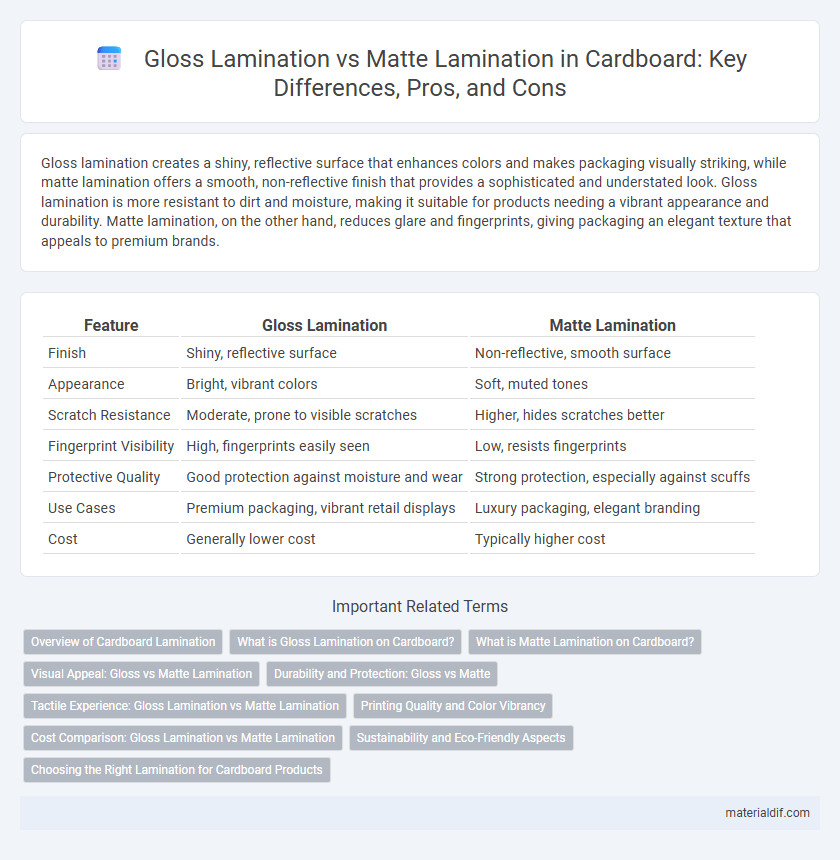

Gloss lamination creates a shiny, reflective surface that enhances colors and makes packaging visually striking, while matte lamination offers a smooth, non-reflective finish that provides a sophisticated and understated look. Gloss lamination is more resistant to dirt and moisture, making it suitable for products needing a vibrant appearance and durability. Matte lamination, on the other hand, reduces glare and fingerprints, giving packaging an elegant texture that appeals to premium brands.

Table of Comparison

| Feature | Gloss Lamination | Matte Lamination |

|---|---|---|

| Finish | Shiny, reflective surface | Non-reflective, smooth surface |

| Appearance | Bright, vibrant colors | Soft, muted tones |

| Scratch Resistance | Moderate, prone to visible scratches | Higher, hides scratches better |

| Fingerprint Visibility | High, fingerprints easily seen | Low, resists fingerprints |

| Protective Quality | Good protection against moisture and wear | Strong protection, especially against scuffs |

| Use Cases | Premium packaging, vibrant retail displays | Luxury packaging, elegant branding |

| Cost | Generally lower cost | Typically higher cost |

Overview of Cardboard Lamination

Gloss lamination on cardboard provides a shiny, reflective surface that enhances color vibrancy and offers excellent protection against moisture and scratches. Matte lamination creates a non-reflective, smooth finish that reduces glare and lends a sophisticated, muted appearance while maintaining durability. Both lamination types increase the lifespan of cardboard packaging by adding a layer of resistance to wear and environmental factors.

What is Gloss Lamination on Cardboard?

Gloss lamination on cardboard is a thin, transparent plastic film applied to the surface, providing a shiny, reflective finish that enhances color vibrancy and visual appeal. This coating offers increased durability, water resistance, and protection against scratches, making it ideal for packaging and promotional materials. Gloss lamination also improves the cardboard's overall strength while highlighting printed details for a striking, professional appearance.

