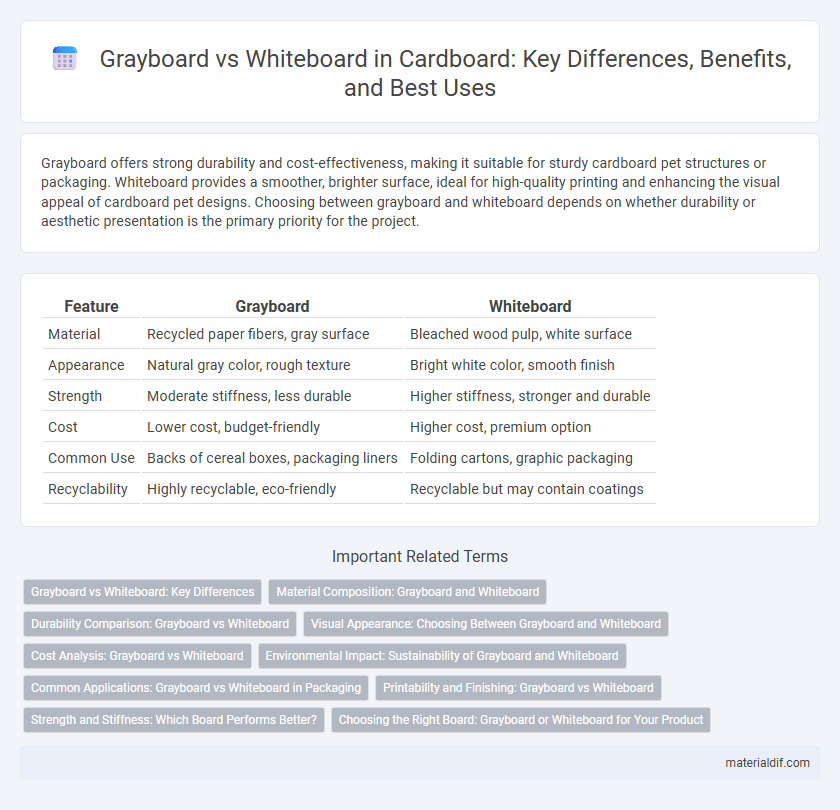

Grayboard offers strong durability and cost-effectiveness, making it suitable for sturdy cardboard pet structures or packaging. Whiteboard provides a smoother, brighter surface, ideal for high-quality printing and enhancing the visual appeal of cardboard pet designs. Choosing between grayboard and whiteboard depends on whether durability or aesthetic presentation is the primary priority for the project.

Table of Comparison

| Feature | Grayboard | Whiteboard |

|---|---|---|

| Material | Recycled paper fibers, gray surface | Bleached wood pulp, white surface |

| Appearance | Natural gray color, rough texture | Bright white color, smooth finish |

| Strength | Moderate stiffness, less durable | Higher stiffness, stronger and durable |

| Cost | Lower cost, budget-friendly | Higher cost, premium option |

| Common Use | Backs of cereal boxes, packaging liners | Folding cartons, graphic packaging |

| Recyclability | Highly recyclable, eco-friendly | Recyclable but may contain coatings |

Grayboard vs Whiteboard: Key Differences

Grayboard features a recycled fiber composition that offers durability and cost-efficiency, making it ideal for backing and packaging applications. Whiteboard, coated with a bright white clay surface, provides a smooth, printable finish preferred for high-quality graphics and retail packaging. The key differences lie in appearance, surface treatment, and intended use, with grayboard suited for structural support and whiteboard for aesthetic presentation.

Material Composition: Grayboard and Whiteboard

Grayboard is primarily composed of recycled cardboard fibers, resulting in a dense and rigid material often used for backing in packaging and bookbinding. Whiteboard typically features a base layer of bleached pulp, coated with a smooth, white surface that allows for ink adhesion and easy writing or printing. The difference in material composition impacts the appearance, durability, and applications of each board type.

Durability Comparison: Grayboard vs Whiteboard

Grayboard typically offers higher durability compared to whiteboard due to its thicker, denser composition, making it more resistant to bending and crushing in packaging applications. Whiteboard, while providing a smoother and cleaner printing surface, is generally less robust and more susceptible to moisture damage and surface wear. Choosing grayboard enhances structural strength in heavy-duty packaging, whereas whiteboard favors aesthetic appeal with moderate durability.

Visual Appearance: Choosing Between Grayboard and Whiteboard

Grayboard features a dull, matte gray finish that is ideal for eco-friendly packaging where aesthetics are less critical, while whiteboard offers a bright, clean surface perfect for high-visibility branding and retail displays. The smooth, white surface of whiteboard enhances print quality and color vibrancy, making it the preferred choice for premium packaging and marketing materials. Grayboard's unbleached appearance provides a natural look that appeals to sustainable product lines but offers limited visual impact compared to the polished finish of whiteboard.

Cost Analysis: Grayboard vs Whiteboard

Grayboard typically costs 20-30% less than whiteboard due to its recycled fiber content and lower processing expenses. Whiteboard's higher price reflects its premium bleached surface, offering superior print quality and brightness for packaging and printing needs. Cost analysis favors grayboard for budget-sensitive projects, while whiteboard justifies its cost through enhanced aesthetic appeal and durability.

Environmental Impact: Sustainability of Grayboard and Whiteboard

Grayboard, often made from recycled paper fibers, offers significant environmental benefits due to its high recyclability and lower energy consumption during production. Whiteboard typically requires additional chemical treatments and coatings, making it less eco-friendly and harder to recycle compared to grayboard. Choosing grayboard supports sustainability efforts by reducing waste and promoting the circular economy in packaging materials.

Common Applications: Grayboard vs Whiteboard in Packaging

Grayboard is commonly used in packaging for rigid boxes, backing boards, and structural components due to its cost-effectiveness and strength, making it ideal for shipping and display items. Whiteboard, with its smooth, printable surface, is favored in retail packaging, cosmetic boxes, and premium product displays, offering superior print quality and aesthetics. Both materials serve distinct roles in packaging, with grayboard providing durability and whiteboard enhancing visual appeal.

Printability and Finishing: Grayboard vs Whiteboard

Grayboard offers a dense, recycled fiber composition ideal for rigid backing but provides limited printability due to its rough, uncoated surface, resulting in muted colors and less sharp graphics. Whiteboard features a smooth, coated surface that enables vibrant, high-resolution printing with excellent ink adhesion, making it preferred for visually impactful packaging and displays. In terms of finishing, whiteboard supports diverse treatments like glossy lamination and UV coating, enhancing aesthetic appeal, whereas grayboard is typically reserved for structural reinforcement with minimal finishing options.

Strength and Stiffness: Which Board Performs Better?

Grayboard typically offers superior strength and stiffness due to its dense, recycled fiber composition, making it ideal for heavy-duty packaging and structural applications. Whiteboard, while providing a smoother surface and better printability, generally has lower stiffness and is less resistant to bending under pressure. For projects requiring maximum durability and rigidity, grayboard consistently outperforms whiteboard in mechanical strength and load-bearing capacity.

Choosing the Right Board: Grayboard or Whiteboard for Your Product

Grayboard offers superior strength and cost-effectiveness, making it ideal for packaging requiring durability and protection during shipping. Whiteboard provides a smooth, printable surface perfect for high-quality graphics and branding, enhancing product appeal on retail shelves. Selecting between grayboard and whiteboard depends on balancing functional requirements with visual presentation to meet specific packaging goals.

Grayboard vs Whiteboard Infographic

materialdif.com

materialdif.com