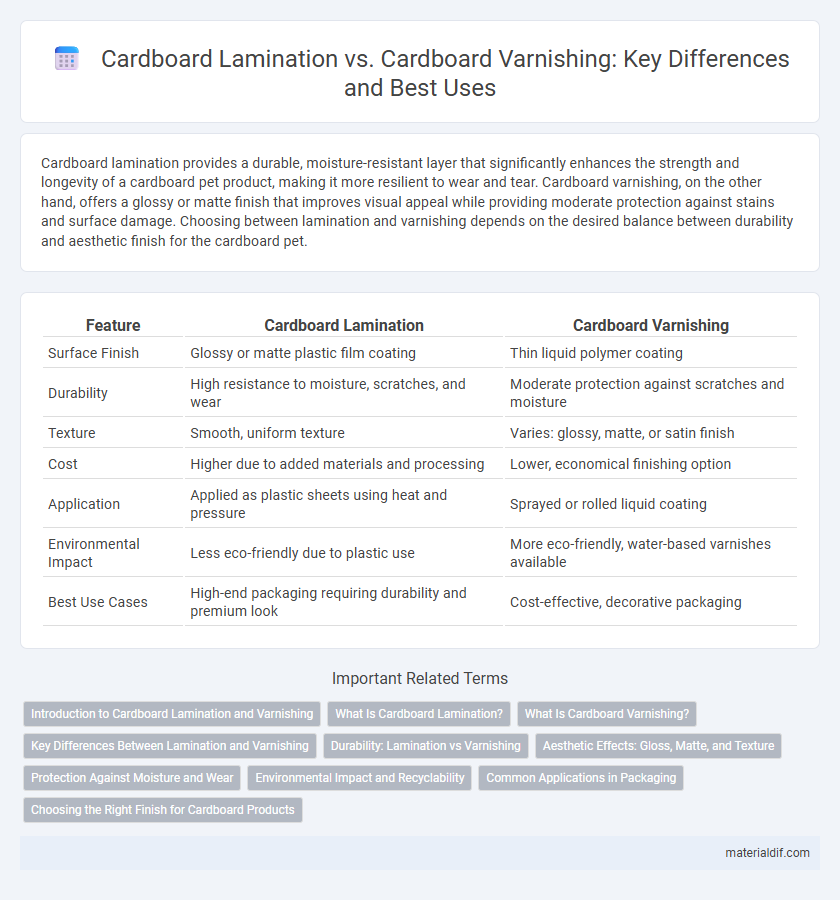

Cardboard lamination provides a durable, moisture-resistant layer that significantly enhances the strength and longevity of a cardboard pet product, making it more resilient to wear and tear. Cardboard varnishing, on the other hand, offers a glossy or matte finish that improves visual appeal while providing moderate protection against stains and surface damage. Choosing between lamination and varnishing depends on the desired balance between durability and aesthetic finish for the cardboard pet.

Table of Comparison

| Feature | Cardboard Lamination | Cardboard Varnishing |

|---|---|---|

| Surface Finish | Glossy or matte plastic film coating | Thin liquid polymer coating |

| Durability | High resistance to moisture, scratches, and wear | Moderate protection against scratches and moisture |

| Texture | Smooth, uniform texture | Varies: glossy, matte, or satin finish |

| Cost | Higher due to added materials and processing | Lower, economical finishing option |

| Application | Applied as plastic sheets using heat and pressure | Sprayed or rolled liquid coating |

| Environmental Impact | Less eco-friendly due to plastic use | More eco-friendly, water-based varnishes available |

| Best Use Cases | High-end packaging requiring durability and premium look | Cost-effective, decorative packaging |

Introduction to Cardboard Lamination and Varnishing

Cardboard lamination involves applying a thin plastic film to the surface, enhancing durability, moisture resistance, and providing a glossy or matte finish, which helps protect printed graphics from wear and tear. Cardboard varnishing utilizes a liquid coating applied directly to the surface, offering a protective layer that can be glossy, matte, or soft-touch, improving appearance while maintaining recyclability. Both processes serve to improve cardboard's aesthetic appeal and functional properties, with lamination offering superior moisture protection and varnishing focusing on enhanced tactile and visual effects.

