C-flute cardboard offers superior cushioning and strength, making it ideal for packaging larger or heavier pet products, while E-flute cardboard provides a thinner, more rigid structure suited for smaller, lightweight items requiring fine printing detail. The choice between C-flute and E-flute affects durability, protection, and aesthetic appeal in pet packaging. Selecting the appropriate flute type ensures pet products are secure and visually attractive during shipping and display.

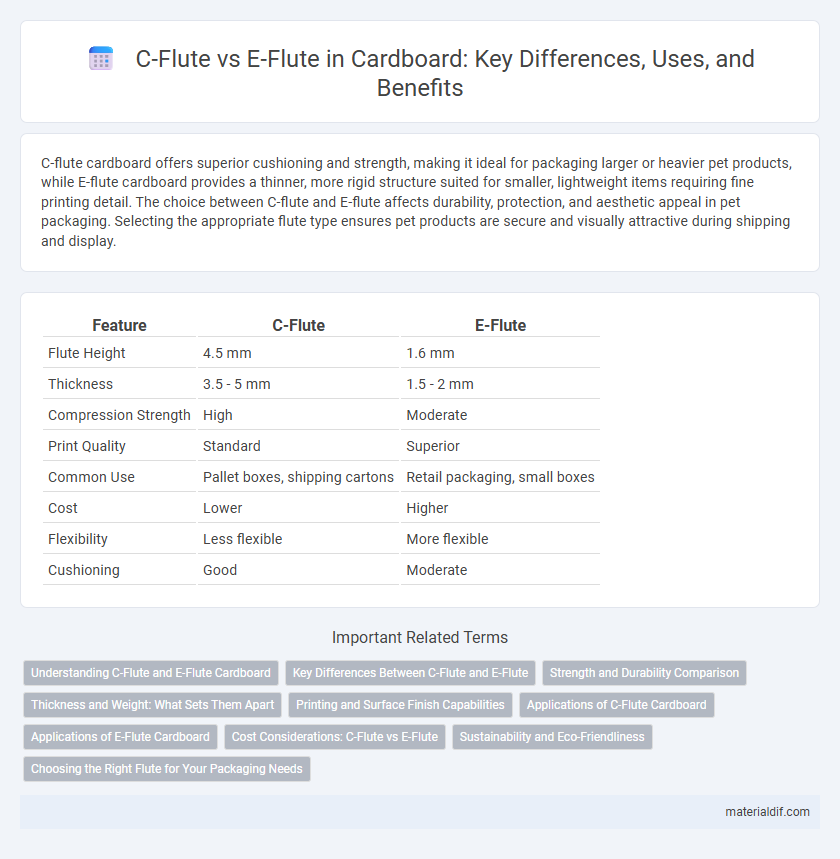

Table of Comparison

| Feature | C-Flute | E-Flute |

|---|---|---|

| Flute Height | 4.5 mm | 1.6 mm |

| Thickness | 3.5 - 5 mm | 1.5 - 2 mm |

| Compression Strength | High | Moderate |

| Print Quality | Standard | Superior |

| Common Use | Pallet boxes, shipping cartons | Retail packaging, small boxes |

| Cost | Lower | Higher |

| Flexibility | Less flexible | More flexible |

| Cushioning | Good | Moderate |

Understanding C-Flute and E-Flute Cardboard

C-flute cardboard features a thickness of approximately 3.6 mm, offering strong cushioning and excellent stacking strength, making it ideal for shipping heavier items. E-flute cardboard is thinner at about 1.6 mm, providing a smoother surface for high-quality printing and enhanced product visibility, commonly used in retail packaging. Choosing between C-flute and E-flute depends on the balance between protective durability and presentation quality needed for specific packaging requirements.

