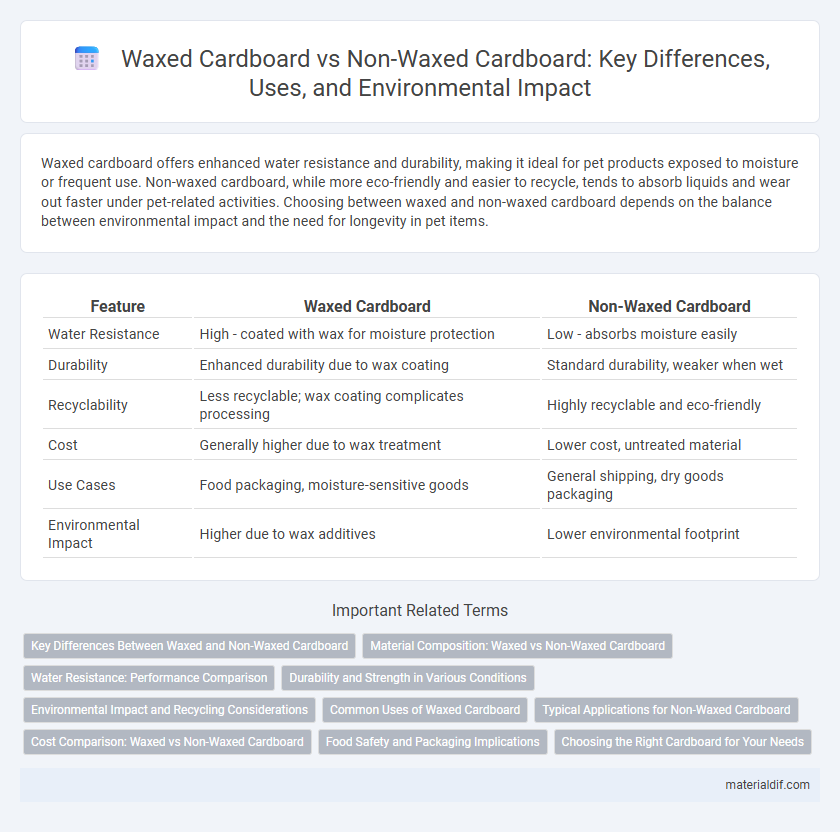

Waxed cardboard offers enhanced water resistance and durability, making it ideal for pet products exposed to moisture or frequent use. Non-waxed cardboard, while more eco-friendly and easier to recycle, tends to absorb liquids and wear out faster under pet-related activities. Choosing between waxed and non-waxed cardboard depends on the balance between environmental impact and the need for longevity in pet items.

Table of Comparison

| Feature | Waxed Cardboard | Non-Waxed Cardboard |

|---|---|---|

| Water Resistance | High - coated with wax for moisture protection | Low - absorbs moisture easily |

| Durability | Enhanced durability due to wax coating | Standard durability, weaker when wet |

| Recyclability | Less recyclable; wax coating complicates processing | Highly recyclable and eco-friendly |

| Cost | Generally higher due to wax treatment | Lower cost, untreated material |

| Use Cases | Food packaging, moisture-sensitive goods | General shipping, dry goods packaging |

| Environmental Impact | Higher due to wax additives | Lower environmental footprint |

Key Differences Between Waxed and Non-Waxed Cardboard

Waxed cardboard is coated with a layer of wax that provides water resistance and increased durability, making it ideal for packaging moist or heavy items. Non-waxed cardboard lacks this protective coating, resulting in lower moisture resistance and reduced suitability for wet environments. The key differences lie in moisture protection, durability, and application suitability, with waxed cardboard preferred for preservation and non-waxed for general-purpose packaging.

Material Composition: Waxed vs Non-Waxed Cardboard

Waxed cardboard features a thin layer of paraffin or polyethylene wax coating that enhances moisture resistance and durability, making it ideal for packaging items prone to damp conditions. Non-waxed cardboard consists purely of cellulose fibers without any surface treatment, offering higher recyclability but less protection against water and grease. The material composition differences significantly impact performance, with waxed cardboard providing superior barrier properties while non-waxed cardboard emphasizes environmental sustainability.

Water Resistance: Performance Comparison

Waxed cardboard offers superior water resistance due to a coating of paraffin or natural wax that creates a moisture barrier, preventing absorption and structural damage. Non-waxed cardboard lacks this protective layer, resulting in rapid water absorption, weakening, and eventual disintegration upon exposure to moisture. Performance tests consistently show waxed cardboard maintaining integrity in wet conditions, making it ideal for packaging items requiring moisture protection.

Durability and Strength in Various Conditions

Waxed cardboard offers enhanced durability and moisture resistance due to its protective coating, making it ideal for packaging items exposed to damp or humid environments. Non-waxed cardboard lacks this coating, resulting in lower strength and increased susceptibility to water damage, which limits its use to dry conditions. The wax layer adds rigidity and prevents weakening of the fiber structure, ensuring better performance in varied environmental stresses.

Environmental Impact and Recycling Considerations

Waxed cardboard, coated with a thin layer of paraffin or soy-based wax, offers moisture resistance but complicates recycling due to contamination of paper fibers, often resulting in landfill disposal and increased environmental burden. Non-waxed cardboard, primarily composed of untreated paper fibers, is more widely accepted in recycling streams, promoting efficient fiber recovery and reducing waste in landfills. Choosing non-waxed cardboard supports sustainable packaging initiatives by minimizing environmental impact and enhancing circular economy practices in paper recycling systems.

Common Uses of Waxed Cardboard

Waxed cardboard is commonly used in packaging fresh produce, seafood, and meat due to its moisture-resistant properties that prevent leakage and maintain product freshness. It also serves effectively in industrial applications where water repellency and durability are essential, such as in shipping containers and agricultural trays. The wax coating enhances protection against humidity and contamination, making waxed cardboard a preferred choice in food transportation and storage.

Typical Applications for Non-Waxed Cardboard

Non-waxed cardboard is commonly used for packaging dry goods, shipping boxes, and product displays due to its breathability and cost-effectiveness. It is ideal for applications requiring recyclability and environmental sustainability, such as food trays, cereal boxes, and retail packaging. This type of cardboard offers strong structural support without a moisture-resistant coating, making it suitable for items that do not require water protection.

Cost Comparison: Waxed vs Non-Waxed Cardboard

Waxed cardboard generally incurs higher production costs due to the additional waxing process and materials, which enhance moisture resistance and durability. Non-waxed cardboard is more cost-effective, as it lacks the extra coating, making it suitable for dry or less demanding environments. Choosing between waxed and non-waxed cardboard depends on budget constraints and specific usage requirements, with waxed cardboard offering superior protection at a premium price.

Food Safety and Packaging Implications

Waxed cardboard provides a moisture-resistant barrier that enhances food safety by preventing leaks and contamination, making it ideal for packaging greasy or wet foods. Non-waxed cardboard, while more eco-friendly and recyclable, lacks water resistance, increasing the risk of sogginess and microbial growth in food packaging. Choosing waxed cardboard ensures better preservation and hygiene, whereas non-waxed cardboard requires additional lining or treatment for safe food packaging.

Choosing the Right Cardboard for Your Needs

Waxed cardboard offers enhanced moisture resistance and durability, making it ideal for packaging perishable goods and items exposed to humidity. Non-waxed cardboard is more cost-effective and environmentally friendly, suitable for dry goods and general shipping purposes. Selecting between waxed and non-waxed cardboard depends on the specific storage conditions and protection requirements of your products.

Waxed cardboard vs Non-waxed cardboard Infographic

materialdif.com

materialdif.com