What Is Cardboard Lamination?

Cardboard lamination involves applying a thin plastic film over the surface to enhance durability, water resistance, and visual appeal, making it ideal for packaging and product protection. This process creates a smooth, glossy, or matte finish that reinforces the cardboard against wear and tear, extending its lifespan. Unlike cardboard varnishing, which uses a liquid coating for shine and protection, lamination provides a more robust barrier against moisture and damage.

What Is Cardboard Varnishing?

Cardboard varnishing involves applying a clear liquid coating that enhances the surface's durability and aesthetic appeal by providing a glossy or matte finish. This process improves resistance to moisture, scratches, and dirt, making the cardboard more suitable for packaging and display purposes. Unlike lamination, varnishing maintains the cardboard's natural texture while offering a protective layer that preserves printed graphics.

Key Differences Between Lamination and Varnishing

Cardboard lamination involves applying a thin plastic film to enhance durability, water resistance, and overall protection against wear, while varnishing uses a liquid coating to provide a glossy or matte finish that enhances visual appeal without significantly improving structural strength. Laminated cardboard offers superior moisture resistance and scratch protection, making it ideal for packaging that requires extended handling or exposure to elements. Varnishing primarily improves surface aesthetics and print vibrancy but provides limited defense against physical damage compared to lamination.

Durability: Lamination vs Varnishing

Cardboard lamination offers superior durability by creating a protective plastic film that resists moisture, abrasion, and tearing, extending the lifespan of packaging and printed materials. Varnishing provides a thinner, less robust coating that enhances appearance but offers limited protection against physical damage and water exposure. For long-lasting durability, lamination is preferred over varnishing in high-wear or high-moisture environments.

Aesthetic Effects: Gloss, Matte, and Texture

Cardboard lamination offers a durable, protective layer that enhances aesthetic effects with options like glossy, matte, or textured finishes, providing a smooth and often shiny appearance that increases visual appeal. Varnishing on cardboard adds a thin coating that can range from high gloss to matte, preserving the natural texture while enhancing color vibrancy and resistance to moisture. Lamination typically results in a thicker, more uniform surface, whereas varnishing retains more of the cardboard's original tactile feel, making it ideal for projects emphasizing texture alongside visual effects.

Protection Against Moisture and Wear

Cardboard lamination provides a durable plastic coating that offers superior protection against moisture and abrasion, making it ideal for packaging that requires water resistance and enhanced longevity. Cardboard varnishing applies a thin, glossy or matte finish that primarily enhances appearance and provides moderate resistance to scratches and wear but offers limited moisture protection. Selecting lamination ensures better defense against water damage and surface wear compared to varnishing, which is more suited for aesthetic improvements with minimal protective properties.

Environmental Impact and Recyclability

Cardboard lamination involves applying a plastic film, which significantly reduces recyclability and increases environmental waste due to its non-biodegradable nature. In contrast, cardboard varnishing uses water-based or UV varnishes that maintain higher recyclability and lower ecological footprint by facilitating easier fiber recovery during recycling. Choosing varnishing over lamination supports sustainable packaging practices and reduces landfill contributions.

Common Applications in Packaging

Cardboard lamination enhances durability and moisture resistance, making it ideal for packaging products like food containers, electronics, and cosmetics that require protection during shipping and storage. Varnishing provides a glossy or matte finish to cardboard surfaces, commonly used in retail packaging to improve visual appeal and brand presentation on items such as luxury boxes and promotional materials. Both treatments extend cardboard functionality, with lamination focusing on protection and varnishing emphasizing aesthetic value in packaging applications.

Choosing the Right Finish for Cardboard Products

Cardboard lamination offers a durable, water-resistant finish that enhances structural strength and protects against wear and tear, making it ideal for packaging that requires longevity. Cardboard varnishing provides a glossy or matte surface that enhances visual appeal without significantly increasing thickness or rigidity, suitable for marketing materials and lightweight packaging. Selecting the right finish depends on product usage, with lamination recommended for moisture exposure and durability, while varnishing suits aesthetic enhancement and cost-effectiveness.

Cardboard lamination vs Cardboard varnishing Infographic

materialdif.com

materialdif.com