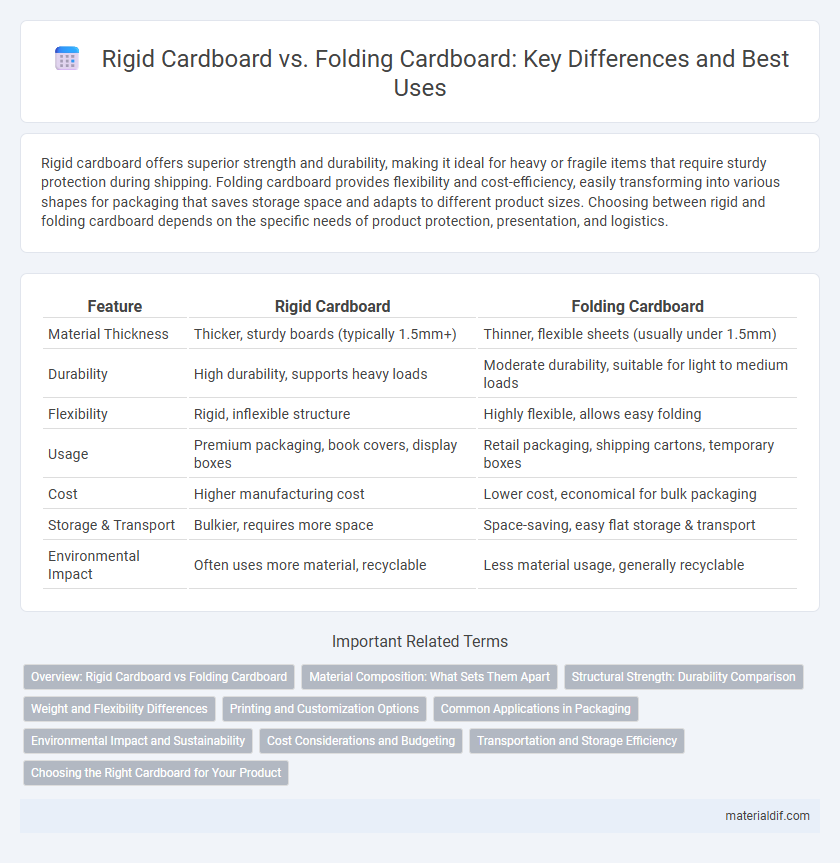

Rigid cardboard offers superior strength and durability, making it ideal for heavy or fragile items that require sturdy protection during shipping. Folding cardboard provides flexibility and cost-efficiency, easily transforming into various shapes for packaging that saves storage space and adapts to different product sizes. Choosing between rigid and folding cardboard depends on the specific needs of product protection, presentation, and logistics.

Table of Comparison

| Feature | Rigid Cardboard | Folding Cardboard |

|---|---|---|

| Material Thickness | Thicker, sturdy boards (typically 1.5mm+) | Thinner, flexible sheets (usually under 1.5mm) |

| Durability | High durability, supports heavy loads | Moderate durability, suitable for light to medium loads |

| Flexibility | Rigid, inflexible structure | Highly flexible, allows easy folding |

| Usage | Premium packaging, book covers, display boxes | Retail packaging, shipping cartons, temporary boxes |

| Cost | Higher manufacturing cost | Lower cost, economical for bulk packaging |

| Storage & Transport | Bulkier, requires more space | Space-saving, easy flat storage & transport |

| Environmental Impact | Often uses more material, recyclable | Less material usage, generally recyclable |

Overview: Rigid Cardboard vs Folding Cardboard

Rigid cardboard features thicker, denser material offering superior strength and durability, making it ideal for heavy-duty packaging and protective applications. Folding cardboard, typically made from thinner and more flexible sheets, is designed for easy folding and assembly, commonly used in retail packaging and shipping boxes. Both types serve distinct purposes based on structural needs, with rigid cardboard prioritizing robustness and folding cardboard emphasizing versatility and convenience.

