Kraft cardboard is made from unbleached wood pulp, giving it a natural brown color and superior strength, ideal for heavy-duty packaging and eco-friendly uses. Bleached cardboard undergoes a chemical process to remove lignin, resulting in a white, smooth surface favored for high-quality printing and retail packaging. Choosing between Kraft and bleached cardboard depends on the balance between durability, appearance, and environmental considerations.

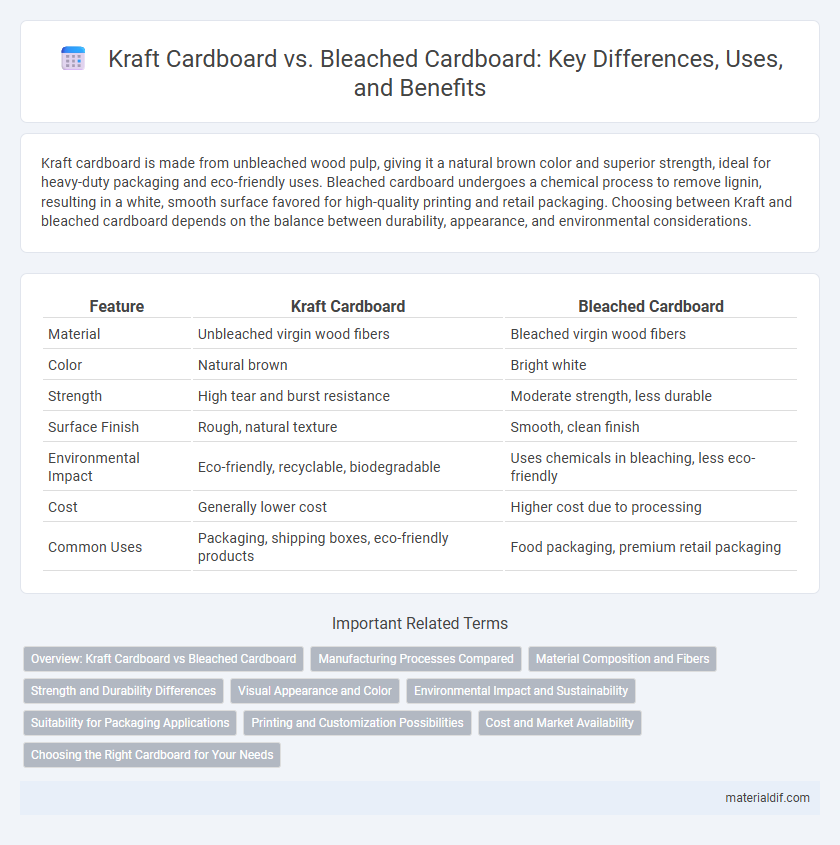

Table of Comparison

| Feature | Kraft Cardboard | Bleached Cardboard |

|---|---|---|

| Material | Unbleached virgin wood fibers | Bleached virgin wood fibers |

| Color | Natural brown | Bright white |

| Strength | High tear and burst resistance | Moderate strength, less durable |

| Surface Finish | Rough, natural texture | Smooth, clean finish |

| Environmental Impact | Eco-friendly, recyclable, biodegradable | Uses chemicals in bleaching, less eco-friendly |

| Cost | Generally lower cost | Higher cost due to processing |

| Common Uses | Packaging, shipping boxes, eco-friendly products | Food packaging, premium retail packaging |

Overview: Kraft Cardboard vs Bleached Cardboard

Kraft cardboard is made from unbleached wood pulp, providing a natural brown color and superior strength, making it ideal for heavy-duty packaging and eco-friendly applications. Bleached cardboard undergoes a chemical process to remove lignin, resulting in a white, smooth surface preferred for high-quality printing and aesthetic packaging. Both materials serve different industry needs, with kraft cardboard favored for durability and sustainability, while bleached cardboard excels in visual appeal and branding.

