Wax-coated cardboard offers enhanced moisture resistance and durability, making it ideal for packaging wet or perishable items, whereas uncoated cardboard is more environmentally friendly and easier to recycle. While wax coatings provide a protective barrier against water and grease, they can complicate the recycling process compared to uncoated alternatives. Selecting between wax-coated and uncoated cardboard depends on the specific packaging needs, balancing performance with sustainability considerations.

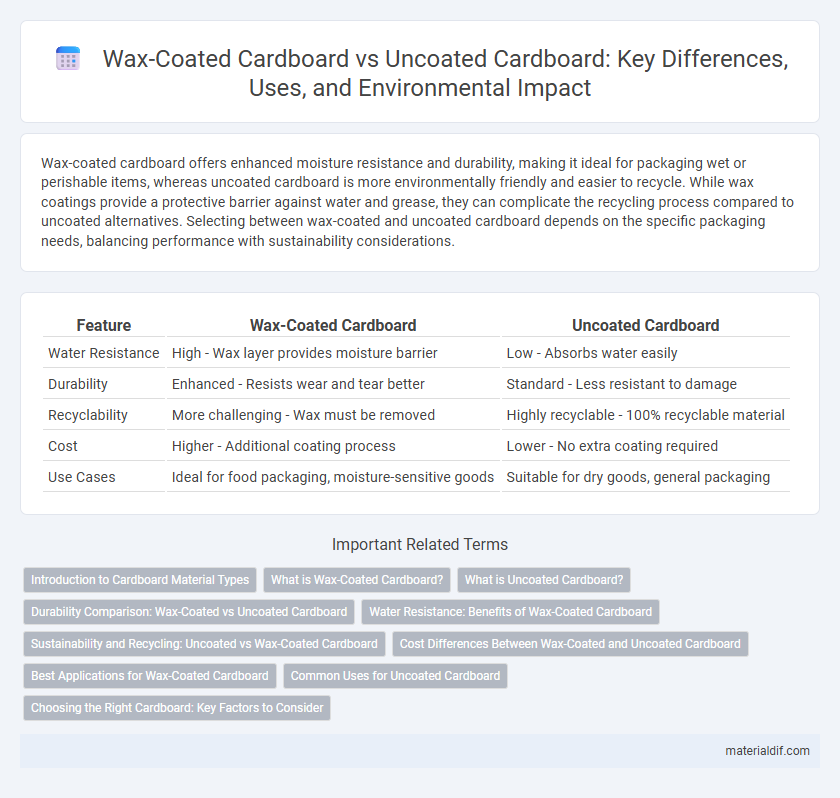

Table of Comparison

| Feature | Wax-Coated Cardboard | Uncoated Cardboard |

|---|---|---|

| Water Resistance | High - Wax layer provides moisture barrier | Low - Absorbs water easily |

| Durability | Enhanced - Resists wear and tear better | Standard - Less resistant to damage |

| Recyclability | More challenging - Wax must be removed | Highly recyclable - 100% recyclable material |

| Cost | Higher - Additional coating process | Lower - No extra coating required |

| Use Cases | Ideal for food packaging, moisture-sensitive goods | Suitable for dry goods, general packaging |

Introduction to Cardboard Material Types

Wax-coated cardboard features a thin layer of wax that enhances water resistance and durability, making it ideal for packaging perishable goods and items exposed to moisture. Uncoated cardboard lacks this protective layer, offering better recyclability and breathability, which suits dry product packaging and eco-friendly applications. Understanding these material differences is essential for selecting the appropriate cardboard type based on moisture sensitivity and environmental considerations.

What is Wax-Coated Cardboard?

Wax-coated cardboard is a type of corrugated board treated with a thin layer of wax to enhance moisture resistance and durability, making it ideal for packaging perishable goods like seafood and produce. This coating prevents water absorption, maintaining the structural integrity of the box in humid or wet environments. Unlike uncoated cardboard, wax-coated cardboard offers superior protection against liquids and extends product shelf life during transportation and storage.

What is Uncoated Cardboard?

Uncoated cardboard is a type of paperboard that lacks a wax or plastic coating, resulting in a more porous and natural surface. It is commonly used for packaging, shipping boxes, and eco-friendly products due to its recyclability and biodegradable properties. Unlike wax-coated cardboard, uncoated cardboard absorbs moisture more easily, making it less suitable for wet or greasy items.

Durability Comparison: Wax-Coated vs Uncoated Cardboard

Wax-coated cardboard offers superior moisture resistance and enhanced durability compared to uncoated cardboard, making it ideal for packaging goods prone to exposure to liquids. Uncoated cardboard, while more environmentally friendly and easier to recycle, tends to absorb water, resulting in weakened structural integrity and reduced lifespan. The choice between wax-coated and uncoated cardboard depends on the specific requirements for moisture protection and durability in the intended application.

Water Resistance: Benefits of Wax-Coated Cardboard

Wax-coated cardboard provides superior water resistance compared to uncoated cardboard, effectively repelling moisture and preventing absorption that can weaken the material. This coating enhances durability and maintains structural integrity in humid or wet environments, making it ideal for packaging perishable goods and products exposed to damp conditions. Industries such as food service and shipping benefit from wax-coated cardboard by reducing damage-related waste and ensuring product safety during transit.

Sustainability and Recycling: Uncoated vs Wax-Coated Cardboard

Uncoated cardboard is generally more sustainable due to its biodegradability and easier recyclability, as it lacks synthetic coatings that hinder processing. Wax-coated cardboard, while providing moisture resistance, often complicates recycling because the wax layer requires special treatment or disposal methods, reducing overall eco-friendliness. Choosing uncoated cardboard supports a circular economy by facilitating efficient recycling and minimizing environmental impact compared to wax-coated alternatives.

Cost Differences Between Wax-Coated and Uncoated Cardboard

Wax-coated cardboard typically incurs higher production costs due to the additional materials and manufacturing processes involved in applying the wax layer. Uncoated cardboard, being simpler to produce, generally offers a more economical option with lower material and processing expenses. These cost differences influence packaging choices, especially when moisture resistance from wax coating is not essential.

Best Applications for Wax-Coated Cardboard

Wax-coated cardboard offers superior moisture resistance, making it ideal for packaging perishable food items such as fruits, vegetables, and baked goods. Its water-repellent surface also enhances protection during transportation and storage in humid environments. This durability extends the shelf life of products and reduces the risk of contamination or spoilage.

Common Uses for Uncoated Cardboard

Uncoated cardboard is widely used in packaging applications where breathability and recyclability are essential, such as shipping boxes, product displays, and book covers. Its porous surface allows for easy printing and better adhesion of inks, making it ideal for promotional materials and eco-friendly packaging solutions. This type of cardboard is favored in industries aiming to reduce environmental impact while maintaining durability.

Choosing the Right Cardboard: Key Factors to Consider

Wax-coated cardboard offers superior moisture resistance and enhanced durability, making it ideal for packaging perishable goods or items exposed to humidity. Uncoated cardboard provides better recyclability and cost-effectiveness, suitable for dry goods and eco-friendly packaging solutions. Key factors to consider when choosing the right cardboard include the product's moisture exposure, environmental impact requirements, and budget constraints.

Wax-coated cardboard vs Uncoated cardboard Infographic

materialdif.com

materialdif.com