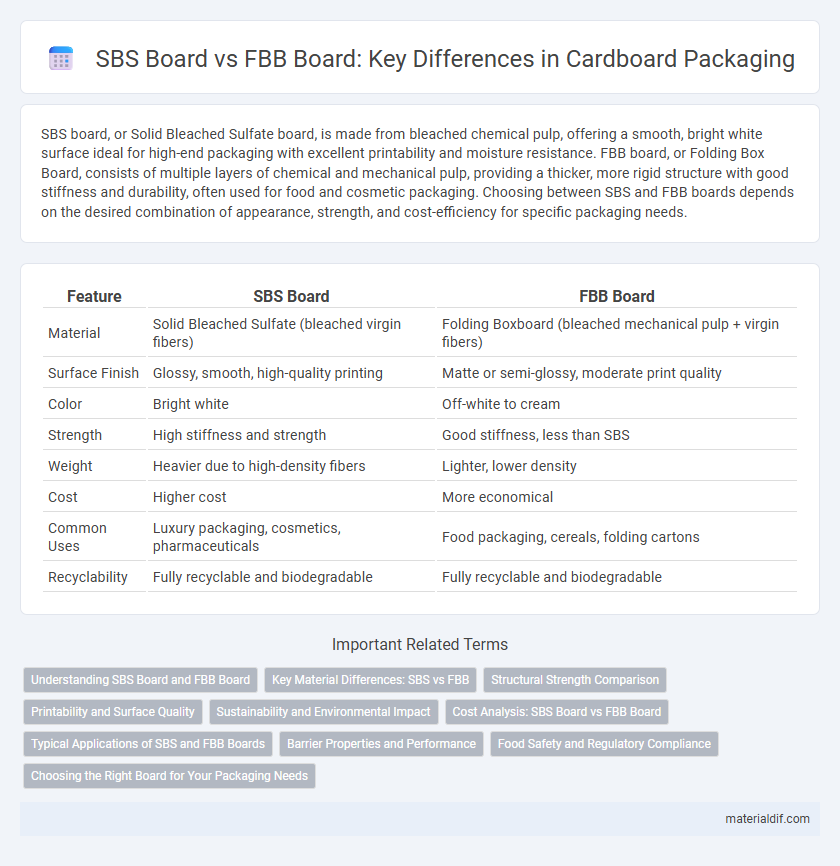

SBS board, or Solid Bleached Sulfate board, is made from bleached chemical pulp, offering a smooth, bright white surface ideal for high-end packaging with excellent printability and moisture resistance. FBB board, or Folding Box Board, consists of multiple layers of chemical and mechanical pulp, providing a thicker, more rigid structure with good stiffness and durability, often used for food and cosmetic packaging. Choosing between SBS and FBB boards depends on the desired combination of appearance, strength, and cost-efficiency for specific packaging needs.

Table of Comparison

| Feature | SBS Board | FBB Board |

|---|---|---|

| Material | Solid Bleached Sulfate (bleached virgin fibers) | Folding Boxboard (bleached mechanical pulp + virgin fibers) |

| Surface Finish | Glossy, smooth, high-quality printing | Matte or semi-glossy, moderate print quality |

| Color | Bright white | Off-white to cream |

| Strength | High stiffness and strength | Good stiffness, less than SBS |

| Weight | Heavier due to high-density fibers | Lighter, lower density |

| Cost | Higher cost | More economical |

| Common Uses | Luxury packaging, cosmetics, pharmaceuticals | Food packaging, cereals, folding cartons |

| Recyclability | Fully recyclable and biodegradable | Fully recyclable and biodegradable |

Understanding SBS Board and FBB Board

SBS board (Solid Bleached Sulfate) is a high-quality, bleached paperboard made from virgin wood fibers, known for its smooth surface and excellent printability, making it ideal for luxury packaging and food-grade applications. FBB board (Folding Box Board), also derived from virgin fibers but with a layered structure including mechanical pulp, offers superior stiffness and bulk, commonly used for folding cartons and consumer goods packaging. Understanding the differences between SBS and FBB boards is crucial for selecting the appropriate cardboard based on strength, appearance, and cost requirements in packaging solutions.

