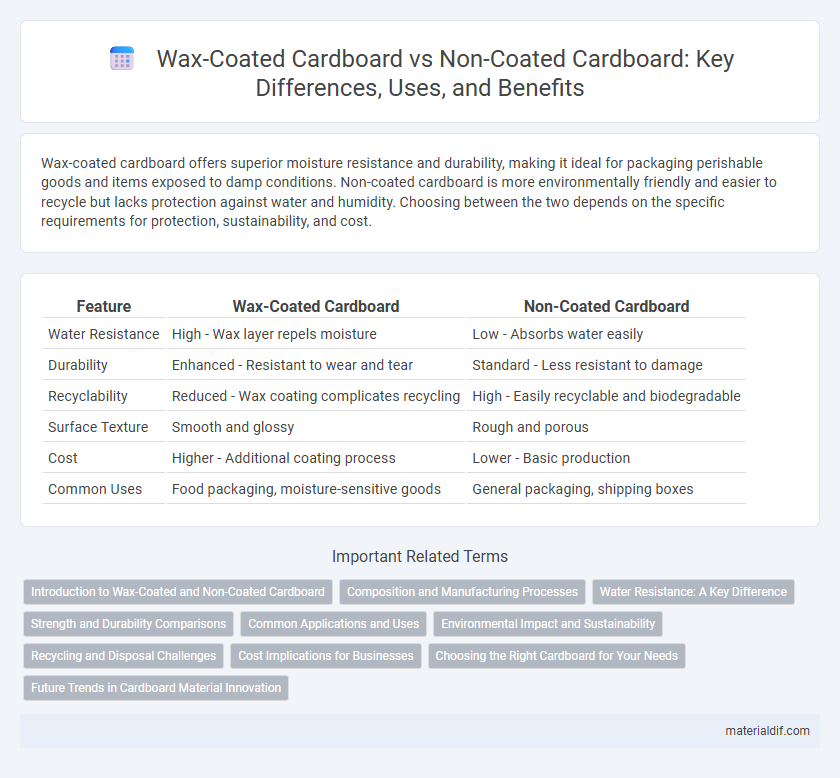

Wax-coated cardboard offers superior moisture resistance and durability, making it ideal for packaging perishable goods and items exposed to damp conditions. Non-coated cardboard is more environmentally friendly and easier to recycle but lacks protection against water and humidity. Choosing between the two depends on the specific requirements for protection, sustainability, and cost.

Table of Comparison

| Feature | Wax-Coated Cardboard | Non-Coated Cardboard |

|---|---|---|

| Water Resistance | High - Wax layer repels moisture | Low - Absorbs water easily |

| Durability | Enhanced - Resistant to wear and tear | Standard - Less resistant to damage |

| Recyclability | Reduced - Wax coating complicates recycling | High - Easily recyclable and biodegradable |

| Surface Texture | Smooth and glossy | Rough and porous |

| Cost | Higher - Additional coating process | Lower - Basic production |

| Common Uses | Food packaging, moisture-sensitive goods | General packaging, shipping boxes |

Introduction to Wax-Coated and Non-Coated Cardboard

Wax-coated cardboard features a thin layer of wax applied to its surface, providing water resistance and enhanced durability for packaging applications requiring moisture protection. Non-coated cardboard lacks this protective wax layer, making it more absorbent and suitable for dry goods or products not exposed to humidity. Selecting between wax-coated and non-coated cardboard depends on the specific needs of storage, shipment, and environmental exposure.

Composition and Manufacturing Processes

Wax-coated cardboard consists of cellulose fibers infused with a thin layer of paraffin or synthetic wax applied during manufacturing to enhance water resistance and durability. Non-coated cardboard is primarily made from untreated cellulose fibers, formed by pressing and drying wood pulp without additional surface treatments. The manufacturing process for wax-coated cardboard includes an extra step of dipping or spraying the cardboard in molten wax, while non-coated cardboard follows a simpler pulping, forming, and drying sequence.

Water Resistance: A Key Difference

Wax-coated cardboard offers superior water resistance compared to non-coated cardboard, making it ideal for packaging products exposed to moisture or humidity. The wax layer creates a moisture barrier that prevents water absorption, preserving structural integrity and reducing the risk of sogginess or weakening. Non-coated cardboard, lacking this protective layer, absorbs water more readily, leading to faster degradation and compromised durability in wet conditions.

Strength and Durability Comparisons

Wax-coated cardboard offers enhanced water resistance and increased durability compared to non-coated cardboard, making it ideal for packaging products exposed to moisture. Non-coated cardboard, while typically lighter and more environmentally friendly, tends to absorb moisture and loses structural integrity more quickly under wet or humid conditions. Strength-wise, wax-coated cardboard maintains its rigidity and resists weakening, whereas non-coated cardboard may become soft and prone to bending or tearing when damp.

Common Applications and Uses

Wax-coated cardboard is widely used in food packaging, especially for products requiring moisture resistance like fresh produce, seafood, and baked goods, ensuring durability and protecting contents from contamination. Non-coated cardboard is commonly utilized for shipping boxes, product displays, and storage solutions due to its breathability and cost-effectiveness. Both types serve crucial roles in packaging, with wax-coated cardboard excelling in moisture-sensitive applications and non-coated cardboard preferred for general-purpose packaging and shipping.

Environmental Impact and Sustainability

Wax-coated cardboard is less biodegradable and more challenging to recycle due to its moisture-resistant wax layer, contributing to increased environmental waste. Non-coated cardboard offers greater sustainability benefits, as it decomposes naturally and is widely accepted in standard recycling processes. Choosing non-coated cardboard supports eco-friendly packaging practices and reduces landfill accumulation.

Recycling and Disposal Challenges

Wax-coated cardboard presents significant recycling challenges due to the wax layer hindering the pulping process, often requiring specialized facilities or alternative recycling methods. Non-coated cardboard is more readily recyclable as it can be processed with standard paper recycling streams without contamination. Disposal of wax-coated cardboard in landfills can lead to longer decomposition times and potential environmental harm compared to biodegradable non-coated cardboard.

Cost Implications for Businesses

Wax-coated cardboard typically incurs higher production and disposal costs due to the added materials and specialized recycling requirements, impacting businesses' overall packaging expenses. Non-coated cardboard offers a more cost-effective solution with lower manufacturing costs and simpler recycling processes, reducing waste management fees. Choosing between these options depends on balancing upfront packaging investments with long-term sustainability and operational costs.

Choosing the Right Cardboard for Your Needs

Wax-coated cardboard offers enhanced moisture resistance and durability, making it ideal for packaging perishable goods or items exposed to humidity. Non-coated cardboard, being more cost-effective and environmentally friendly, suits dry goods and applications where recyclability is a priority. Selecting the right cardboard depends on balancing moisture protection requirements with budget considerations and sustainability goals.

Future Trends in Cardboard Material Innovation

Wax-coated cardboard enhances moisture resistance and durability, making it ideal for food packaging and outdoor uses, while non-coated cardboard remains favored for recyclability and eco-friendliness. Emerging trends focus on developing biodegradable wax alternatives and improving coating technologies to balance sustainability with performance. Innovations in bio-based coatings and smart materials are poised to redefine cardboard's environmental impact and functional versatility.

Wax-Coated Cardboard vs Non-Coated Cardboard Infographic

materialdif.com

materialdif.com