Single-wall board consists of one layer of fluted corrugated paper sandwiched between two linerboards, providing lightweight protection ideal for shipping lighter items. Double-wall board features two layers of fluted corrugated paper and three linerboards, offering enhanced strength and durability suited for heavier or fragile products. Choosing between single-wall and double-wall board depends on the required cushioning, weight capacity, and protection during transit.

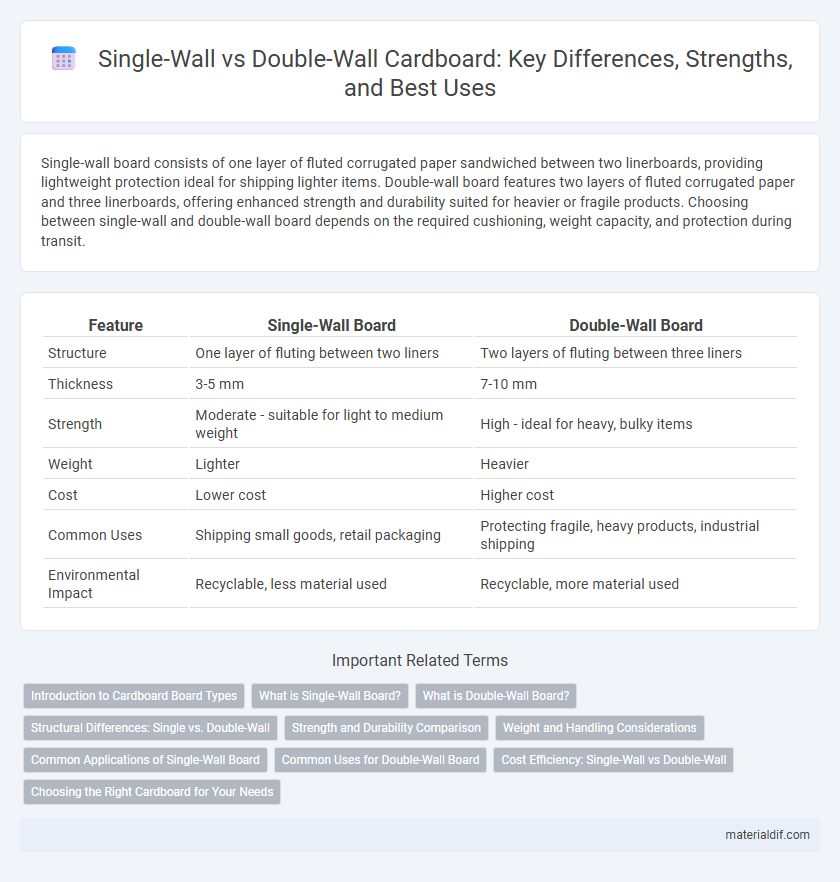

Table of Comparison

| Feature | Single-Wall Board | Double-Wall Board |

|---|---|---|

| Structure | One layer of fluting between two liners | Two layers of fluting between three liners |

| Thickness | 3-5 mm | 7-10 mm |

| Strength | Moderate - suitable for light to medium weight | High - ideal for heavy, bulky items |

| Weight | Lighter | Heavier |

| Cost | Lower cost | Higher cost |

| Common Uses | Shipping small goods, retail packaging | Protecting fragile, heavy products, industrial shipping |

| Environmental Impact | Recyclable, less material used | Recyclable, more material used |

Introduction to Cardboard Board Types

Single-wall board consists of one layer of fluted paper sandwiched between two liners, offering lightweight strength suited for standard packaging needs. Double-wall board features two layers of fluting and three liners, providing enhanced durability and protection for heavier, fragile products. Choosing the right cardboard board type depends on the weight, fragility, and shipping requirements of the items being packaged.

What is Single-Wall Board?

Single-wall board consists of one layer of fluted paper sandwiched between two liners, providing a lightweight yet durable packaging solution ideal for shipping and protecting lightweight to medium-weight items. It offers good cushioning and stacking strength while maintaining cost-effectiveness and recyclability, making it a popular choice for everyday shipping needs. Single-wall board is widely used in retail packaging, shipping boxes, and storage containers due to its efficient balance between strength and material consumption.

What is Double-Wall Board?

Double-wall board consists of two layers of fluted corrugation sandwiched between three flat linerboards, offering enhanced strength and durability compared to single-wall board. This construction provides superior resistance to crushing, punctures, and external impacts, making it ideal for packaging heavy or fragile items. Double-wall board is commonly used in industrial shipping and storage where extra protection is essential.

Structural Differences: Single vs. Double-Wall

Single-wall board consists of one layer of fluted paper between two flat liners, providing moderate strength and flexibility ideal for lightweight packaging. Double-wall board features two layers of fluted paper sandwiched between three liners, significantly enhancing rigidity, impact resistance, and load-bearing capacity. These structural differences make double-wall board more suitable for heavy or fragile items requiring extra protection during shipping and storage.

Strength and Durability Comparison

Single-wall board features a single layer of corrugated medium between two liners, providing moderate strength suitable for lightweight packaging and short-term use. Double-wall board consists of two layers of corrugated medium separated by three liners, offering significantly enhanced strength and durability ideal for heavy or fragile items requiring extended protection. The increased thickness and structural integrity of double-wall board make it resistant to crushing, punctures, and moisture, outperforming single-wall in demanding shipping environments.

Weight and Handling Considerations

Single-wall cardboard typically weighs less, making it easier to handle and ideal for lightweight packaging needs. Double-wall board offers increased strength and durability but comes with added weight, which may require more effort during handling and transportation. Choosing between single-wall and double-wall depends on balancing the weight requirements with the need for protection and ease of handling.

Common Applications of Single-Wall Board

Single-wall board, composed of one layer of corrugated medium sandwiched between two liners, is widely used in packaging for lightweight products such as electronics, food items, and retail goods. Its balance of strength and flexibility makes it ideal for shipping boxes, point-of-sale displays, and protective packaging where moderate cushioning is sufficient. Single-wall board offers cost-effective solutions for businesses requiring efficient transport and storage without excessive material bulk.

Common Uses for Double-Wall Board

Double-wall board is commonly used for shipping heavy or fragile items because its two layers of fluting provide enhanced strength and cushioning compared to single-wall board. Industries such as electronics, automotive parts, and glassware packaging frequently rely on double-wall board to ensure products remain protected during transit. Its durability and resistance to punctures make it ideal for long-distance transportation and stacking in warehouses.

Cost Efficiency: Single-Wall vs Double-Wall

Single-wall board offers superior cost efficiency due to its lower material and manufacturing expenses, making it ideal for lightweight packaging needs. Double-wall board provides enhanced durability and protection but at a higher cost, suitable for shipping heavier or fragile items. Businesses balance these cost differences by choosing single-wall for budget-friendly, less demanding applications and double-wall when strength and security justify the additional investment.

Choosing the Right Cardboard for Your Needs

Single-wall board offers lightweight protection suitable for everyday packaging and shipping of less fragile items, making it cost-effective and easy to handle. Double-wall board provides enhanced strength and durability with two layers of fluting, ideal for heavier or more fragile products that require extra cushioning during transit. Selecting the right cardboard depends on factors such as product weight, fragility, and shipping duration to ensure optimal protection and cost efficiency.

Single-wall board vs Double-wall board Infographic

materialdif.com

materialdif.com