Key Material Differences: SBS vs FBB

SBS board, made from virgin fibers, offers a smooth surface and high stiffness ideal for premium packaging and printing applications, whereas FBB (Folding Box Board) combines virgin and recycled fibers, providing excellent strength and lightweight properties suited for various packaging needs. The key material difference lies in the fiber composition: SBS uses solely bleached chemical pulp ensuring superior brightness and printability, while FBB includes mechanical pulp layers that enhance rigidity and bulk but can reduce smoothness. This distinction influences their applications, with SBS preferred for luxury packaging and cosmetics, and FBB widely used in food and pharmaceutical packaging due to its balance of durability and cost-effectiveness.

Structural Strength Comparison

SBS board, composed mainly of virgin fibers, offers higher structural strength and better durability compared to FBB board, which contains a significant proportion of recycled fibers. The virgin fibers in SBS enhance tensile strength and stiffness, making it ideal for packaging that requires superior resistance to bending and impact. FBB board, while more cost-effective and eco-friendly, generally exhibits lower mechanical strength, limiting its use in heavy-duty packaging applications.

Printability and Surface Quality

SBS board (Solid Bleached Sulfate) offers superior printability due to its smooth, high-quality cellulose surface, enabling vibrant color reproduction and sharp detail. FBB board (Folding Boxboard) provides a more natural, fibrous texture which may result in less precise print finishes but offers better absorption for certain inks. Surface quality of SBS is consistently uniform, making it ideal for premium packaging, whereas FBB's multilayer structure can cause slight variations impacting print clarity.

Sustainability and Environmental Impact

SBS board, made from virgin fibers, offers higher strength and print quality but has a larger carbon footprint due to intensive resource consumption and energy use during production. FBB board, composed mainly of recycled fibers, significantly reduces deforestation and waste, promoting a circular economy with lower greenhouse gas emissions. Choosing FBB board supports sustainable packaging solutions by minimizing environmental impact through resource efficiency and recyclability.

Cost Analysis: SBS Board vs FBB Board

SBS board generally costs more than FBB board due to its higher quality virgin fibers, which provide superior strength and printability. FBB board, made primarily from recycled fibers, offers a more budget-friendly option suitable for less demanding packaging needs. Cost analysis shows businesses opting for FBB when minimizing expenses is critical, while SBS is preferred for premium packaging that demands durability and aesthetic appeal.

Typical Applications of SBS and FBB Boards

SBS board (Solid Bleached Sulfate) is commonly used in high-end packaging for cosmetics, pharmaceuticals, and food products due to its superior whiteness, smooth surface, and excellent printability. FBB board (Folding Box Board) is preferred for packaging in cereals, frozen foods, and non-food items because of its cost-effectiveness, stiffness, and good folding properties. Both SBS and FBB boards are essential in the packaging industry, with SBS offering premium aesthetics and FBB providing structural strength for various applications.

Barrier Properties and Performance

SBS board (Solid Bleached Sulfate) offers superior barrier properties compared to FBB board (Folding Boxboard), providing enhanced moisture, grease, and odor resistance ideal for food packaging. The solid bleached sulfate structure ensures high purity and strength, making SBS more durable and visually appealing for premium applications. FBB board, while cost-effective and versatile, has lower barrier performance and is better suited for dry goods or secondary packaging needs.

Food Safety and Regulatory Compliance

SBS board (Solid Bleached Sulfate) offers superior purity and is FDA-compliant, making it ideal for food packaging requiring direct contact with food. FBB board (Folding Boxboard) contains unbleached fibers and limited barriers, often necessitating additional coatings to meet food safety regulations. Both boards must adhere to regulations like FDA 21 CFR and EU Framework Regulation 1935/2004, but SBS inherently provides better compliance for hygiene and chemical migration standards.

Choosing the Right Board for Your Packaging Needs

SBS board, made from virgin fibers, offers superior strength, smoothness, and excellent printability, making it ideal for luxury packaging and high-quality graphics. FBB board, composed of recycled fibers, provides a sturdy and cost-effective option suitable for secondary packaging or products with less visual emphasis. Selecting between SBS and FBB depends on the packaging requirements, budget constraints, and desired aesthetic impact.

SBS board vs FBB board Infographic

materialdif.com

materialdif.com