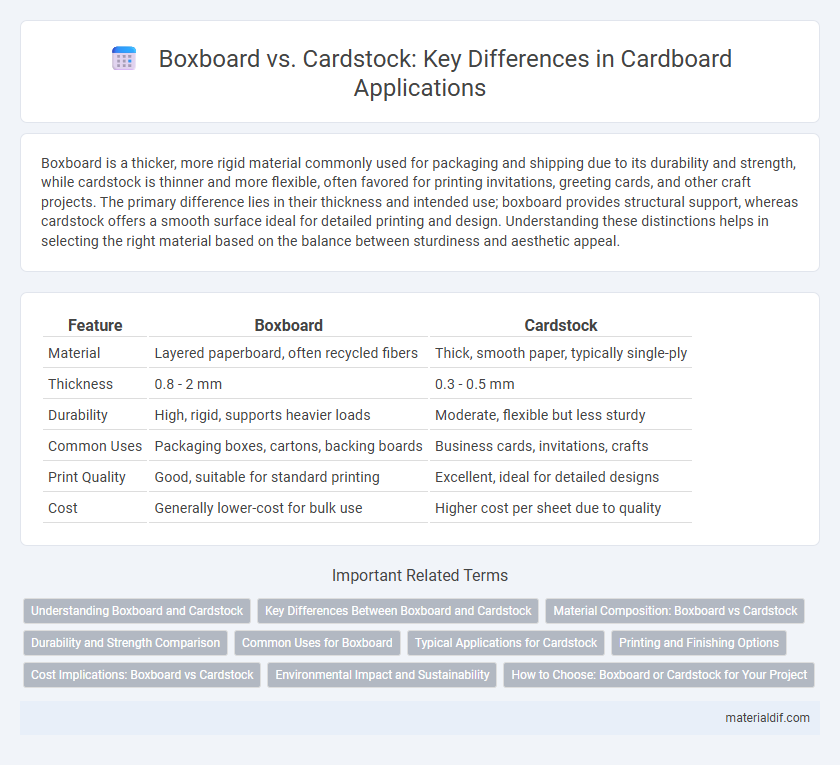

Boxboard is a thicker, more rigid material commonly used for packaging and shipping due to its durability and strength, while cardstock is thinner and more flexible, often favored for printing invitations, greeting cards, and other craft projects. The primary difference lies in their thickness and intended use; boxboard provides structural support, whereas cardstock offers a smooth surface ideal for detailed printing and design. Understanding these distinctions helps in selecting the right material based on the balance between sturdiness and aesthetic appeal.

Table of Comparison

| Feature | Boxboard | Cardstock |

|---|---|---|

| Material | Layered paperboard, often recycled fibers | Thick, smooth paper, typically single-ply |

| Thickness | 0.8 - 2 mm | 0.3 - 0.5 mm |

| Durability | High, rigid, supports heavier loads | Moderate, flexible but less sturdy |

| Common Uses | Packaging boxes, cartons, backing boards | Business cards, invitations, crafts |

| Print Quality | Good, suitable for standard printing | Excellent, ideal for detailed designs |

| Cost | Generally lower-cost for bulk use | Higher cost per sheet due to quality |

Understanding Boxboard and Cardstock

Boxboard and cardstock are both paper-based materials but differ significantly in composition and application. Boxboard is a thicker, multi-ply paperboard often used for packaging due to its durability and rigidity, while cardstock is generally thinner, more flexible, and commonly utilized for crafting and printing projects. Understanding the weight, thickness, and intended use of each material helps in selecting the right option for specific packaging or design needs.

Key Differences Between Boxboard and Cardstock

Boxboard is a lightweight, rigid paperboard typically made from layers of cellulose fibers, offering excellent durability and protection for packaging applications. Cardstock is thicker and more flexible than regular paper but generally less sturdy than boxboard, making it ideal for crafting, invitations, and business cards. The key differences lie in their weight, thickness, and strength, with boxboard designed for structural support and cardstock favored for versatility and printability.

Material Composition: Boxboard vs Cardstock

Boxboard is typically made from multiple layers of recycled paper pulp, resulting in a thicker, more rigid structure suited for packaging and shipping. Cardstock, on the other hand, is usually composed of a single layer of high-quality, dense paper fibers, offering smoother surface and flexibility ideal for printing and crafting. The material composition differences influence durability, thickness, and application suitability between boxboard and cardstock.

Durability and Strength Comparison

Boxboard offers superior durability and strength compared to cardstock, making it ideal for heavier packaging and structural applications. Its multi-layered composition enhances resistance to bending and crushing, whereas cardstock, being thinner and less dense, suits lighter uses like invitations and greeting cards. The rigidity of boxboard supports better protection of contents during shipping and handling.

Common Uses for Boxboard

Boxboard is widely used in packaging for consumer goods such as cereals, pharmaceuticals, and cosmetics due to its lightweight yet sturdy structure. Its smooth surface and excellent printability make it ideal for high-quality graphics and branding on retail packaging. Industries prefer boxboard for food containers and folding cartons because it provides a cost-effective, recyclable option that protects products while maintaining visual appeal.

Typical Applications for Cardstock

Cardstock is commonly used for business cards, postcards, and invitations due to its smooth texture and durability. Unlike boxboard, which is favored for packaging and structural applications, cardstock excels in printing quality and aesthetic appeal. Its thickness ranges from 50 to 110 lb cover stock, making it ideal for projects requiring stiffness without excessive bulk.

Printing and Finishing Options

Boxboard offers superior printing capabilities due to its smooth surface and durability, making it ideal for high-quality graphics and detailed designs. Cardstock, while less rigid, supports a variety of finishes like matte, glossy, and textured, providing versatile options for creative projects. Printing techniques such as offset, digital, and screen printing are compatible with both materials, but boxboard's structure enables better color accuracy and finish longevity.

Cost Implications: Boxboard vs Cardstock

Boxboard generally incurs higher manufacturing costs due to its thicker layers and enhanced durability compared to cardstock, which is lighter and more economical for mass production. Cardstock's affordability makes it a preferred choice for projects requiring cost-effective, versatile paper stock, although it sacrifices some strength and rigidity. Budget-sensitive packaging or crafting decisions often hinge on balancing boxboard's premium price against cardstock's cost efficiencies.

Environmental Impact and Sustainability

Boxboard generally has a lower environmental impact than cardstock due to its higher recycled fiber content and better recyclability in existing waste management systems. Cardstock often requires more virgin fibers and chemical treatments, resulting in increased resource consumption and carbon emissions during production. Sustainable packaging choices favor boxboard for its circular lifecycle benefits, including biodegradability and energy-efficient manufacturing processes.

How to Choose: Boxboard or Cardstock for Your Project

Choosing between boxboard and cardstock depends on the project's durability and structure requirements; boxboard offers sturdier, thicker material suitable for packaging and cartons, while cardstock provides a lighter, more flexible option ideal for invitations and greeting cards. Consider the weight and finish--boxboard typically ranges from 200 to 400 gsm, offering rigidity and protection, whereas cardstock often falls between 150 to 300 gsm with a smoother surface for detailed prints. Assess the project's functional needs and aesthetic preferences to select the appropriate material for optimal performance and visual appeal.

Boxboard vs Cardstock Infographic

materialdif.com

materialdif.com