Peel-off liners are separate backing materials that are removed to expose the adhesive surface on cardboard, offering flexibility in application and easier customization for different uses. Integrated liners are built into the cardboard structure, providing a seamless, durable surface that enhances strength and moisture resistance without the need for additional materials. Choosing between peel-off and integrated liners depends on the specific requirements for protection, ease of use, and the intended packaging functionality.

Table of Comparison

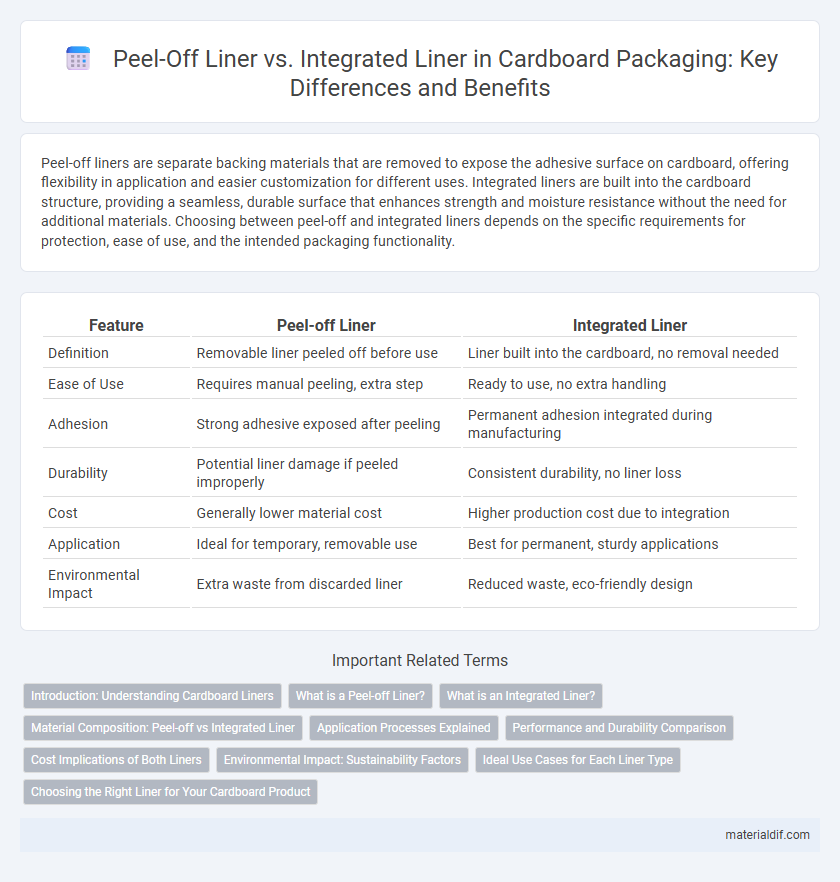

| Feature | Peel-off Liner | Integrated Liner |

|---|---|---|

| Definition | Removable liner peeled off before use | Liner built into the cardboard, no removal needed |

| Ease of Use | Requires manual peeling, extra step | Ready to use, no extra handling |

| Adhesion | Strong adhesive exposed after peeling | Permanent adhesion integrated during manufacturing |

| Durability | Potential liner damage if peeled improperly | Consistent durability, no liner loss |

| Cost | Generally lower material cost | Higher production cost due to integration |

| Application | Ideal for temporary, removable use | Best for permanent, sturdy applications |

| Environmental Impact | Extra waste from discarded liner | Reduced waste, eco-friendly design |

Introduction: Understanding Cardboard Liners

Cardboard liners serve as protective layers in packaging, with peel-off liners designed for easy removal, enhancing product accessibility and presentation. Integrated liners are permanently bonded to the cardboard, providing added strength and moisture resistance for durability during transit. Selecting the appropriate liner type depends on the packaging needs, balancing convenience with structural support.

What is a Peel-off Liner?

A peel-off liner is a removable layer of material adhered to the surface of cardboard, designed to protect adhesives or printed areas during storage and transport. This liner can be easily peeled away to reveal a clean, sticky surface, enhancing the cardboard's functionality for packaging or labeling applications. Peel-off liners are commonly used in pressure-sensitive labels, stickers, and protective films on cardboard products.

What is an Integrated Liner?

An integrated liner in cardboard packaging refers to a liner that is directly incorporated into the cardboard structure during manufacturing, creating a seamless bond between the liner and the cardboard substrate. This contrasts with peel-off liners, which are attached as a separate layer that can be removed to reveal an adhesive surface or product. Integrated liners enhance durability, improve moisture resistance, and provide a more stable surface for printing or coating applications in packaging solutions.

Material Composition: Peel-off vs Integrated Liner

Peel-off liners typically consist of silicone-coated paper or film designed for easy removal, preventing adhesive contamination during storage and handling. Integrated liners are made from materials such as coated cardboard or paperboard, bonded directly to the substrate, enhancing structural integrity and reducing waste. The choice between peel-off and integrated liners impacts recyclability, adhesive performance, and production costs in cardboard applications.

Application Processes Explained

Peel-off liners in cardboard applications simplify the adhesive exposure process by allowing users to easily remove a protective layer before bonding, making them ideal for temporary labels and packaging seals. Integrated liners consist of a built-in coating or material within the cardboard itself, enhancing durability and providing a ready-to-use adhesive surface without the need for removal, suited for permanent seals and structural supports. Both liner types influence manufacturing efficiency and end-use functionality, depending on the specific application requirements and handling procedures.

Performance and Durability Comparison

Peel-off liners offer excellent surface protection and easy removal, making them ideal for applications requiring temporary shielding, but they may peel unevenly or tear under stress. Integrated liners enhance overall structural integrity by being bonded directly to the cardboard, resulting in superior durability and resistance to wear and moisture. Performance analysis reveals that integrated liners significantly extend the lifespan of cardboard products in harsh environments, while peel-off liners prioritize convenience and repaintability.

Cost Implications of Both Liners

Peel-off liners typically incur higher material and production costs due to the additional layer and adhesive required, increasing overall packaging expenses. Integrated liners streamline manufacturing by combining the liner with the cardboard structure, reducing material usage and labor costs, resulting in a more cost-effective solution. Businesses must weigh the upfront investment against long-term savings when choosing between peel-off and integrated liners for packaging.

Environmental Impact: Sustainability Factors

Peel-off liners in cardboard packaging often generate additional waste due to the separate liner material, complicating recycling processes and increasing landfill contributions. Integrated liners minimize material use by embedding the liner within the cardboard structure, enhancing recyclability and reducing carbon footprint. Sustainable packaging trends favor integrated liners for their ability to streamline disposal and support circular economy goals.

Ideal Use Cases for Each Liner Type

Peel-off liners are ideal for applications requiring temporary protection or clean removal, such as labels, stickers, and sensitive surfaces in packaging and labeling industries. Integrated liners are best suited for permanent adhesion needs, often used in corrugated cardboard for structural reinforcement and moisture resistance. Selecting the appropriate liner enhances durability and efficiency based on the specific cardboard use case.

Choosing the Right Liner for Your Cardboard Product

Selecting the appropriate liner for your cardboard product depends on factors such as durability, application, and cost-efficiency. Peel-off liners provide easy removal and are ideal for temporary packaging or labels, while integrated liners enhance structural strength and moisture resistance for long-lasting or heavy-duty use. Consider the specific requirements of your product, including environmental exposure and handling needs, to determine the best liner type for optimal performance.

Peel-off liner vs Integrated liner Infographic

materialdif.com

materialdif.com