What is Matte Lamination on Cardboard?

Matte lamination on cardboard provides a non-reflective, smooth finish that enhances the tactile experience and reduces glare, making printed designs easy to read under various lighting conditions. This lamination technique offers excellent protection against scratches, moisture, and general wear while maintaining an elegant, understated look. Matte lamination is commonly used for premium packaging, luxury goods, and promotional materials where a sophisticated appearance and durability are essential.

Visual Appeal: Gloss vs Matte Lamination

Gloss lamination enhances cardboard packaging with a shiny, reflective surface that intensifies colors and highlights, making graphics appear more vibrant and eye-catching. Matte lamination provides a smooth, non-reflective finish that creates a subtle, sophisticated look by reducing glare and fingerprints. Choosing between gloss and matte lamination depends on the desired visual impact, with gloss offering high shine and vibrancy while matte delivers elegance and a soft touch.

Durability and Protection: Gloss vs Matte

Gloss lamination offers superior durability by providing a high-gloss, moisture-resistant coating that protects cardboard from scratches, spills, and dirt, making it ideal for items requiring enhanced protection. Matte lamination, while less reflective, provides a strong protective layer that resists fingerprints and glare, maintaining a clean appearance with moderate durability suitable for everyday handling. Both laminations enhance cardboard's overall resilience, but gloss excels in moisture resistance and sheen, whereas matte optimizes anti-glare and subtle durability.

Tactile Experience: Gloss Lamination vs Matte Lamination

Gloss lamination offers a smooth, shiny surface that enhances color vibrancy and provides a slick tactile experience, making cardboard feel polished and reflective. Matte lamination delivers a soft, non-reflective finish with a subtle texture that reduces glare and imparts a sophisticated, tactile grip. Choosing between gloss and matte lamination on cardboard depends on the desired sensory interaction and visual appeal, emphasizing either a sleek or tactile matte feel.

Printing Quality and Color Vibrancy

Gloss lamination enhances printing quality by providing a smooth, shiny surface that intensifies color vibrancy and sharpness, making images appear more vivid and eye-catching on cardboard. Matte lamination offers a non-reflective finish with a subtle texture that reduces glare, providing a softer, more elegant look but slightly muting colors compared to gloss. Choosing between gloss and matte lamination depends on the desired visual impact, with gloss delivering brighter colors and sharper details and matte emphasizing a muted, sophisticated aesthetic on printed cardboard.

Cost Comparison: Gloss Lamination vs Matte Lamination

Gloss lamination typically costs more than matte lamination due to the higher-quality finish and added sheen that enhances visual appeal, making it ideal for premium packaging. Matte lamination reduces glare and fingerprints, offering a smooth, elegant look at a lower production cost, preferred for eco-friendly and understated designs. Budget considerations favor matte lamination for large-volume projects, while gloss lamination suits products needing attention-grabbing packaging despite higher expenses.

Sustainability and Eco-Friendly Aspects

Gloss lamination on cardboard provides a shiny finish but often uses non-biodegradable polymers that hinder recycling and increase environmental impact. Matte lamination, typically water-based and biodegradable, offers a more sustainable alternative by enhancing recyclability and reducing chemical waste. Choosing matte lamination supports eco-friendly packaging initiatives and aligns with circular economy practices.

Choosing the Right Lamination for Cardboard Products

Gloss lamination enhances cardboard products by providing a shiny, reflective surface that boosts color vibrancy and visual appeal, making it ideal for marketing materials and packaging that require eye-catching presentation. Matte lamination offers a non-reflective, smooth finish that reduces glare and fingerprints, delivering a sophisticated, subtle look and superior durability for premium packaging and luxury goods. Selecting the right lamination depends on the desired aesthetic, functional durability, and brand positioning, with gloss suited for vibrant displays and matte preferred for elegance and practical handling.

Gloss lamination vs Matte lamination Infographic

materialdif.com

materialdif.com