SBS (Solid Bleached Sulfate) is a high-quality, pure cellulose paperboard known for its bright white surface, excellent printability, and superior strength, making it ideal for premium packaging. FBB (Folding Box Board) combines bleached chemical pulp with mechanical pulp, resulting in a cost-effective, lightweight material with good stiffness and versatility for various folding carton applications. Choosing between SBS and FBB depends on the desired finish, strength requirements, and budget constraints in packaging production.

Table of Comparison

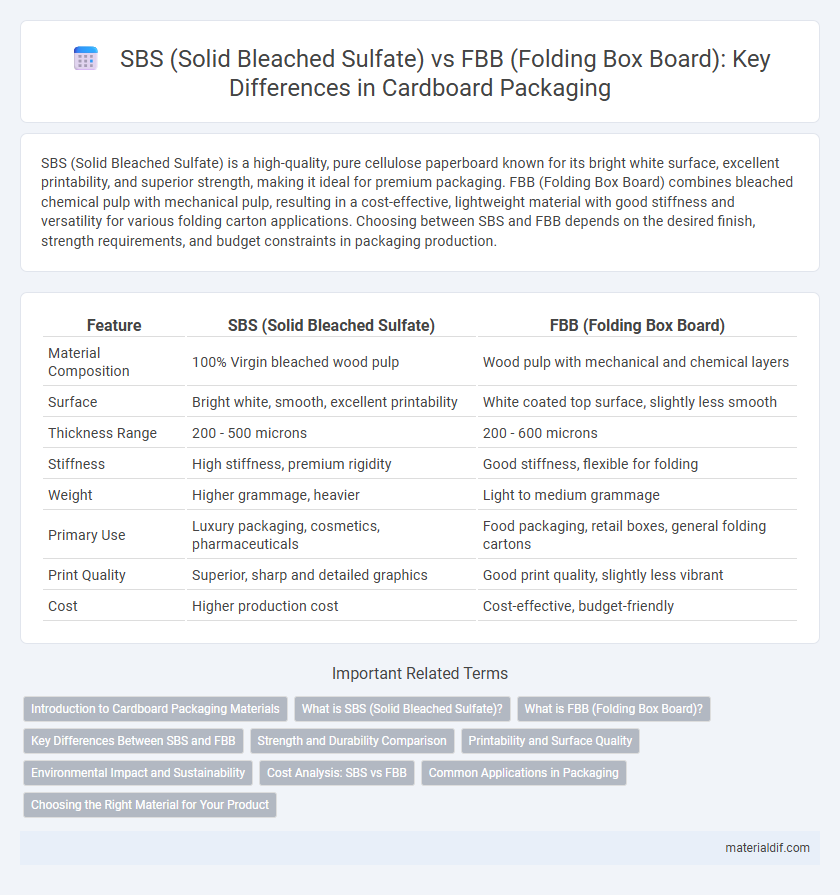

| Feature | SBS (Solid Bleached Sulfate) | FBB (Folding Box Board) |

|---|---|---|

| Material Composition | 100% Virgin bleached wood pulp | Wood pulp with mechanical and chemical layers |

| Surface | Bright white, smooth, excellent printability | White coated top surface, slightly less smooth |

| Thickness Range | 200 - 500 microns | 200 - 600 microns |

| Stiffness | High stiffness, premium rigidity | Good stiffness, flexible for folding |

| Weight | Higher grammage, heavier | Light to medium grammage |

| Primary Use | Luxury packaging, cosmetics, pharmaceuticals | Food packaging, retail boxes, general folding cartons |

| Print Quality | Superior, sharp and detailed graphics | Good print quality, slightly less vibrant |

| Cost | Higher production cost | Cost-effective, budget-friendly |

Introduction to Cardboard Packaging Materials

SBS (Solid Bleached Sulfate) and FBB (Folding Box Board) are premium cardboard packaging materials widely used for high-quality product packaging due to their durability and printability. SBS is made from bleached virgin wood pulp, offering a smooth, bright white surface ideal for high-end graphics and food-safe applications. FBB combines bleached chemical pulp with mechanical pulp layers, providing excellent stiffness and cost efficiency, making it suitable for cosmetics, pharmaceuticals, and consumer goods packaging.

What is SBS (Solid Bleached Sulfate)?