Manufacturing Processes Compared

Kraft cardboard is produced through the kraft process, which involves chemically treating wood pulp with sodium hydroxide and sodium sulfide to retain lignin and enhance strength, resulting in a durable, brown-hued material. Bleached cardboard undergoes an additional bleaching process using chlorine or oxygen-based compounds to remove lignin and achieve a bright white appearance, though this treatment can reduce paper fibers' strength. Manufacturing kraft cardboard prioritizes structural integrity and eco-friendliness, while bleached cardboard emphasizes aesthetic appeal for packaging requiring a cleaner, more polished look.

Material Composition and Fibers

Kraft cardboard is made from unbleached wood pulp, retaining the natural brown color and utilizing long fibers for enhanced strength and durability, making it ideal for heavy-duty packaging. Bleached cardboard undergoes a chemical whitening process that removes lignin, resulting in a smoother, white surface with shorter fibers that offer better printability but reduced tensile strength. The material composition of kraft cardboard emphasizes resilience through mechanical fiber preservation, whereas bleached cardboard focuses on aesthetic quality by optimizing fiber brightness and surface smoothness.

Strength and Durability Differences

Kraft cardboard offers superior strength and durability due to its unbleached fibers, providing enhanced resistance to tearing and crushing compared to bleached cardboard. Bleached cardboard, while smoother and more aesthetically appealing, tends to have reduced structural integrity because the bleaching process weakens the fiber bonds. This makes kraft cardboard the preferred choice for heavy-duty packaging requiring robust protection.

Visual Appearance and Color

Kraft cardboard features a natural brown color with a rough texture, providing an earthy and eco-friendly visual appeal ideal for rustic or organic branding. Bleached cardboard undergoes a whitening process resulting in a smooth, bright white surface that enhances print contrast and delivers a clean, polished look suitable for premium packaging. Color retention on bleached cardboard allows for vibrant graphic reproduction, whereas kraft cardboard's muted tones complement minimalist designs and sustainable aesthetics.

Environmental Impact and Sustainability

Kraft cardboard is produced using fewer chemicals and retains natural fibers, resulting in lower environmental impact and higher biodegradability compared to bleached cardboard. Bleached cardboard undergoes chemical treatments that increase pollution and reduce recyclability, negatively affecting sustainability. Choosing kraft cardboard supports eco-friendly packaging solutions by minimizing energy use and waste in production.

Suitability for Packaging Applications

Kraft cardboard offers superior strength and durability due to its unbleached fibers, making it ideal for heavy-duty packaging and shipping applications. Bleached cardboard, characterized by its smooth, white surface, is better suited for retail packaging and consumer-facing products where appearance and print quality are prioritized. The choice between Kraft and bleached cardboard depends on whether packaging requirements emphasize structural integrity or visual aesthetics.

Printing and Customization Possibilities

Kraft cardboard offers a natural, textured surface ideal for eco-friendly branding but may limit color vibrancy in printing compared to bleached cardboard. Bleached cardboard provides a smooth, bright white surface that enhances ink adhesion and produces sharper, more vivid prints ideal for intricate designs and customization. Both materials support various printing techniques, but bleached cardboard is preferred for high-detail, full-color graphics while Kraft is favored for rustic or organic aesthetics.

Cost and Market Availability

Kraft cardboard is generally more cost-effective due to its unbleached production process, making it widely available in bulk for packaging and shipping needs. Bleached cardboard, involving additional chemical treatments, tends to be more expensive and is primarily used in applications requiring a clean, white appearance. Market availability of kraft cardboard remains higher in industrial sectors, while bleached cardboard is favored for consumer-facing products where aesthetics matter.

Choosing the Right Cardboard for Your Needs

Kraft cardboard offers superior strength and durability due to its unbleached, natural fibers, making it ideal for heavy-duty packaging and shipping applications. Bleached cardboard provides a smooth, white surface preferred for printing and product presentation, enhancing brand visibility and appeal. Selecting the right cardboard depends on balancing structural requirements with aesthetic needs to ensure optimal performance and customer satisfaction.

Kraft cardboard vs Bleached cardboard Infographic

materialdif.com

materialdif.com