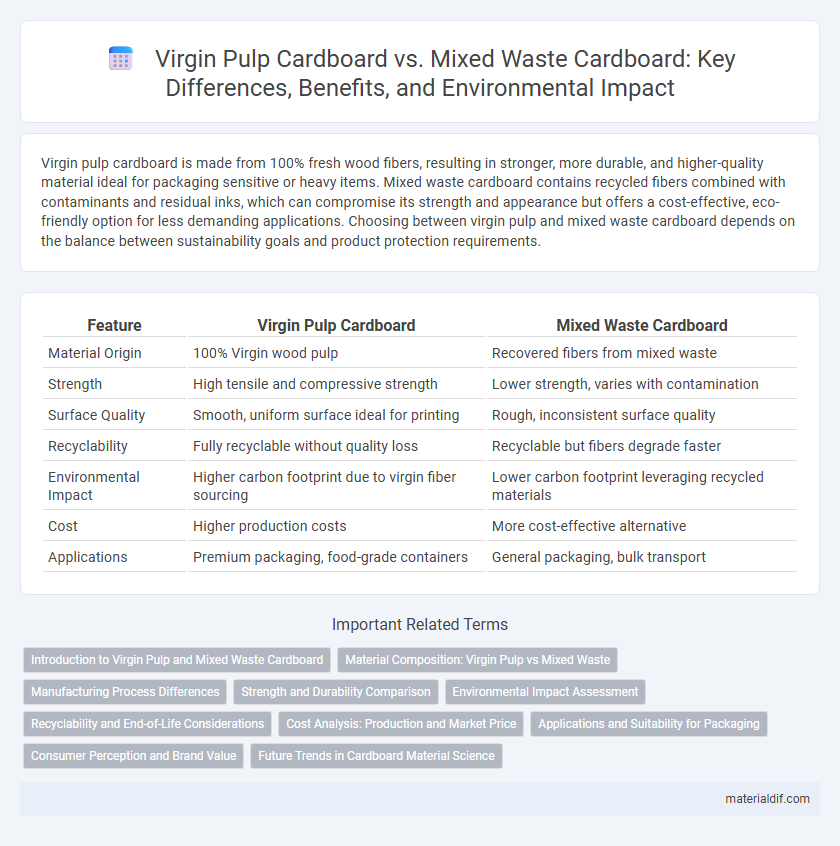

Virgin pulp cardboard is made from 100% fresh wood fibers, resulting in stronger, more durable, and higher-quality material ideal for packaging sensitive or heavy items. Mixed waste cardboard contains recycled fibers combined with contaminants and residual inks, which can compromise its strength and appearance but offers a cost-effective, eco-friendly option for less demanding applications. Choosing between virgin pulp and mixed waste cardboard depends on the balance between sustainability goals and product protection requirements.

Table of Comparison

| Feature | Virgin Pulp Cardboard | Mixed Waste Cardboard |

|---|---|---|

| Material Origin | 100% Virgin wood pulp | Recovered fibers from mixed waste |

| Strength | High tensile and compressive strength | Lower strength, varies with contamination |

| Surface Quality | Smooth, uniform surface ideal for printing | Rough, inconsistent surface quality |

| Recyclability | Fully recyclable without quality loss | Recyclable but fibers degrade faster |

| Environmental Impact | Higher carbon footprint due to virgin fiber sourcing | Lower carbon footprint leveraging recycled materials |

| Cost | Higher production costs | More cost-effective alternative |

| Applications | Premium packaging, food-grade containers | General packaging, bulk transport |

Introduction to Virgin Pulp and Mixed Waste Cardboard

Virgin pulp cardboard consists of fibers directly sourced from freshly harvested trees, ensuring high strength, purity, and durability for packaging applications. Mixed waste cardboard is produced from recycled paper fibers collected from post-consumer and post-industrial waste, resulting in a lower fiber quality but promoting sustainability and reducing landfill impact. The choice between virgin pulp and mixed waste cardboard affects product quality, environmental footprint, and cost efficiency in packaging solutions.

