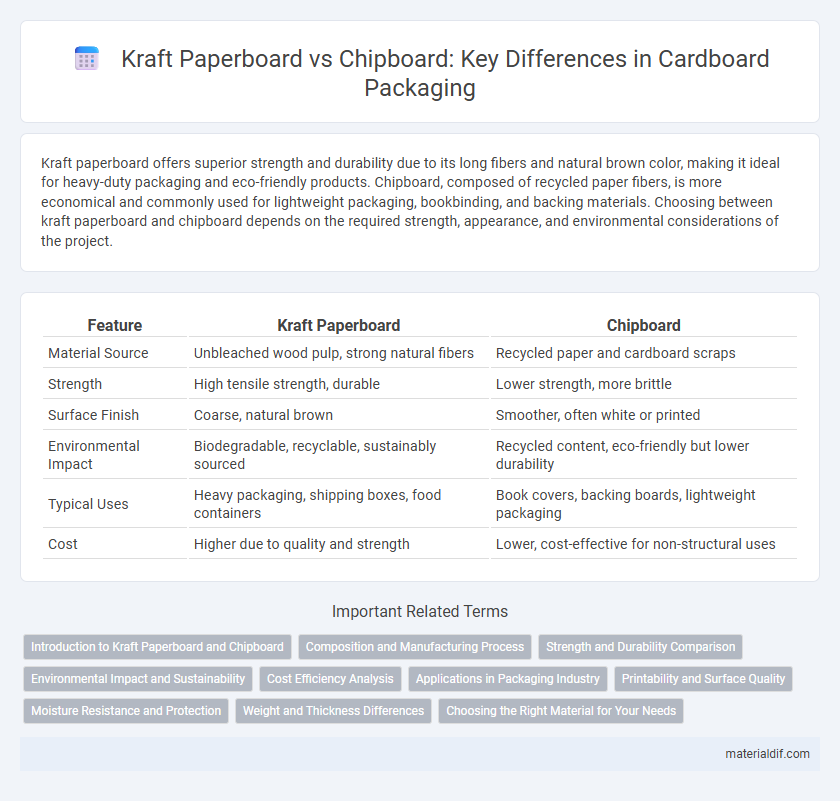

Kraft paperboard offers superior strength and durability due to its long fibers and natural brown color, making it ideal for heavy-duty packaging and eco-friendly products. Chipboard, composed of recycled paper fibers, is more economical and commonly used for lightweight packaging, bookbinding, and backing materials. Choosing between kraft paperboard and chipboard depends on the required strength, appearance, and environmental considerations of the project.

Table of Comparison

| Feature | Kraft Paperboard | Chipboard |

|---|---|---|

| Material Source | Unbleached wood pulp, strong natural fibers | Recycled paper and cardboard scraps |

| Strength | High tensile strength, durable | Lower strength, more brittle |

| Surface Finish | Coarse, natural brown | Smoother, often white or printed |

| Environmental Impact | Biodegradable, recyclable, sustainably sourced | Recycled content, eco-friendly but lower durability |

| Typical Uses | Heavy packaging, shipping boxes, food containers | Book covers, backing boards, lightweight packaging |

| Cost | Higher due to quality and strength | Lower, cost-effective for non-structural uses |

Introduction to Kraft Paperboard and Chipboard

Kraft paperboard is made from virgin wood fibers using the kraft process, offering superior strength and durability for packaging applications requiring high load-bearing capacity. Chipboard, produced from recycled paper and wood pulp, provides a cost-effective, lightweight material commonly used in packaging for less demanding structural needs. The choice between kraft paperboard and chipboard largely depends on the required strength, sustainability considerations, and budget constraints of the packaging project.

Composition and Manufacturing Process

Kraft paperboard is produced from virgin wood fibers using the kraft process, which involves chemical pulping to remove lignin and yield strong, durable fibers ideal for high-quality packaging. Chipboard, on the other hand, is made primarily from recycled paper fibers and waste paper, processed through mechanical pulping without chemical treatment, resulting in a less dense and lower-strength material. The manufacturing process of kraft paperboard ensures superior tear resistance and stiffness, while chipboard's production prioritizes cost efficiency and environmental sustainability through fiber recycling.

