Laminated cardboard offers enhanced durability and moisture resistance, making it ideal for long-lasting pet products, while non-laminated cardboard tends to absorb liquids and wear out more quickly. The smooth surface of laminated cardboard also provides a cleaner, more appealing look and prevents fraying edges that can occur with non-laminated options. Choosing laminated cardboard ensures better protection and aesthetics for pet items exposed to daily use.

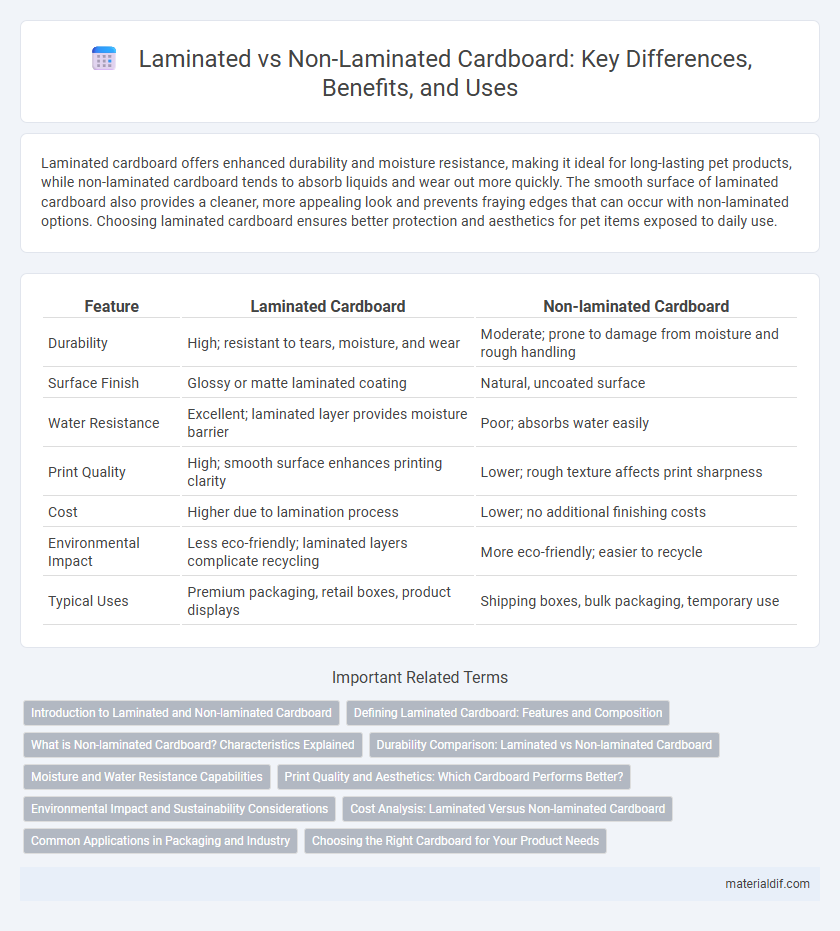

Table of Comparison

| Feature | Laminated Cardboard | Non-laminated Cardboard |

|---|---|---|

| Durability | High; resistant to tears, moisture, and wear | Moderate; prone to damage from moisture and rough handling |

| Surface Finish | Glossy or matte laminated coating | Natural, uncoated surface |

| Water Resistance | Excellent; laminated layer provides moisture barrier | Poor; absorbs water easily |

| Print Quality | High; smooth surface enhances printing clarity | Lower; rough texture affects print sharpness |

| Cost | Higher due to lamination process | Lower; no additional finishing costs |

| Environmental Impact | Less eco-friendly; laminated layers complicate recycling | More eco-friendly; easier to recycle |

| Typical Uses | Premium packaging, retail boxes, product displays | Shipping boxes, bulk packaging, temporary use |

Introduction to Laminated and Non-laminated Cardboard

Laminated cardboard features a protective plastic or wax coating that enhances durability, moisture resistance, and structural integrity, making it ideal for packaging sensitive items. Non-laminated cardboard lacks this coating, offering a more economical and easily recyclable option but with reduced water resistance and strength. Both types serve distinct purposes in industries such as shipping, retail, and food packaging, depending on the required level of protection and environmental considerations.

