Microflute cardboard features smaller, tighter flutes that provide a smoother surface ideal for detailed printing and enhanced rigidity, making it suitable for lightweight packaging. Regular flute cardboard has larger, more widely spaced flutes, offering greater cushioning and impact resistance, which is preferred for heavier, more protective packaging needs. Choosing between microflute and regular flute depends on the balance required between print quality and structural protection.

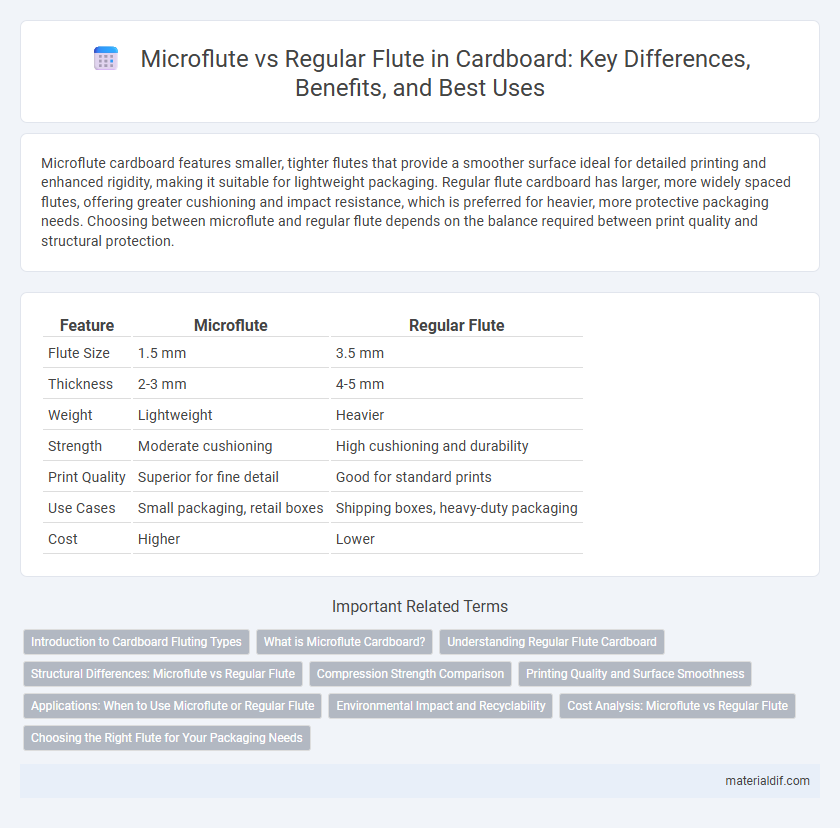

Table of Comparison

| Feature | Microflute | Regular Flute |

|---|---|---|

| Flute Size | 1.5 mm | 3.5 mm |

| Thickness | 2-3 mm | 4-5 mm |

| Weight | Lightweight | Heavier |

| Strength | Moderate cushioning | High cushioning and durability |

| Print Quality | Superior for fine detail | Good for standard prints |

| Use Cases | Small packaging, retail boxes | Shipping boxes, heavy-duty packaging |

| Cost | Higher | Lower |

Introduction to Cardboard Fluting Types

Microflute cardboard features smaller, tightly spaced flutes measuring about 1/16 inch, offering superior crush resistance and a smooth surface ideal for high-quality printing and lightweight packaging. Regular flute cardboard, typically with A, B, C, or E flute types ranging from 1/8 to 1/16 inch flute height, provides greater cushioning and rigidity suited for heavier or fragile items. Selecting the appropriate flute type balances protection, printability, and cost based on specific packaging requirements.

What is Microflute Cardboard?

Microflute cardboard features a smaller flute size, typically around 1.5 mm, compared to the standard 3-4 mm flutes in regular cardboard, offering enhanced cushioning and a smoother surface ideal for printing. This type of board provides superior rigidity and improved resistance to compression, making it suitable for delicate packaging and high-quality graphics. Microflute is commonly used in retail packaging, point-of-purchase displays, and protective inserts where lightweight strength and fine detail are essential.

Understanding Regular Flute Cardboard

Regular flute cardboard features a thicker flute size, typically around 3.2mm, providing increased rigidity and superior protection for heavy or bulky items. This flute type offers enhanced stacking strength and cushioning, making it ideal for industrial packaging and shipping applications requiring durable support. The even surface facilitates printing and graphics, improving branding opportunities on packaging materials.

Structural Differences: Microflute vs Regular Flute

Microflute cardboard features a flute height of approximately 1.5 mm, offering a finer and more compact corrugation compared to regular flute's typical height of 3 to 5 mm. This structural difference provides microflute with enhanced smoothness and print quality, making it ideal for detailed graphics and packaging requiring aesthetic precision. Regular flute delivers superior cushioning and strength due to its larger flute size, making it well-suited for heavy-duty packaging and protective applications.

Compression Strength Comparison

Microflute cardboard offers superior compression strength compared to regular flute, making it ideal for packaging items that require enhanced protection during shipping. The smaller flute size in microflute increases the density of the material, resulting in better resistance to crushing forces. This difference in compression strength helps prevent product damage and maintains the integrity of the packaging under heavy stacking conditions.

Printing Quality and Surface Smoothness

Microflute cardboard offers superior printing quality due to its finer flute structure, which creates a smoother and more uniform surface ideal for high-resolution graphics and detailed designs. In contrast, regular flute cardboard, with larger and more pronounced flutes, tends to produce a rougher surface that can result in less sharp print images and reduced visual clarity. The enhanced surface smoothness of microflute enables vibrant color replication and precision in packaging aesthetics, making it a preferred choice for premium branding.

Applications: When to Use Microflute or Regular Flute

Microflute cardboard, with its thinner profile and finer flute structure, is ideal for packaging small, lightweight products such as cosmetics, electronics, and retail displays that require a smooth surface for high-quality printing. Regular flute cardboard, featuring thicker and more durable flutes like B-flute or C-flute, provides superior cushioning and protection, making it suitable for shipping heavier items, fragile goods, and industrial packaging. Selecting microflute or regular flute depends on the balance between print quality, product protection, and the specific demands of the packaging application.

Environmental Impact and Recyclability

Microflute cardboard, with its thinner fluting layer compared to regular flute, uses less raw material, reducing environmental impact by minimizing resource consumption and waste. Its smaller flute size enhances recyclability by facilitating easier fiber separation during recycling processes, leading to higher-quality recycled pulp. Regular flute cardboard, while offering stronger structural support, typically requires more material and energy to produce and recycle, resulting in a larger ecological footprint.

Cost Analysis: Microflute vs Regular Flute

Microflute cardboard typically presents a cost-effective option compared to regular flute due to its thinner profile, requiring less raw material and reducing shipping expenses. The price per square meter of microflute is generally lower, but its durability and protective capabilities may necessitate additional cushioning or layered packaging, potentially offsetting initial savings. Evaluating total packaging costs, including material, transport, and performance requirements, is crucial for selecting between microflute and regular flute options.

Choosing the Right Flute for Your Packaging Needs

Microflute cardboard offers a thinner profile with excellent printability and smoother surface, ideal for retail packaging requiring high-quality graphics and lightweight protection. Regular flute cardboard, available in sizes like A, B, C, E, and F flutes, provides superior cushioning and stacking strength for shipping boxes and heavy-duty applications. Selecting the right flute depends on balancing product fragility, weight, and visual presentation to optimize packaging efficiency and cost-effectiveness.

Microflute vs Regular flute Infographic

materialdif.com

materialdif.com