Material Composition: What Sets Them Apart

Rigid cardboard, also known as chipboard, is composed of densely compressed wood fibers or recycled paper layers, offering superior thickness and sturdiness compared to folding cardboard. Folding cardboard, typically made from corrugated fiberboard or laminated layers of paperboard, is designed to be flexible and easily creaseable for folding and shaping. The key distinction lies in rigid cardboard's high-density solid structure versus folding cardboard's multi-layered, corrugated composition that balances strength with pliability.

Structural Strength: Durability Comparison

Rigid cardboard offers superior structural strength due to its dense and thick composition, making it ideal for heavy-duty packaging and long-term storage. Folding cardboard, while more flexible and suitable for easy assembly and shipping, provides less durability and can be prone to creasing or collapsing under significant weight. The enhanced thickness and stiffness of rigid cardboard ensure better protection against impacts and pressure compared to the more lightweight and foldable counterpart.

Weight and Flexibility Differences

Rigid cardboard offers greater weight and sturdiness, making it ideal for protective packaging that requires structural integrity. Folding cardboard is lighter and more flexible, allowing easy creasing and folding for efficient storage and transport. The weight difference is significant, with rigid cardboard typically heavier and less adaptable compared to the lightweight, pliable nature of folding cardboard.

Printing and Customization Options

Rigid cardboard offers superior printing quality due to its thick, sturdy surface that maintains sharp, vibrant graphics ideal for luxury packaging. Folding cardboard allows for versatile customization with various dielines and finishes, supporting intricate designs and easy assembly for mass production. Both types support advanced printing techniques such as digital, offset, and screen printing, tailored to enhance brand visibility and product presentation.

Common Applications in Packaging

Rigid cardboard is commonly used in high-end packaging for luxury goods, electronics, and cosmetics due to its thick structure providing superior protection and premium appearance. Folding cardboard is widely utilized in mass-market packaging such as cereal boxes, beverage cartons, and shipping containers because of its lightweight, cost-effectiveness, and ease of assembly. Both materials enhance product safety and branding, with rigid cardboard excelling in durability and folding cardboard offering versatility for diverse packaging formats.

Environmental Impact and Sustainability

Rigid cardboard, commonly used for premium packaging, typically requires more raw materials and energy to produce, resulting in a higher carbon footprint compared to folding cardboard. Folding cardboard, also known as corrugated board, is often more environmentally friendly due to its recyclability and lower resource consumption during manufacturing. Both materials can be sustainable if sourced from certified, managed forests and if proper recycling systems are in place.

Cost Considerations and Budgeting

Rigid cardboard typically incurs higher production costs due to its thicker, denser material and specialized manufacturing processes, making it more suitable for premium packaging with limited budget flexibility. Folding cardboard offers cost-effective advantages through its lighter weight, ease of assembly, and efficient shipping, optimizing budgets for mass production and high-volume packaging needs. Choosing between rigid and folding cardboard depends on balancing initial material expenses against long-term savings in logistics and assembly efficiency.

Transportation and Storage Efficiency

Rigid cardboard offers superior protection but requires more space during transportation and storage due to its fixed structure. Folding cardboard excels in transportation and storage efficiency by collapsing flat, minimizing volume and allowing for optimized stacking. Choosing folding cardboard significantly reduces shipping costs and maximizes warehouse space utilization.

Choosing the Right Cardboard for Your Product

Rigid cardboard offers superior strength and durability, making it ideal for high-end packaging requiring protection and premium presentation. Folding cardboard provides flexibility and cost-effectiveness, suitable for lightweight products and designs demanding easy assembly. Selecting the appropriate cardboard involves assessing product weight, protection needs, and aesthetic requirements to ensure optimal performance and customer appeal.

Rigid cardboard vs Folding cardboard Infographic

materialdif.com

materialdif.com