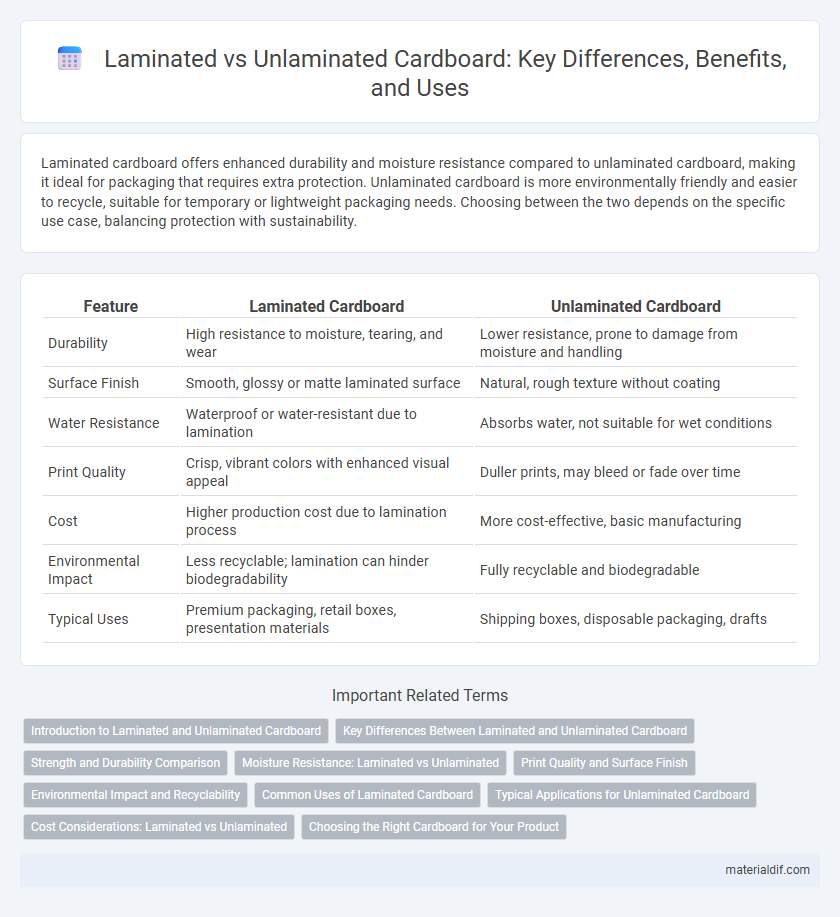

Laminated cardboard offers enhanced durability and moisture resistance compared to unlaminated cardboard, making it ideal for packaging that requires extra protection. Unlaminated cardboard is more environmentally friendly and easier to recycle, suitable for temporary or lightweight packaging needs. Choosing between the two depends on the specific use case, balancing protection with sustainability.

Table of Comparison

| Feature | Laminated Cardboard | Unlaminated Cardboard |

|---|---|---|

| Durability | High resistance to moisture, tearing, and wear | Lower resistance, prone to damage from moisture and handling |

| Surface Finish | Smooth, glossy or matte laminated surface | Natural, rough texture without coating |

| Water Resistance | Waterproof or water-resistant due to lamination | Absorbs water, not suitable for wet conditions |

| Print Quality | Crisp, vibrant colors with enhanced visual appeal | Duller prints, may bleed or fade over time |

| Cost | Higher production cost due to lamination process | More cost-effective, basic manufacturing |

| Environmental Impact | Less recyclable; lamination can hinder biodegradability | Fully recyclable and biodegradable |

| Typical Uses | Premium packaging, retail boxes, presentation materials | Shipping boxes, disposable packaging, drafts |

Introduction to Laminated and Unlaminated Cardboard

Laminated cardboard features a protective plastic or wax coating that enhances durability, water resistance, and print quality, making it ideal for packaging, especially in food and retail industries. Unlaminated cardboard lacks this coating, providing a more natural and recyclable surface suited for lightweight packaging and general shipping purposes. The choice between laminated and unlaminated cardboard depends on the balance between protection needs and environmental considerations.

