends to be more biodegradable but involves higher resource consumption and deforestation risks. Choosing grayboard supports circular economy principles by diverting paper waste from landfills, while kraft cardboard excels in compostability and fiber strength for reusable packaging solutions.

Common Applications and Uses

Grayboard is commonly used in packaging for rigid boxes, bookbinding, and backing for notepads, thanks to its dense, sturdy composition. Kraft cardboard, with its high strength and moisture resistance, is ideal for shipping boxes, grocery bags, and heavy-duty packaging. Both materials serve important roles in packaging industries but differ in durability and finish suited to specific applications.

Printing and Finishing Compatibility

Grayboard offers a smooth, dense surface that enhances high-quality printing and allows for detailed finishes, making it ideal for premium packaging. Kraft cardboard provides excellent strength and natural brown tones but may require additional surface treatment for optimal printing results. Both materials support various finishing options such as lamination and embossing, with grayboard typically delivering a more refined aesthetic.

Cost-Effectiveness and Pricing

Grayboard offers a more cost-effective solution for packaging applications requiring stiffness and recyclability, priced lower due to its production from recycled fibers. Kraft cardboard, made from virgin wood fibers, commands a higher price reflecting its superior durability, moisture resistance, and strength. Businesses prioritizing budget-friendly, eco-friendly options often select grayboard, while those needing premium structural performance invest in kraft cardboard despite the higher cost.

Pros and Cons of Grayboard vs Kraft

Grayboard offers superior stiffness and excellent surface smoothness, making it ideal for packaging that requires high durability and a premium finish; however, it is generally heavier and less flexible than kraft cardboard. Kraft cardboard provides better tear resistance and flexibility due to its natural wood fiber content, making it more suitable for lightweight packaging and eco-friendly applications, though it may lack the rigidity needed for heavy-duty protection. Both materials balance cost and performance differently, with grayboard favored for structural strength and kraft cardboard preferred for versatility and recyclability.

Choosing the Right Cardboard for Your Project

Grayboard offers a dense, rigid structure ideal for packaging and craft projects requiring high durability and excellent printability, while Kraft cardboard provides flexibility and strength with its natural brown fibers, making it suitable for shipping boxes and eco-friendly packaging. Consider project requirements such as weight capacity, surface finish, and environmental impact when choosing between Grayboard and Kraft cardboard. Selecting the right cardboard type ensures optimal performance, cost-efficiency, and sustainability for your specific application.

Grayboard vs Kraft Cardboard Infographic

materialdif.com

materialdif.com