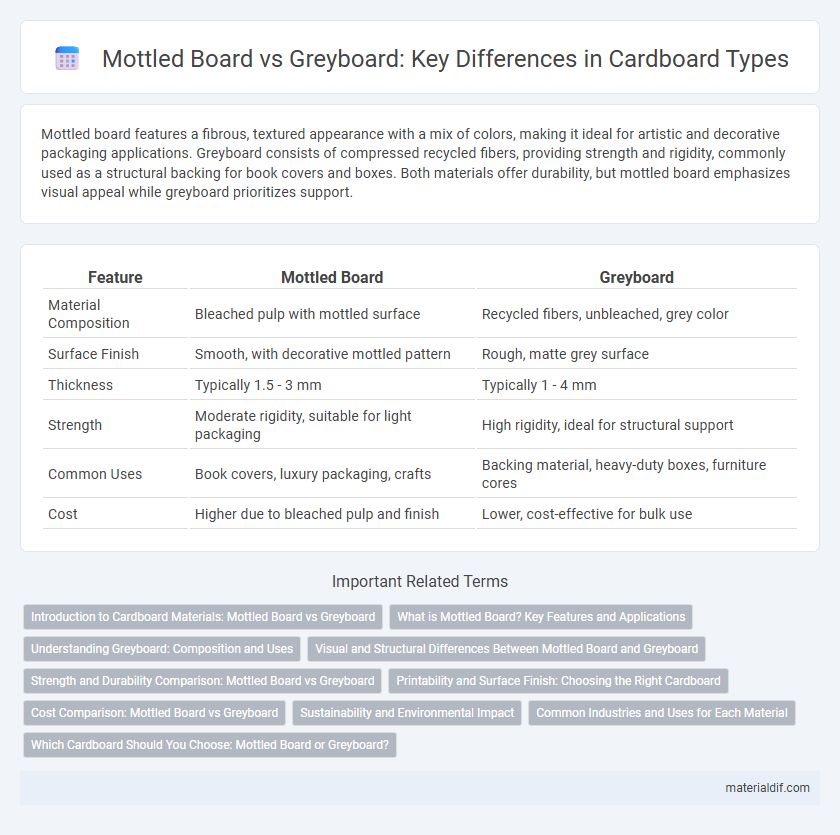

Mottled board features a fibrous, textured appearance with a mix of colors, making it ideal for artistic and decorative packaging applications. Greyboard consists of compressed recycled fibers, providing strength and rigidity, commonly used as a structural backing for book covers and boxes. Both materials offer durability, but mottled board emphasizes visual appeal while greyboard prioritizes support.

Table of Comparison

| Feature | Mottled Board | Greyboard |

|---|---|---|

| Material Composition | Bleached pulp with mottled surface | Recycled fibers, unbleached, grey color |

| Surface Finish | Smooth, with decorative mottled pattern | Rough, matte grey surface |

| Thickness | Typically 1.5 - 3 mm | Typically 1 - 4 mm |

| Strength | Moderate rigidity, suitable for light packaging | High rigidity, ideal for structural support |

| Common Uses | Book covers, luxury packaging, crafts | Backing material, heavy-duty boxes, furniture cores |

| Cost | Higher due to bleached pulp and finish | Lower, cost-effective for bulk use |

Introduction to Cardboard Materials: Mottled Board vs Greyboard

Mottled board consists of recycled fibers with a mixed-color appearance and a smooth clay-coated surface, often used for packaging and book covers due to its durability and printability. Greyboard is made from compressed recycled paper, displaying a uniform grey color and higher rigidity, making it ideal for structural applications like backing and rigid boxes. Both materials offer eco-friendly solutions with distinct textures and strengths tailored to different cardboard products.

What is Mottled Board? Key Features and Applications

Mottled board is a type of cardboard characterized by its rigid, dense fiber composition with a speckled or mottled surface pattern, offering enhanced durability and a premium tactile feel compared to standard greyboard. Key features include its high strength, resistance to crushing, and smooth finish that makes it ideal for luxury packaging, bookbinding, and high-end presentation boxes. Common applications leverage its structural integrity and aesthetic appeal to protect delicate items while providing an attractive, professional appearance.

