E-flute offers thinner, more compact corrugation compared to B-flute, making it ideal for packaging small, delicate items that require better print definition and smoother surface appearance. B-flute has a thicker profile providing greater cushioning and stacking strength, suited for heavier or bulkier products needing more protection during handling and shipping. Choosing between E-flute and B-flute depends on the balance between protection needs and the presentation of the packaged goods.

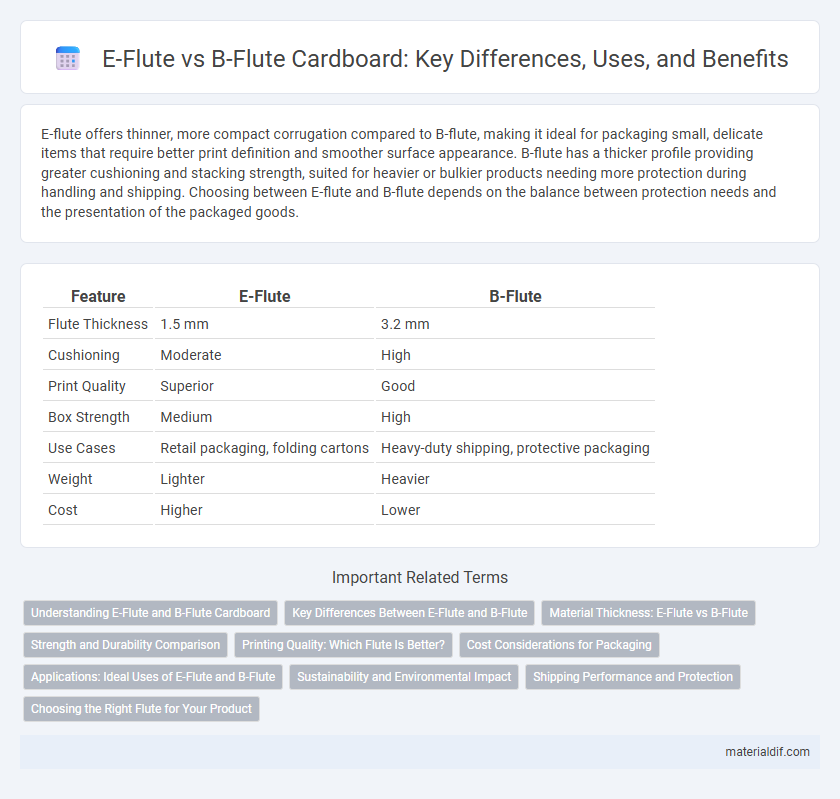

Table of Comparison

| Feature | E-Flute | B-Flute |

|---|---|---|

| Flute Thickness | 1.5 mm | 3.2 mm |

| Cushioning | Moderate | High |

| Print Quality | Superior | Good |

| Box Strength | Medium | High |

| Use Cases | Retail packaging, folding cartons | Heavy-duty shipping, protective packaging |

| Weight | Lighter | Heavier |

| Cost | Higher | Lower |

Understanding E-Flute and B-Flute Cardboard

E-flute cardboard measures approximately 1.6 mm in thickness, offering a smooth surface ideal for high-quality printing and packaging of small to medium-sized products. B-flute cardboard, thicker at about 3.2 mm, provides superior cushioning and stacking strength, making it suitable for heavier or fragile items. Understanding the differences between E-flute and B-flute helps in selecting the appropriate board for durability, protection, and presentation in packaging solutions.

Key Differences Between E-Flute and B-Flute

E-flute cardboard features a thickness of approximately 1.5mm, offering superior cushioning and a smoother surface ideal for high-quality printing, while B-flute measures about 3.2mm, providing greater stacking strength and impact resistance. E-flute is commonly used for retail packaging and small, lightweight items due to its fine flute profile, whereas B-flute is preferred for shipping heavier products requiring sturdier protection. The choice between E-flute and B-flute affects packaging durability, print clarity, and cost efficiency, making it essential to match flute type with specific product needs.

Material Thickness: E-Flute vs B-Flute

E-Flute cardboard typically measures about 1.5 mm in thickness, offering a smoother surface ideal for retail packaging and detailed printing. B-Flute cardboard is thicker, approximately 3.2 mm, providing greater cushioning and strength suited for shipping heavier products. The choice between E-Flute and B-Flute depends on balancing protection requirements with the need for visual appeal and cost-effectiveness.

Strength and Durability Comparison

E-flute cardboard features a thinner profile with approximately 1.5mm thickness, offering enhanced printability and a smoother surface, while B-flute measures around 3.2mm, providing greater cushioning and impact resistance. In strength and durability, B-flute excels due to its thicker thickness and higher stacking strength, making it ideal for heavy-duty packaging and protection during shipping. E-flute, despite being less robust, offers superior rigidity and is better suited for retail packaging where structural integrity combined with visual appeal is critical.

Printing Quality: Which Flute Is Better?

E-flute cardboard offers superior printing quality compared to B-flute due to its thinner profile and smoother surface, which allows for finer details and sharper images in printing processes. The higher flute density in E-flute provides better resolution for graphics and text, making it ideal for high-quality packaging designs. B-flute, being thicker and more rigid, is less capable of capturing intricate print details, leading to more muted or less precise visuals.

Cost Considerations for Packaging

E-flute cardboard offers a cost-effective solution for packaging due to its thinner profile, which reduces material usage and shipping weight. B-flute cardboard, while slightly thicker and more expensive, provides better cushioning and strength for heavier or more fragile items, potentially lowering damage-related costs. Choosing between E-flute and B-flute depends on balancing packaging protection needs with budget constraints to optimize overall cost efficiency.

Applications: Ideal Uses of E-Flute and B-Flute

E-flute cardboard, with a thickness of approximately 1.5 mm, is ideal for packaging small, lightweight items requiring high-quality printing and moisture resistance, such as cosmetics, pharmaceuticals, and electronics. B-flute, at around 3 mm thick, offers superior cushioning and stacking strength, making it suitable for shipping heavier goods like glassware, appliances, and industrial products. Choosing between E-flute and B-flute depends on the balance between protection, presentation, and shipping requirements of the packaged item.

Sustainability and Environmental Impact

E-flute cardboard offers enhanced sustainability benefits compared to B-flute due to its thinner profile, which requires less raw material and results in lighter packaging, reducing transportation emissions. B-flute, while providing greater cushioning, consumes more paper fiber, leading to higher resource use and increased waste. Choosing E-flute supports eco-friendly initiatives by minimizing deforestation and lowering the carbon footprint associated with packaging production.

Shipping Performance and Protection

E-flute cardboard offers superior crush resistance and cushioning, making it ideal for protecting fragile items during shipping. B-flute cardboard, thicker with fewer flutes per inch, provides enhanced strength and stacking performance, suitable for heavier shipments. Choosing between E-flute and B-flute depends on the balance between protection requirements and shipping efficiency.

Choosing the Right Flute for Your Product

E-flute cardboard, with a thickness of approximately 1.5 mm, offers a smoother surface ideal for high-quality printing and detailed graphics, making it perfect for retail packaging and point-of-purchase displays. B-flute cardboard measures around 3.2 mm thick, providing superior cushioning and stacking strength suited for heavier or fragile items during shipping and storage. Selecting between E-flute and B-flute depends on balancing the need for protection versus printability based on the product's fragility and marketing requirements.

E-flute vs B-flute Infographic

materialdif.com

materialdif.com