Key Differences Between Laminated and Unlaminated Cardboard

Laminated cardboard features a protective plastic or wax coating that enhances durability, water resistance, and resistance to tearing compared to unlaminated cardboard, which lacks this protective layer. The lamination process adds a glossy or matte finish, improving print quality and making laminated cardboard ideal for packaging requiring a premium look or additional strength. Unlaminated cardboard remains more affordable and recyclable but is more susceptible to moisture damage, making it suitable for temporary or less demanding packaging needs.

Strength and Durability Comparison

Laminated cardboard features a protective plastic or wax coating that significantly enhances its strength and resistance to moisture, making it more durable in harsh environments compared to unlaminated cardboard. Unlaminated cardboard, composed solely of layers of paper fibers, is more prone to wear, tearing, and water damage, resulting in reduced structural integrity over time. The lamination process boosts the board's toughness and longevity, essential for packaging applications requiring extra protection and durability.

Moisture Resistance: Laminated vs Unlaminated

Laminated cardboard offers superior moisture resistance due to its protective plastic or wax coating, preventing water absorption and maintaining structural integrity in damp environments. Unlaminated cardboard lacks this barrier, making it highly susceptible to moisture damage, weakening the fibers and causing potential swelling or disintegration. This moisture protection makes laminated cardboard ideal for packaging fragile or moisture-sensitive products such as food or electronics.

Print Quality and Surface Finish

Laminated cardboard offers superior print quality with enhanced color vibrancy and sharper image details due to its protective coating that minimizes ink absorption and prevents smudging. The smooth, glossy surface finish of laminated cardboard enhances visual appeal and provides resistance to moisture and abrasion. In contrast, unlaminated cardboard has a rougher texture that can cause colors to appear dull and prints to be less defined, while its matte surface finish lacks protection, making it more susceptible to wear and damage.

Environmental Impact and Recyclability

Laminated cardboard typically contains a plastic or wax coating that enhances water resistance but significantly reduces its recyclability and increases environmental impact due to difficulties in separating materials during recycling. Unlaminated cardboard is more environmentally friendly, as it is easier to recycle and biodegrades faster, reducing landfill waste and carbon footprint. Choosing unlaminated cardboard supports a more sustainable lifecycle by facilitating efficient recycling processes and minimizing ecological harm.

Common Uses of Laminated Cardboard

Laminated cardboard is primarily used for packaging products that require enhanced durability and moisture resistance, such as food containers, retail display boxes, and protective shipping cartons. Its laminated coating provides a glossy finish that improves print quality, making it ideal for branding and advertising purposes on retail shelves. This type of cardboard also finds common applications in premium product packaging where aesthetics and protection are essential.

Typical Applications for Unlaminated Cardboard

Unlaminated cardboard is commonly used in applications requiring cost-effective packaging solutions such as shipping boxes, product dividers, and disposable trays. Its porous surface allows for easy printing and labeling, making it ideal for short-term use in retail and storage. This type of cardboard is favored in environments where moisture resistance and enhanced durability are not critical factors.

Cost Considerations: Laminated vs Unlaminated

Laminated cardboard typically incurs higher costs due to the additional materials and processes required for lamination, which enhances durability and moisture resistance. Unlaminated cardboard is more cost-effective, making it suitable for budget-conscious applications where protection against environmental factors is less critical. Choosing between laminated and unlaminated cardboard depends on balancing upfront expenses with the need for enhanced performance and longevity.

Choosing the Right Cardboard for Your Product

Laminated cardboard offers enhanced durability, moisture resistance, and a glossy finish, making it ideal for premium packaging that requires protection and an attractive appearance. Unlaminated cardboard is more cost-effective and eco-friendly, suitable for lightweight products and short-term use where breathability and recyclability are priorities. Selecting the right cardboard depends on product fragility, environmental exposure, and branding goals to optimize protection and presentation.

Laminated cardboard vs Unlaminated cardboard Infographic

materialdif.com

materialdif.com