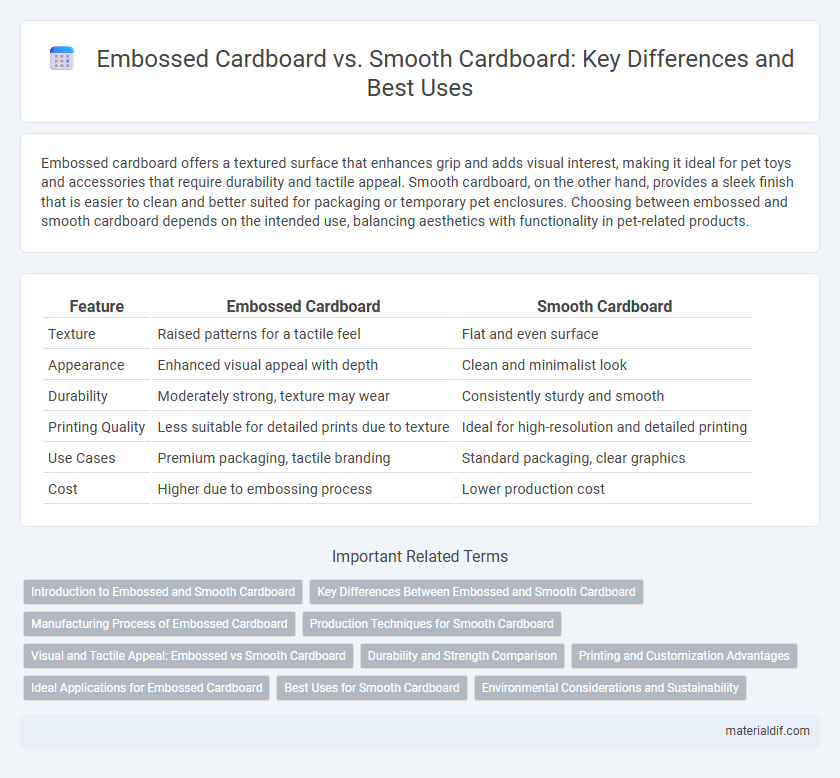

Embossed cardboard offers a textured surface that enhances grip and adds visual interest, making it ideal for pet toys and accessories that require durability and tactile appeal. Smooth cardboard, on the other hand, provides a sleek finish that is easier to clean and better suited for packaging or temporary pet enclosures. Choosing between embossed and smooth cardboard depends on the intended use, balancing aesthetics with functionality in pet-related products.

Table of Comparison

| Feature | Embossed Cardboard | Smooth Cardboard |

|---|---|---|

| Texture | Raised patterns for a tactile feel | Flat and even surface |

| Appearance | Enhanced visual appeal with depth | Clean and minimalist look |

| Durability | Moderately strong, texture may wear | Consistently sturdy and smooth |

| Printing Quality | Less suitable for detailed prints due to texture | Ideal for high-resolution and detailed printing |

| Use Cases | Premium packaging, tactile branding | Standard packaging, clear graphics |

| Cost | Higher due to embossing process | Lower production cost |

Introduction to Embossed and Smooth Cardboard

Embossed cardboard features raised patterns or textures created through a stamping process, enhancing its tactile appeal and structural integrity. Smooth cardboard has a flat, even surface ideal for printing and packaging where a sleek, professional look is essential. Both types serve distinct purposes in packaging, with embossed cardboard offering added grip and visual interest, while smooth cardboard provides a clean canvas for branding and labeling.

Key Differences Between Embossed and Smooth Cardboard

Embossed cardboard features raised patterns or textures created through a pressing process, enhancing tactile appeal and visual interest, while smooth cardboard offers a flat, uniform surface ideal for printing and packaging with clean aesthetics. Embossed cardboard provides greater rigidity and durability due to its textured surface, whereas smooth cardboard is generally more flexible and easier to fold or manipulate. These differences impact their applications, with embossed cardboard favored for premium packaging and promotional materials, and smooth cardboard commonly used in standard shipping boxes and product displays.

Manufacturing Process of Embossed Cardboard

Embossed cardboard manufacturing involves pressing patterns or textures into the surface using engraved rollers or plates during the drying stage, creating raised or recessed designs that enhance visual and tactile appeal. This process requires precise control of temperature and pressure to maintain the integrity of the cardboard fibers while producing consistent embossing effects. The added embossing step differentiates it from smooth cardboard production, which involves standard pressing and drying without textural modifications.

Production Techniques for Smooth Cardboard

Smooth cardboard production involves precise calendaring processes where the paper fibers are compressed and polished to create a uniform, flat surface ideal for high-quality printing. This technique typically includes coating the cardboard with clay or latex to enhance smoothness and durability, reducing surface roughness compared to embossed cardboard. Advanced machinery controls moisture and pressure levels meticulously, ensuring consistency in texture and strength for applications requiring fine graphic detail.

Visual and Tactile Appeal: Embossed vs Smooth Cardboard

Embossed cardboard offers a raised texture that enhances visual depth and creates a tactile experience, making packaging more engaging and premium. Smooth cardboard provides a sleek, flat surface ideal for vibrant printing and a clean, modern aesthetic with a soft touch. Choosing between embossed and smooth cardboard depends on the desired sensory impact and branding goals for packaging design.

Durability and Strength Comparison

Embossed cardboard features raised patterns that increase rigidity and resistance to compression, making it more durable than smooth cardboard in packaging and shipping applications. Smooth cardboard offers a uniform surface ideal for printing but lacks the structural reinforcement found in embossed variants. The enhanced durability and strength of embossed cardboard provide better protection against impacts and heavy loads compared to smooth cardboard.

Printing and Customization Advantages

Embossed cardboard offers enhanced texture that creates a tactile and visually appealing surface, improving brand perception through premium packaging designs. Smooth cardboard provides a uniform and flat surface ideal for high-resolution printing, ensuring sharp and vibrant graphics for precise customization. Both materials support specialized printing techniques, but embossed cardboard adds depth and dimension that elevate packaging aesthetics.

Ideal Applications for Embossed Cardboard

Embossed cardboard offers enhanced texture and visual appeal, making it ideal for luxury packaging, promotional materials, and high-end retail displays where tactile experience is crucial. Its raised patterns also provide increased grip and durability, beneficial for protective packaging and custom product boxes. Embossed cardboard's unique surface design supports branding efforts by creating a distinctive, memorable impression for consumers.

Best Uses for Smooth Cardboard

Smooth cardboard offers excellent print clarity and vibrant color reproduction, making it ideal for high-quality packaging and retail displays. Its sleek surface is perfect for branding materials, luxury product boxes, and promotional inserts where visual appeal is crucial. Smooth cardboard also provides a clean, professional finish, enhancing the overall presentation of marketing materials.

Environmental Considerations and Sustainability

Embossed cardboard typically uses more energy and resources during manufacturing due to the additional pressing and texturing processes, potentially increasing its environmental footprint compared to smooth cardboard. Smooth cardboard is generally easier to recycle and requires less processing, making it a more sustainable choice for packaging with minimal environmental impact. Companies prioritizing eco-friendly packaging often opt for smooth cardboard to reduce waste and improve recyclability in their supply chains.

Embossed cardboard vs Smooth cardboard Infographic

materialdif.com

materialdif.com