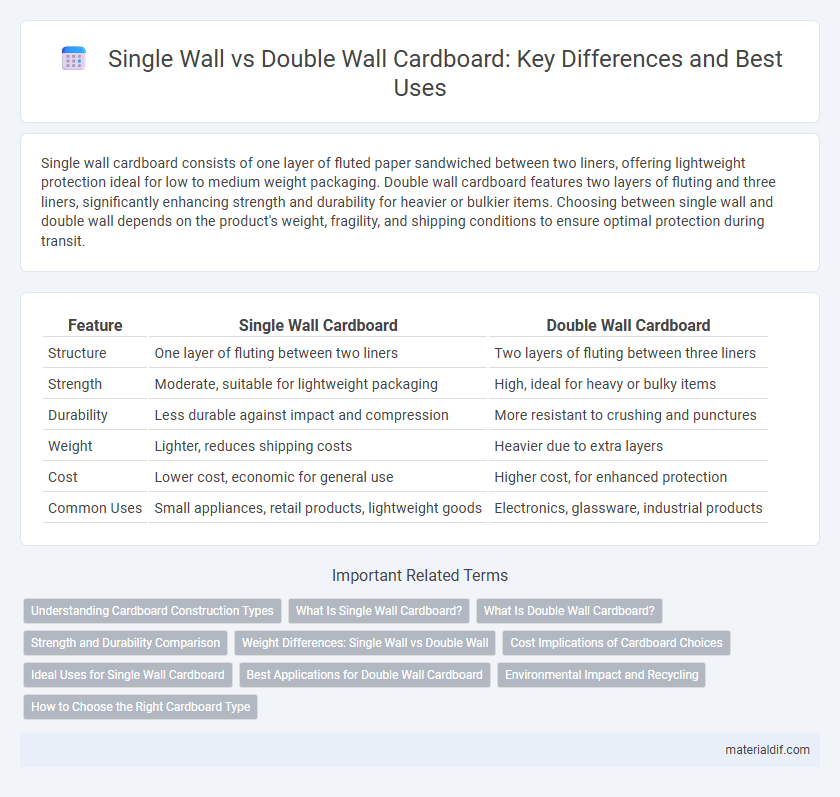

Single wall cardboard consists of one layer of fluted paper sandwiched between two liners, offering lightweight protection ideal for low to medium weight packaging. Double wall cardboard features two layers of fluting and three liners, significantly enhancing strength and durability for heavier or bulkier items. Choosing between single wall and double wall depends on the product's weight, fragility, and shipping conditions to ensure optimal protection during transit.

Table of Comparison

| Feature | Single Wall Cardboard | Double Wall Cardboard |

|---|---|---|

| Structure | One layer of fluting between two liners | Two layers of fluting between three liners |

| Strength | Moderate, suitable for lightweight packaging | High, ideal for heavy or bulky items |

| Durability | Less durable against impact and compression | More resistant to crushing and punctures |

| Weight | Lighter, reduces shipping costs | Heavier due to extra layers |

| Cost | Lower cost, economic for general use | Higher cost, for enhanced protection |

| Common Uses | Small appliances, retail products, lightweight goods | Electronics, glassware, industrial products |

Understanding Cardboard Construction Types

Single wall cardboard consists of one layer of fluted paper sandwiched between two flat linerboards, offering lightweight protection ideal for routine shipping and storage. Double wall cardboard features two layers of fluted paper between three linerboards, providing enhanced strength, superior cushioning, and increased puncture resistance suitable for heavier or more fragile items. Understanding these construction types helps select the appropriate cardboard strength for specific packaging needs, balancing cost-efficiency and durability.

What Is Single Wall Cardboard?

Single wall cardboard consists of one corrugated medium sandwiched between two flat linerboards, offering lightweight yet durable packaging solutions. It provides adequate protection for everyday items and is commonly used for shipping boxes and retail packaging. This type of cardboard balances cost-efficiency with structural strength, making it ideal for general-purpose applications.

What Is Double Wall Cardboard?

Double wall cardboard features two layers of corrugated medium sandwiched between three linerboards, offering enhanced strength and durability compared to single wall cardboard, which has only one corrugated layer and two linerboards. This construction provides superior resistance to crushing, punctures, and impacts, making double wall cardboard ideal for shipping heavy or fragile items. Its increased thickness and rigidity support better stacking strength and protection during transit, improving product safety in logistics and storage.

Strength and Durability Comparison

Single wall cardboard provides sufficient strength for lightweight packaging needs, featuring a single layer of fluted paper between two liners. Double wall cardboard offers enhanced durability and greater load-bearing capacity with two layers of fluted paper and three liners, making it ideal for heavier or more fragile items. The increased thickness and structural reinforcement of double wall cardboard result in superior resistance to punctures, crushing, and moisture compared to single wall.

Weight Differences: Single Wall vs Double Wall

Single wall cardboard typically weighs between 150 to 300 grams per square meter (GSM), making it lighter and more flexible for general packaging needs. Double wall cardboard, composed of two layers of corrugated medium, ranges from 350 to 600 GSM, providing enhanced strength and durability for heavier or more fragile items. The significant weight increase in double wall cardboard directly correlates with its improved load-bearing capacity and puncture resistance.

Cost Implications of Cardboard Choices

Single wall cardboard offers a cost-effective solution for lightweight packaging needs due to its thinner construction and lower material usage. Double wall cardboard, while more expensive, provides enhanced durability and protection, reducing potential product damage and associated costs in transit. Choosing between single wall and double wall depends on balancing upfront material expenses against long-term savings from decreased breakage and returns.

Ideal Uses for Single Wall Cardboard

Single wall cardboard is ideal for lightweight packaging such as retail boxes, cereal packaging, and shipping small electronic components, where cost efficiency and moderate protection are priorities. Its single corrugated layer provides sufficient cushioning for products with minimal fragility, making it preferred for everyday consumer goods and promotional packaging. This type of cardboard ensures easy handling and recycling, aligning with sustainable packaging solutions.

Best Applications for Double Wall Cardboard

Double wall cardboard offers enhanced durability and strength, making it ideal for shipping heavy or fragile items such as electronics, glassware, and industrial parts. Its dual layers provide superior resistance to punctures, moisture, and crushing forces, ensuring better protection during long transit periods. Industries requiring secure packaging for multiple stacking or rough handling prefer double wall cardboard for optimal safety and integrity.

Environmental Impact and Recycling

Single wall cardboard offers lightweight packaging with easier recyclability, reducing energy consumption during processing and minimizing environmental footprint. Double wall cardboard, while providing enhanced durability and protection, requires more raw materials and energy to produce, which can increase its environmental impact. Both types are widely recyclable, but efficient recycling facilities favor single wall cardboard due to its simpler fiber structure and lower contamination rates.

How to Choose the Right Cardboard Type

Single wall cardboard provides lightweight protection and is ideal for shipping small, non-fragile items, while double wall cardboard offers enhanced strength and durability, suitable for heavier or fragile products. Choosing the right cardboard type depends on the weight, fragility, and shipping conditions of the contents, as well as budget considerations. Assessing the specific requirements for protection and cost-efficiency ensures optimal package safety and material use.

Single wall vs Double wall Infographic

materialdif.com

materialdif.com