Strength and Durability Comparison

Kraft paperboard exhibits superior strength and durability compared to chipboard due to its dense fiber composition and higher tear resistance, making it ideal for packaging requiring robust protection. Chipboard, composed of recycled paper and lower-density fibers, offers less structural integrity and is more prone to bending and damage under weight or pressure. The tensile strength of kraft paperboard typically ranges from 150 to 200 MPa, while chipboard averages around 70 to 100 MPa, highlighting the significant difference in performance for heavy-duty applications.

Environmental Impact and Sustainability

Kraft paperboard is made from virgin wood fibers through a chemical pulping process, offering higher strength and better recyclability compared to chipboard, which primarily uses recycled paper fibers often bonded with adhesives and resins. The environmental impact of kraft paperboard is lower due to its biodegradability and efficient recycling lifecycle, whereas chipboard can contain contaminants that complicate recycling and increase landfill waste. Sustainable sourcing of kraft paperboard from responsibly managed forests supports carbon sequestration and reduces deforestation risks, making it a preferable option for eco-conscious packaging solutions.

Cost Efficiency Analysis

Kraft paperboard offers superior cost efficiency compared to chipboard due to its higher durability and recyclability, reducing long-term material replacement expenses. Chipboard, while cheaper upfront, often incurs additional costs related to lower moisture resistance and structural weakness leading to product damage or packaging failure. Businesses prioritizing cost efficiency benefit from Kraft paperboard's strength-to-weight ratio and sustainability, optimizing overall supply chain expenses.

Applications in Packaging Industry

Kraft paperboard is extensively used in packaging applications requiring high strength and durability, such as food packaging, heavy-duty cartons, and retail boxes, due to its superior tear resistance and moisture barrier properties. Chipboard, made from recycled paper fibers, is ideal for lightweight packaging solutions like folding cartons, backing for notepads, and product displays, offering cost-effectiveness and environmental benefits. Both materials serve distinct roles in the packaging industry, with kraft paperboard preferred for premium, protective packaging and chipboard favored for economical, recyclable packaging options.

Printability and Surface Quality

Kraft paperboard offers superior printability and surface quality compared to chipboard, thanks to its smooth, consistent texture and higher fiber strength. The natural brown tone of kraft paperboard allows for better ink absorption and sharper print results, making it ideal for premium packaging and branding applications. In contrast, chipboard's rougher surface and recycled content often lead to uneven ink distribution and less vibrant printing outcomes.

Moisture Resistance and Protection

Kraft paperboard offers superior moisture resistance due to its long fibers and natural lignin content, making it ideal for packaging products exposed to humidity or damp conditions. Chipboard, composed of recycled paper fibers, lacks significant moisture barrier properties and is more susceptible to water damage and structural weakening. For applications requiring enhanced protection against moisture, Kraft paperboard provides a more durable and reliable solution than chipboard.

Weight and Thickness Differences

Kraft paperboard typically exhibits higher weight and thickness compared to chipboard, making it more durable and suited for heavy-duty packaging. Kraft paperboard often weighs between 160-400 gsm with thickness ranging from 0.8 to 2 mm, while chipboard generally weighs around 200-400 gsm but remains thinner, usually from 0.5 to 1.5 mm. These differences in weight and thickness influence their respective strength, rigidity, and applications in packaging and manufacturing.

Choosing the Right Material for Your Needs

Kraft paperboard offers superior strength, durability, and resistance to moisture, making it ideal for packaging that requires protection during shipping and storage. Chipboard, composed of recycled paper fibers, provides an economical and lightweight option suitable for applications like book covers and backing materials. Selecting the right material depends on factors such as weight tolerance, environmental impact, and budget constraints to ensure optimal performance for your specific project.

Kraft paperboard vs Chipboard Infographic

materialdif.com

materialdif.com