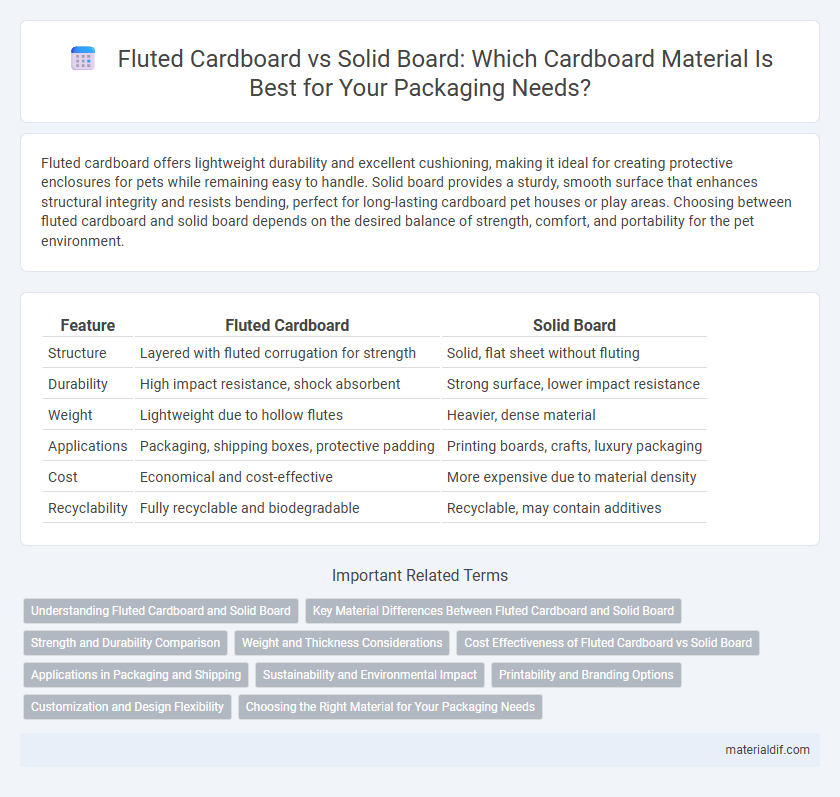

Fluted cardboard offers lightweight durability and excellent cushioning, making it ideal for creating protective enclosures for pets while remaining easy to handle. Solid board provides a sturdy, smooth surface that enhances structural integrity and resists bending, perfect for long-lasting cardboard pet houses or play areas. Choosing between fluted cardboard and solid board depends on the desired balance of strength, comfort, and portability for the pet environment.

Table of Comparison

| Feature | Fluted Cardboard | Solid Board |

|---|---|---|

| Structure | Layered with fluted corrugation for strength | Solid, flat sheet without fluting |

| Durability | High impact resistance, shock absorbent | Strong surface, lower impact resistance |

| Weight | Lightweight due to hollow flutes | Heavier, dense material |

| Applications | Packaging, shipping boxes, protective padding | Printing boards, crafts, luxury packaging |

| Cost | Economical and cost-effective | More expensive due to material density |

| Recyclability | Fully recyclable and biodegradable | Recyclable, may contain additives |

Understanding Fluted Cardboard and Solid Board

Fluted cardboard consists of a corrugated layer sandwiched between two flat linerboards, providing strength and cushioning ideal for shipping and packaging. Solid board is a dense, rigid paperboard without corrugation, offering a smooth surface suitable for printing and retail packaging. Understanding the structural differences helps in selecting the right material based on durability requirements, weight considerations, and aesthetic needs.

Key Material Differences Between Fluted Cardboard and Solid Board

Fluted cardboard consists of a corrugated medium sandwiched between two linerboards, providing enhanced strength and cushioning due to its unique fluted structure. In contrast, solid board is a dense, single-ply sheet made from compressed fibers, offering a smooth surface and rigidity but less flexibility and cushioning. The key material differences lie in fluted cardboard's combination of air pockets and liners for impact resistance, whereas solid board relies on fiber density for durability and print quality.

Strength and Durability Comparison

Fluted cardboard features multiple layers with a corrugated middle layer, providing enhanced strength and shock absorption, making it ideal for packaging fragile items. Solid board consists of compact fibers with a smooth surface, offering superior rigidity and resistance to punctures but less flexibility under pressure. In terms of durability, fluted cardboard excels in impact resistance, while solid board maintains structural integrity under heavy loads and repeated handling.

Weight and Thickness Considerations

Fluted cardboard typically offers a lighter weight and greater thickness due to its corrugated structure, providing enhanced cushioning and impact resistance compared to solid board. Solid board, being denser and more compact, generally weighs more but has a thinner profile, making it suitable for packaging requiring a rigid, smooth surface. Weight and thickness considerations directly influence material choice based on the need for durability, protection, and structural integrity in packaging applications.

Cost Effectiveness of Fluted Cardboard vs Solid Board

Fluted cardboard offers significant cost-effectiveness compared to solid board due to its lightweight structure and efficient use of raw materials, which reduces manufacturing expenses. Its layered design with air pockets provides strength and durability at a lower price point than the denser, heavier solid board. Businesses often choose fluted cardboard for packaging when balancing protection with budget constraints, making it a preferred option for bulk shipping and retail packaging.

Applications in Packaging and Shipping

Fluted cardboard, characterized by its corrugated structure, offers superior cushioning and impact resistance, making it ideal for protecting fragile items during shipping and handling. Solid board provides a smooth surface and greater rigidity, often used for retail packaging, folding cartons, and point-of-sale displays where print quality and presentation are paramount. Both materials serve distinct roles in packaging: fluted cardboard excels in protective shipping containers, while solid board is preferred for branding and product display.

Sustainability and Environmental Impact

Fluted cardboard, made from recycled paper fibers and designed with a corrugated structure, offers superior sustainability due to its high recyclability and biodegradability compared to solid board, which often uses denser, virgin paper fibers. Its lightweight yet strong composition reduces transportation emissions and resource consumption, making it an eco-friendly packaging solution. Solid board, while durable and protective, typically has a larger environmental footprint due to higher material use and limited recyclability.

Printability and Branding Options

Fluted cardboard offers superior printability due to its textured surface that enhances ink adhesion and vibrancy, making it ideal for detailed branding and eye-catching designs. Solid board provides a smooth, rigid surface that supports high-quality printing with precise graphics and rich color saturation, often preferred for premium packaging with sophisticated branding. Both materials accommodate various print techniques such as flexography, digital, and screen printing, but fluted cardboard excels in cost-effective, large-scale branding campaigns.

Customization and Design Flexibility

Fluted cardboard offers enhanced customization and design flexibility due to its layered structure, allowing for varied thicknesses and board strengths tailored to specific packaging needs. Solid board, while providing a smooth surface ideal for high-quality printing and detailed graphic designs, is less adaptable in terms of structural modifications. Choosing between fluted cardboard and solid board depends on the balance required between durability, print quality, and the degree of customization in packaging design.

Choosing the Right Material for Your Packaging Needs

Fluted cardboard offers superior cushioning and impact resistance due to its layered, corrugated structure, making it ideal for shipping fragile items. Solid board provides a smooth, rigid surface with excellent printability, preferred for retail packaging and luxury product presentation. Selecting the right material depends on balancing protection requirements, aesthetic appeal, and cost-efficiency for your specific packaging application.

Fluted Cardboard vs Solid Board Infographic

materialdif.com

materialdif.com