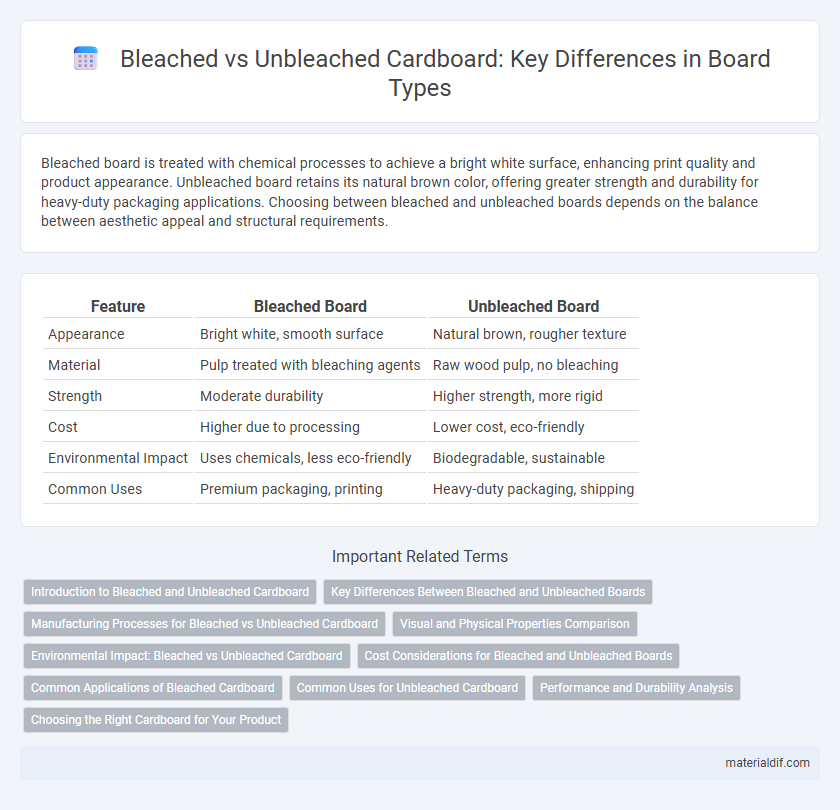

Bleached board is treated with chemical processes to achieve a bright white surface, enhancing print quality and product appearance. Unbleached board retains its natural brown color, offering greater strength and durability for heavy-duty packaging applications. Choosing between bleached and unbleached boards depends on the balance between aesthetic appeal and structural requirements.

Table of Comparison

| Feature | Bleached Board | Unbleached Board |

|---|---|---|

| Appearance | Bright white, smooth surface | Natural brown, rougher texture |

| Material | Pulp treated with bleaching agents | Raw wood pulp, no bleaching |

| Strength | Moderate durability | Higher strength, more rigid |

| Cost | Higher due to processing | Lower cost, eco-friendly |

| Environmental Impact | Uses chemicals, less eco-friendly | Biodegradable, sustainable |

| Common Uses | Premium packaging, printing | Heavy-duty packaging, shipping |

Introduction to Bleached and Unbleached Cardboard

Bleached cardboard undergoes a chemical treatment that removes lignin and impurities, resulting in a bright white, smooth surface ideal for high-quality printing and packaging. Unbleached cardboard retains its natural brown color and fibers, offering increased strength and environmental benefits due to the absence of harsh chemical processing. Both types serve distinct purposes, with bleached board favored for aesthetic appeal and unbleached board prioritized for durability and sustainability.

Key Differences Between Bleached and Unbleached Boards

Bleached board undergoes a chemical process to remove lignin and brighten the fibers, resulting in a smoother, whiter surface ideal for high-end packaging and printing. Unbleached board retains its natural brown color and fiber strength, offering greater durability and environmental benefits due to minimal processing. Key differences include appearance, strength, cost, and environmental impact, with bleached boards preferred for aesthetics and unbleached for robustness and sustainability.

Manufacturing Processes for Bleached vs Unbleached Cardboard

Bleached cardboard undergoes chemical treatments to remove lignin and impurities, resulting in a whiter, more uniform surface ideal for high-quality printing and packaging. Unbleached cardboard retains its natural brown color by skipping the bleaching stage, preserving fiber strength and requiring fewer chemicals, which reduces environmental impact. The manufacturing process for bleached board involves additional stages such as chlorine or oxygen-based bleaching, whereas unbleached board uses mechanical pulping with minimal chemical intervention.

Visual and Physical Properties Comparison

Bleached board features a bright white appearance due to chemical treatment, enhancing visual appeal and making it ideal for high-quality printing and packaging. Unbleached board retains its natural brown color, offering a more rustic look and greater rigidity, which improves durability and strength for heavy-duty applications. Physically, bleached board tends to be smoother and less porous, while unbleached board provides better resistance to moisture and a sturdier texture.

Environmental Impact: Bleached vs Unbleached Cardboard

Bleached cardboard undergoes chemical treatment to achieve its white color, often involving chlorine-based agents that can produce harmful byproducts and increase water pollution. Unbleached cardboard uses natural fibers without chemical whitening, resulting in a lower ecological footprint and reduced water contamination. Choosing unbleached cardboard supports more sustainable packaging solutions by minimizing toxic waste and promoting biodegradable, eco-friendly materials.

Cost Considerations for Bleached and Unbleached Boards

Bleached board typically incurs higher production costs due to the additional chemical processing required to achieve its white, smooth surface, making it more expensive than unbleached board. Unbleached board, produced with less processing and retaining its natural brown color, offers a cost-effective alternative ideal for packaging where aesthetics are less critical. Choosing between bleached and unbleached boards often depends on budget constraints and the desired appearance of the final product.

Common Applications of Bleached Cardboard

Bleached cardboard is commonly used in packaging applications where a clean, bright appearance is essential, such as in food packaging, cosmetics, and pharmaceutical boxes. Its smooth, white surface enhances print quality, making it ideal for branding and high-end product presentation. The material's resistance to moisture and contaminants also makes it suitable for direct food contact and shelf-ready packaging.

Common Uses for Unbleached Cardboard

Unbleached cardboard is commonly used for packaging heavy-duty items such as food products, electronics, and industrial goods due to its natural brown color and superior strength. Its uncoated surface makes it ideal for eco-friendly packaging and shipping boxes that require durability without chemical treatments. This type of cardboard is preferred in applications where environmental impact and recyclability are important factors.

Performance and Durability Analysis

Bleached board offers enhanced surface smoothness and brightness, improving print quality and making it ideal for high-end packaging applications requiring a clean appearance. Unbleached board provides superior strength and durability due to its natural fiber retention, which enhances resistance to moisture and rough handling in shipping contexts. Performance analysis reveals that unbleached board excels in structural integrity, while bleached board prioritizes aesthetic appeal without significantly compromising durability for less demanding uses.

Choosing the Right Cardboard for Your Product

Bleached board features a white, smooth surface ideal for high-end product packaging that demands vibrant printing and a clean appearance. Unbleached board, with its natural brown color and greater rigidity, offers superior strength and is preferred for heavy-duty or eco-friendly packaging needs. Selecting the right cardboard depends on balancing aesthetic requirements with durability, where bleached board excels in presentation and unbleached board prioritizes environmental sustainability and structural integrity.

Bleached board vs Unbleached board Infographic

materialdif.com

materialdif.com