Key Differences Between C-Flute and E-Flute

C-flute corrugated cardboard features a thickness of approximately 3.6mm, offering superior cushioning and durability ideal for shipping heavy or fragile items, while E-flute, with a thinner profile around 1.6mm, provides a smoother surface suitable for high-quality printing and retail packaging. C-flute's larger flutes deliver better stacking strength and impact resistance, whereas E-flute excels in space efficiency, lightweight packaging, and enhanced graphical presentation. The choice between C-flute and E-flute largely depends on balancing protection needs with aesthetic requirements and material cost considerations.

Strength and Durability Comparison

C-flute cardboard features a thicker profile with approximately 3/16 inch flute height, providing superior strength and cushioning suitable for heavy-duty packaging. E-flute has a thinner profile around 1/16 inch, offering a smoother surface ideal for printing and light-to-medium weight protection. Strength and durability favor C-flute for impact resistance and stacking strength, while E-flute excels in durability for delicate items requiring precision packaging.

Thickness and Weight: What Sets Them Apart

C-flute cardboard typically measures about 3.5 mm in thickness, providing a strong and rigid structure ideal for heavy-duty packaging, while E-flute is thinner at approximately 1.5 mm, offering a lightweight yet durable option suited for retail displays and smaller boxes. The density of C-flute results in greater cushioning and stacking strength, making it preferable for shipping heavier items, whereas E-flute's reduced thickness optimizes space and material cost without sacrificing adequate protection for lighter products. Weight differences impact shipping costs and handling; C-flute is heavier and bulkier, whereas E-flute is lighter and more compact, enhancing efficiency in packaging design.

Printing and Surface Finish Capabilities

C-flute cardboard offers a thicker profile with better cushioning, ideal for printing large graphics and bold colors due to its sturdier surface but may have lower image resolution. E-flute cardboard features a thinner, finer flute structure that allows for higher-quality printing with sharper details and smoother surface finishes, making it perfect for intricate designs and premium packaging. Choosing between C-flute and E-flute depends on the balance between durability needs and the desired print quality for the packaging application.

Applications of C-Flute Cardboard

C-flute cardboard is widely used in packaging applications requiring superior cushioning and protection, such as shipping boxes for electronics, glassware, and heavy-duty consumer goods. Its thickness, typically 3.6 to 4.0 mm, provides enhanced stacking strength and impact resistance compared to thinner flutes like E-flute. Industries rely on C-flute cardboard for corrugated boxes that balance durability with cost-effectiveness in distribution and storage.

Applications of E-Flute Cardboard

E-flute cardboard, characterized by its thinner profile of approximately 1.6 mm thickness, is ideal for packaging delicate products such as cosmetics, electronics, and retail food items due to its superior printability and cushioning properties. Its fine flute structure provides a smooth surface for high-quality graphics, making it a preferred choice for retail packaging and point-of-purchase displays. E-flute's lightweight nature offers enhanced protection while reducing shipping costs compared to thicker flutes like C-flute.

Cost Considerations: C-Flute vs E-Flute

C-flute cardboard offers a cost-effective solution with thicker flutes providing enhanced cushioning at a lower price per sheet compared to E-flute. E-flute, while more expensive, delivers superior printability and a smoother surface ideal for high-quality packaging and branding. Businesses weighing cost considerations must balance C-flute's affordability and durability against E-flute's premium finish and reduced material usage for lightweight packaging.

Sustainability and Eco-Friendliness

C-flute cardboard offers greater thickness and cushioning, enabling better reuse and durability, which reduces waste over time. E-flute is thinner and uses less raw material, making it more eco-friendly for lightweight packaging and promoting material efficiency. Both flutes support recyclability, but choosing E-flute lowers environmental impact by minimizing resource consumption during production.

Choosing the Right Flute for Your Packaging Needs

Choosing the right flute for your packaging depends on the balance between cushioning and printability. C-flute offers about 39 flutes per foot, providing excellent strength and durability for heavier items and better resistance to crushing. E-flute, with approximately 60 flutes per foot, delivers a thinner profile ideal for detailed printing and lightweight products, ensuring a smooth surface and efficient space usage.

C-flute vs E-flute Infographic

materialdif.com

materialdif.com