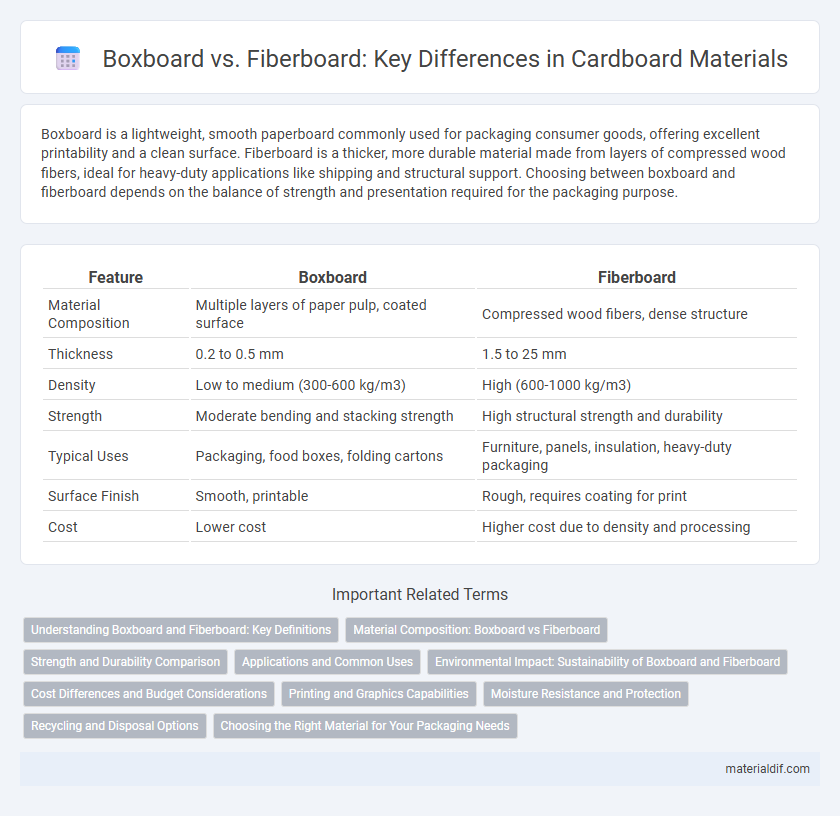

Boxboard is a lightweight, smooth paperboard commonly used for packaging consumer goods, offering excellent printability and a clean surface. Fiberboard is a thicker, more durable material made from layers of compressed wood fibers, ideal for heavy-duty applications like shipping and structural support. Choosing between boxboard and fiberboard depends on the balance of strength and presentation required for the packaging purpose.

Table of Comparison

| Feature | Boxboard | Fiberboard |

|---|---|---|

| Material Composition | Multiple layers of paper pulp, coated surface | Compressed wood fibers, dense structure |

| Thickness | 0.2 to 0.5 mm | 1.5 to 25 mm |

| Density | Low to medium (300-600 kg/m3) | High (600-1000 kg/m3) |

| Strength | Moderate bending and stacking strength | High structural strength and durability |

| Typical Uses | Packaging, food boxes, folding cartons | Furniture, panels, insulation, heavy-duty packaging |

| Surface Finish | Smooth, printable | Rough, requires coating for print |

| Cost | Lower cost | Higher cost due to density and processing |

Understanding Boxboard and Fiberboard: Key Definitions

Boxboard is a lightweight, layered paperboard primarily used for packaging smaller, less heavy products due to its smooth surface and good printing qualities. Fiberboard is a denser, thicker material made from wood fibers, offering superior strength and cushioning, commonly used for heavy-duty packaging and protective shipping containers. Understanding these distinctions helps in selecting the right material based on product weight, durability requirements, and printing needs.

Material Composition: Boxboard vs Fiberboard

Boxboard primarily consists of layers of bleached or unbleached kraft or sulfite pulp, offering a smooth surface ideal for printing and packaging applications. Fiberboard is made from wood fibers bonded together through mechanical or chemical processes, resulting in a denser and thicker material commonly used for structural packaging and insulation. The key difference in material composition lies in boxboard's layered pulp structure versus fiberboard's homogenized wood fiber matrix.

Strength and Durability Comparison

Boxboard offers moderate strength suitable for lightweight packaging, while fiberboard provides superior durability and structural integrity for heavy-duty applications. Fiberboard's dense, multi-layer construction enhances resistance to crushing and punctures compared to the thinner layers of boxboard. The increased thickness and fibrous composition of fiberboard contribute to its enhanced load-bearing capacity and long-term resilience.

Applications and Common Uses

Boxboard is widely used in packaging applications such as food containers, cereal boxes, and retail displays due to its lightweight and smooth surface ideal for printing. Fiberboard, with its thicker and denser composition, is commonly utilized in furniture manufacturing, construction panels, and shipping crates for enhanced durability and structural support. The choice between boxboard and fiberboard depends on the required strength, weight, and finish needed for specific industrial or consumer applications.

Environmental Impact: Sustainability of Boxboard and Fiberboard

Boxboard typically uses recycled fibers and has a lower carbon footprint due to its lightweight nature and efficient production process, making it a more sustainable option. Fiberboard, often made from wood fibers, can be sustainable when sourced from responsibly managed forests but generally has a higher environmental impact due to more intensive manufacturing and energy consumption. Choosing boxboard or fiberboard for packaging should consider factors like recyclability, biodegradability, and sourcing certifications to minimize environmental harm.

Cost Differences and Budget Considerations

Boxboard generally costs less than fiberboard due to its lighter weight and simpler manufacturing process, making it a more budget-friendly option for packaging needs. Fiberboard, with its thicker construction and higher durability, tends to have a higher price point but offers increased protection for heavier or fragile items. When planning budgets, choosing boxboard can reduce material expenses, while fiberboard may lead to long-term cost savings through enhanced product safety and fewer shipping damages.

Printing and Graphics Capabilities

Boxboard offers superior printing and graphics capabilities due to its smooth, coated surface that enhances ink absorption and color vibrancy for high-quality visual presentations. Fiberboard, with its rougher texture and thicker composition, typically provides less detailed print resolution, making it less ideal for intricate graphic designs. High-end packaging and retail displays favor boxboard for its ability to showcase sharp, vivid images and intricate branding elements effectively.

Moisture Resistance and Protection

Boxboard offers moderate moisture resistance due to its layered structure, making it suitable for packaging dry goods and light products. Fiberboard, composed of compressed fibers, provides higher moisture resistance and superior protection, ideal for heavier items and environments prone to humidity. The denser composition of fiberboard enhances durability and shields contents from moisture damage more effectively than boxboard.

Recycling and Disposal Options

Boxboard is typically made from layers of paper pulp and is easier to recycle through standard curbside programs, often accepted at most recycling centers due to its clean composition and lighter weight. Fiberboard, made from compressed wood fibers, can be recycled but may require specialized facilities due to its density and potential adhesives, making disposal less straightforward. Both materials are biodegradable, but improper disposal in landfills slows degradation, emphasizing the importance of proper sorting and processing for effective recycling.

Choosing the Right Material for Your Packaging Needs

Boxboard offers a lightweight, smooth surface ideal for high-quality printing and retail packaging, making it perfect for consumer goods that demand visual appeal. Fiberboard provides superior strength and durability with multiple layers of compressed fibers, suited for heavy-duty shipping and protective packaging. Selecting between boxboard and fiberboard depends on balancing aesthetic requirements with structural strength to optimize packaging performance and cost-efficiency.

Boxboard vs Fiberboard Infographic

materialdif.com

materialdif.com