Defining Laminated Cardboard: Features and Composition

Laminated cardboard consists of multiple layers of paperboard bonded together with a plastic film or coating, enhancing durability and moisture resistance compared to non-laminated cardboard. The lamination process provides a glossy finish, increased strength, and protection against wear, making it ideal for packaging sensitive or high-end products. Non-laminated cardboard, while more cost-effective and recyclable, lacks the added resilience and aesthetic appeal offered by laminated variants.

What is Non-laminated Cardboard? Characteristics Explained

Non-laminated cardboard is a durable paper-based material composed of multiple layers of paper fibers without a plastic or glossy coating. It offers a natural, matte finish that is highly breathable and recyclable, making it an eco-friendly choice for packaging and printing applications. This type of cardboard is more susceptible to moisture and abrasion compared to laminated cardboard but provides excellent printability and cost efficiency.

Durability Comparison: Laminated vs Non-laminated Cardboard

Laminated cardboard exhibits superior durability compared to non-laminated cardboard due to its protective coating, which enhances resistance to moisture, abrasion, and tearing. Non-laminated cardboard lacks this barrier, making it more susceptible to damage and reducing its lifespan in high-humidity or rough handling conditions. The lamination process significantly extends the functional use of cardboard in packaging, storage, and shipping applications.

Moisture and Water Resistance Capabilities

Laminated cardboard features a protective plastic or wax coating that significantly enhances its moisture and water resistance, making it ideal for packaging items exposed to damp environments. Non-laminated cardboard lacks this barrier, resulting in lower durability and higher susceptibility to warping or degradation when exposed to water. For applications requiring robust protection against moisture, laminated cardboard outperforms non-laminated options by maintaining structural integrity and preventing water absorption.

Print Quality and Aesthetics: Which Cardboard Performs Better?

Laminated cardboard offers superior print quality and enhanced aesthetics due to its smooth, glossy surface that allows for vibrant colors and sharp details, making it ideal for high-end packaging and promotional materials. Non-laminated cardboard, with its natural, matte finish, provides a more rustic and eco-friendly appearance but often results in less vivid prints and a coarser texture that can affect design clarity. For applications prioritizing visual impact and premium presentation, laminated cardboard consistently outperforms non-laminated options in both print fidelity and overall visual appeal.

Environmental Impact and Sustainability Considerations

Laminated cardboard typically involves a plastic coating that hinders its recyclability and prolongs decomposition, posing greater environmental challenges compared to non-laminated cardboard, which is biodegradable and more easily processed in standard recycling streams. Non-laminated cardboard supports circular economy principles by facilitating reuse and efficient recycling, reducing landfill waste and lowering carbon emissions. Sustainable packaging practices prioritize non-laminated cardboard due to its minimal environmental footprint and compatibility with eco-friendly disposal methods.

Cost Analysis: Laminated Versus Non-laminated Cardboard

Laminated cardboard generally incurs higher costs due to additional materials and processing steps involved in adding a protective film, which enhances durability and moisture resistance. Non-laminated cardboard remains more cost-effective for bulk packaging needs where exposure to external elements is minimal. Businesses must weigh the increased upfront investment of laminated options against potential savings from reduced product damage and extended shelf life.

Common Applications in Packaging and Industry

Laminated cardboard is widely used in packaging for products that require moisture resistance and enhanced durability, such as food containers, premium cosmetics, and electronics packaging. Non-laminated cardboard is commonly applied in shipping boxes, product dividers, and bulk packaging where cost efficiency and recyclability are prioritized. Both types serve critical roles in industrial packaging, with laminated variants offering superior protection and non-laminated options favored for sustainable, lightweight applications.

Choosing the Right Cardboard for Your Product Needs

Laminated cardboard offers enhanced durability, moisture resistance, and a sleek finish, making it ideal for premium packaging and products requiring extra protection. Non-laminated cardboard provides a more eco-friendly and cost-effective option suitable for lightweight or disposable packaging where sustainability is a priority. Selecting the right cardboard depends on product fragility, presentation needs, and environmental considerations to ensure optimal performance and customer satisfaction.

Laminated Cardboard vs Non-laminated Cardboard Infographic

materialdif.com

materialdif.com