Understanding Greyboard: Composition and Uses

Greyboard consists of recycled paper fibers compressed into thick, rigid sheets, offering a denser structure compared to mottled board. Its uniform grey color results from the high content of recycled material and absence of surface coatings, enhancing durability for bookbinding, packaging, and backing applications. Greyboard's strength and rigidity make it ideal for protecting delicate items and providing structural support in various crafting and industrial uses.

Visual and Structural Differences Between Mottled Board and Greyboard

Mottled Board features a distinctive mottled or speckled surface texture, providing a visually dynamic and aesthetically appealing finish, while Greyboard exhibits a more uniform, smooth, and matte appearance suited for base structural applications. Structurally, Mottled Board is typically thinner and slightly more flexible, making it ideal for luxury packaging and presentation boxes, whereas Greyboard is denser, thicker, and sturdier, designed to offer maximum rigidity and support in heavy-duty bookbinding and industrial uses. The color contrast is also notable: Mottled Board often has a decorative patterned surface, whereas Greyboard retains a consistent grey tone throughout the core and surface layers.

Strength and Durability Comparison: Mottled Board vs Greyboard

Mottled board offers superior strength and durability compared to greyboard due to its multi-layered construction and high-density fiber composition, making it ideal for heavy-duty packaging and bookbinding applications. Greyboard, while cost-effective and moderately sturdy, lacks the robust structural integrity of mottled board and tends to warp or deteriorate faster under stress. Choosing mottled board ensures enhanced resilience and longer lifespan for products requiring rigid support and impact resistance.

Printability and Surface Finish: Choosing the Right Cardboard

Mottled board offers a smoother, more uniform surface finish that enhances print quality and color vibrancy, making it ideal for high-end packaging with detailed graphic designs. Greyboard features a rougher texture and uneven color distribution, which may affect the sharpness and clarity of printed materials, but provides excellent rigidity and strength for structural support. Selecting between mottled board and greyboard depends on prioritizing superior printability and surface aesthetics versus durability and cost-effectiveness in cardboard applications.

Cost Comparison: Mottled Board vs Greyboard

Mottled board generally costs more than greyboard due to its higher manufacturing quality and smoother surface finish, which enhances printability and aesthetic appeal. Greyboard, being a recycled material, offers a more budget-friendly option ideal for packaging and structural applications where appearance is less critical. The price difference typically reflects the use case, with mottled board favored for premium packaging and greyboard for cost-effective, sturdy solutions.

Sustainability and Environmental Impact

Mottled board and greyboard differ significantly in sustainability, with mottled board typically produced from recycled fibers but featuring lower recyclability due to mixed materials, whereas greyboard is made from 100% recycled cardboard and boasts higher recyclability and biodegradability. The production of greyboard involves fewer chemicals and less energy consumption, contributing to a reduced carbon footprint compared to mottled board manufacturing. Choosing greyboard supports circular economy principles by enhancing resource efficiency and minimizing landfill waste, making it a more environmentally responsible packaging option.

Common Industries and Uses for Each Material

Mottled board, often used in packaging for luxury goods, cosmetics, and electronics, offers a high-quality appearance with a textured finish that enhances brand presentation. Greyboard is widely utilized in bookbinding, furniture backing, and industrial packaging due to its sturdy composition and cost-effectiveness. Both materials serve key roles in industries where durability and aesthetic appeal are essential, with mottled board favored for visual impact and greyboard chosen for structural support.

Which Cardboard Should You Choose: Mottled Board or Greyboard?

Mottled board features a smooth, bleached surface ideal for high-quality printing and packaging, while greyboard offers sturdy, recycled fiber content suited for structural support in boxes and bookbinding. Choosing between mottled board and greyboard depends on whether the priority is aesthetic appeal or durability, with mottled board excelling in visual presentation and greyboard providing greater strength and eco-friendliness. For premium packaging requiring a clean finish, mottled board is preferable, whereas greyboard serves well in applications demanding robustness and cost-effectiveness.

Mottled Board vs Greyboard Infographic

materialdif.com

materialdif.com