SBS (Solid Bleached Sulfate) is a high-quality, virgin fiber-based paperboard known for its purity, strength, and smooth surface, making it ideal for premium packaging applications. Manufactured through a chemical pulping process and bleached to achieve a bright white appearance, SBS provides excellent printability and a clean, attractive finish. Its durability and resistance to moisture make SBS a preferred choice for cosmetics, pharmaceuticals, and food packaging that demand hygiene and visual appeal.

What is FBB (Folding Box Board)?

Folding Box Board (FBB) is a type of high-quality paperboard primarily used for premium packaging applications such as cosmetics, pharmaceuticals, and food products. It consists of multiple layers including a bleached chemical pulp top layer, mechanical pulp middle layers, and a bleached chemical pulp back layer, providing excellent stiffness, durability, and printability. FBB offers superior surface smoothness and brightness compared to Solid Bleached Sulfate (SBS), making it ideal for high-end folding cartons requiring a premium finish.

Key Differences Between SBS and FBB

SBS (Solid Bleached Sulfate) is a premium, pure bleached wood pulp board known for its high whiteness, smooth surface, and excellent printability, making it ideal for luxury packaging and food-grade applications. FBB (Folding Box Board) consists of multiple layers including mechanical pulp, offering higher stiffness, superior bulk, and better cost-efficiency, commonly used in general packaging and retail boxes. The key differences lie in SBS's superior purity and surface quality versus FBB's enhanced rigidity and economical advantages.

Strength and Durability Comparison

SBS (Solid Bleached Sulfate) offers superior strength and moisture resistance due to its fully bleached chemical pulp composition, making it ideal for packaging requiring high durability. FBB (Folding Box Board) combines mechanical and chemical pulp layers, providing good stiffness and surface smoothness but generally lower tensile strength and moisture resistance compared to SBS. For applications demanding robust structural integrity and resistance to wear, SBS is preferred, while FBB suits lighter packaging needs with moderate strength.

Printability and Surface Quality

SBS (Solid Bleached Sulfate) offers superior printability due to its consistently smooth, bright white surface, making it ideal for high-end packaging with sharp, vibrant graphics. FBB (Folding Box Board) provides a slightly more textured surface, resulting in good printability but with less color vibrancy and detail compared to SBS. The enhanced surface quality of SBS supports advanced finishes such as UV coating and foil stamping, enhancing the visual appeal and tactile experience.

Environmental Impact and Sustainability

SBS (Solid Bleached Sulfate) and FBB (Folding Box Board) differ significantly in environmental impact, as SBS is made from pure chemical pulp with high bleaching processes, leading to higher energy consumption and chemical use. FBB incorporates recycled fibers and mechanical pulp alongside chemical pulp, resulting in lower carbon footprint and better sustainability credentials due to reduced resource intensity. Sustainable packaging initiatives prefer FBB for its enhanced recyclability, biodegradability, and reduced environmental burden compared to the more resource-intensive SBS.

Cost Analysis: SBS vs FBB

Solid Bleached Sulfate (SBS) typically incurs higher material and production costs compared to Folding Box Board (FBB) due to its superior purity, brightness, and strength characteristics. SBS is preferred for premium packaging requiring excellent printability and food safety compliance, influencing its cost-effectiveness depending on application demands. FBB offers a more economical alternative with adequate stiffness and print quality, making it suitable for a broader range of consumer goods packaging where cost efficiency is critical.

Common Applications in Packaging

SBS (Solid Bleached Sulfate) is widely used in premium packaging for cosmetics, pharmaceuticals, and food products due to its high brightness, excellent printability, and moisture resistance. FBB (Folding Box Board) is commonly employed in packaging for cereals, frozen foods, and retail boxes because of its stiffness, good folding properties, and cost-effectiveness. Both materials offer strong structural integrity but are chosen based on specific application needs like print finish quality and product protection.

Choosing the Right Material for Your Product

SBS (Solid Bleached Sulfate) offers a smooth, high-quality white surface ideal for premium packaging with vibrant printing and excellent rigidity, making it suitable for luxury goods and cosmetics. FBB (Folding Box Board), featuring multiple layers including mechanical pulp, provides superior stiffness and cost-effectiveness, often used for food packaging and pharmaceuticals requiring durability and protection. Selecting between SBS and FBB depends on your product's visual appeal needs, strength requirements, and budget constraints to ensure optimal packaging performance.

SBS (Solid Bleached Sulfate) vs FBB (Folding Box Board) Infographic

materialdif.com

materialdif.com