Material Composition: Virgin Pulp vs Mixed Waste

Virgin pulp cardboard consists entirely of fibers derived from fresh wood pulp, resulting in higher purity and strength, which makes it ideal for packaging requiring durability and a clean appearance. Mixed waste cardboard contains a blend of recycled fibers, including old newspapers, magazines, and other recovered paper products, leading to a lower fiber quality and increased impurities. The difference in material composition directly affects recyclability, printability, and overall product performance in various applications.

Manufacturing Process Differences

Virgin pulp cardboard is produced using fresh fibers derived directly from wood, involving mechanical or chemical pulping processes that ensure high fiber quality and strength. Mixed waste cardboard, on the other hand, is manufactured from recycled fibers sourced from post-consumer waste, requiring additional cleaning, deinking, and re-pulping steps to remove contaminants and improve material quality. The virgin pulp process results in more uniform and durable cardboard, whereas mixed waste cardboard manufacturing emphasizes sustainability but may yield fibers with shorter lengths and varied strength properties.

Strength and Durability Comparison

Virgin pulp cardboard exhibits superior strength and durability due to fibers that are longer and less broken, providing enhanced structural integrity and resistance to moisture. Mixed waste cardboard contains recycled fibers that are shorter and weakened by contaminants, resulting in reduced tensile strength and lower resilience under stress. This difference makes virgin pulp cardboard ideal for applications requiring high load-bearing capacity and prolonged durability.

Environmental Impact Assessment

Virgin pulp cardboard, derived directly from fresh wood fibers, generally exhibits higher environmental impacts due to deforestation, energy-intensive processing, and significant water consumption. Mixed waste cardboard, sourced from recycled materials, reduces landfill waste and lowers greenhouse gas emissions but may involve complex sorting and decontamination steps that affect overall efficiency. Lifecycle assessments consistently show that using recycled fibers in cardboard production substantially decreases carbon footprint and resource depletion compared to virgin pulp alternatives.

Recyclability and End-of-Life Considerations

Virgin pulp cardboard offers higher recyclability due to its purity and minimal contamination, enabling more efficient processing and producing higher quality recycled fibers. Mixed waste cardboard often contains impurities such as inks, adhesives, and food residues, which complicate recycling efforts and reduce the quality of the recycled material. End-of-life considerations favor virgin pulp cardboard for closed-loop recycling systems, whereas mixed waste cardboard may require energy recovery or landfilling if contamination limits recycling options.

Cost Analysis: Production and Market Price

Virgin pulp cardboard commands higher production costs due to the extensive use of fresh wood fibers and energy-intensive manufacturing processes, resulting in a superior but more expensive product. Mixed waste cardboard, derived from recycled materials, offers significantly lower production expenses by minimizing raw material and energy inputs, which translates to more competitive market prices. Market trends show virgin pulp cardboard maintains higher pricing due to quality preferences, while mixed waste cardboard dominates cost-sensitive sectors with its affordability and sustainability benefits.

Applications and Suitability for Packaging

Virgin pulp cardboard offers superior strength, durability, and printability, making it ideal for high-quality packaging such as luxury goods and food containers. Mixed waste cardboard, composed of recycled fibers, provides cost-effective and eco-friendly packaging solutions suitable for secondary packaging and shipping boxes. Both materials serve distinct roles in packaging, with virgin pulp ensuring product protection and aesthetics, while mixed waste supports sustainability and budget-conscious applications.

Consumer Perception and Brand Value

Virgin pulp cardboard is often perceived by consumers as higher quality and more environmentally friendly, enhancing brand value through a premium, sustainable image. Mixed waste cardboard, associated with recycled content, can sometimes be viewed as lower quality, which may impact consumer trust and diminish perceived brand prestige. Brands leveraging virgin pulp materials emphasize purity and durability, reinforcing consumer confidence and elevating market reputation.

Future Trends in Cardboard Material Science

Future trends in cardboard material science emphasize the development of sustainable virgin pulp alternatives and advanced recycling technologies for mixed waste cardboard. Innovations include enzymatic treatments and bio-based additives that enhance strength and recyclability while reducing environmental impact. Emerging market demands drive research towards hybrid materials combining virgin pulp purity with mixed waste versatility to optimize performance and circular economy goals.

Virgin pulp cardboard vs Mixed waste cardboard Infographic

materialdif.com

materialdif.com