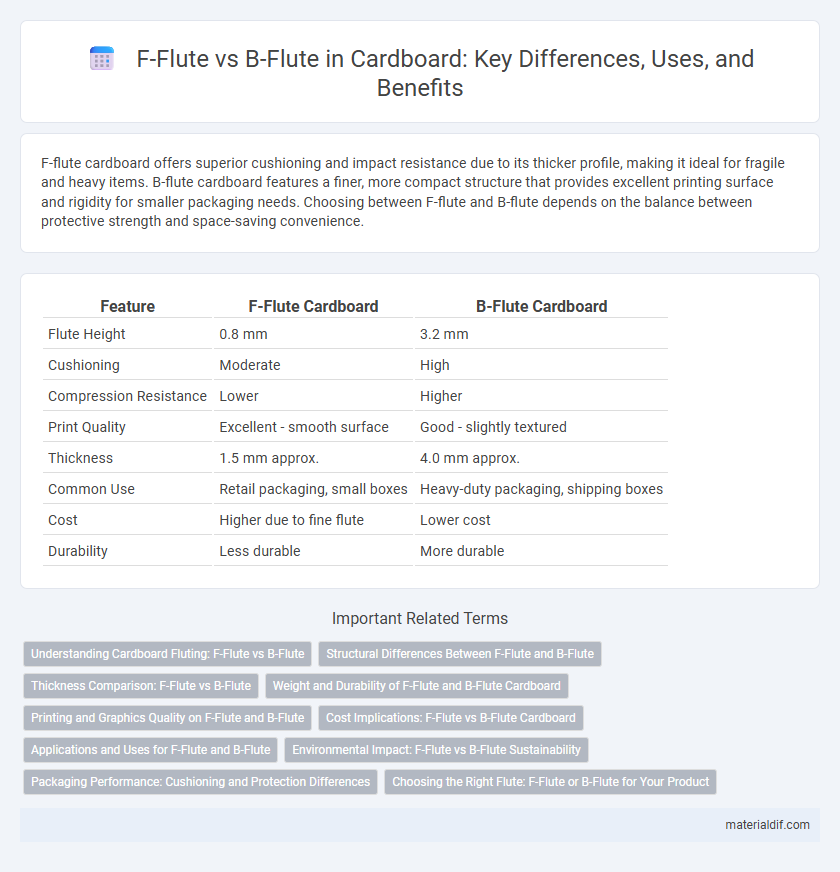

F-flute cardboard offers superior cushioning and impact resistance due to its thicker profile, making it ideal for fragile and heavy items. B-flute cardboard features a finer, more compact structure that provides excellent printing surface and rigidity for smaller packaging needs. Choosing between F-flute and B-flute depends on the balance between protective strength and space-saving convenience.

Table of Comparison

| Feature | F-Flute Cardboard | B-Flute Cardboard |

|---|---|---|

| Flute Height | 0.8 mm | 3.2 mm |

| Cushioning | Moderate | High |

| Compression Resistance | Lower | Higher |

| Print Quality | Excellent - smooth surface | Good - slightly textured |

| Thickness | 1.5 mm approx. | 4.0 mm approx. |

| Common Use | Retail packaging, small boxes | Heavy-duty packaging, shipping boxes |

| Cost | Higher due to fine flute | Lower cost |

| Durability | Less durable | More durable |

Understanding Cardboard Fluting: F-Flute vs B-Flute

F-flute cardboard features a thickness of approximately 1.5mm with around 47 flutes per foot, providing excellent printability and surface smoothness for high-quality packaging designs. B-flute cardboard is thicker, about 2.5mm, with roughly 34 flutes per foot, offering superior cushioning and puncture resistance ideal for heavier items. Choosing between F-flute and B-flute depends on the need for packaging strength versus print clarity and compactness.

Structural Differences Between F-Flute and B-Flute

F-flute cardboard features a thickness of approximately 1.5 mm with 90 flutes per foot, providing excellent crush resistance and surface for printing. B-flute cardboard, measuring around 3 mm thick with 47 flutes per foot, offers superior stacking strength and cushioning for heavier items. The structural difference lies in the flute height and frequency, affecting durability, flexibility, and application suitability in packaging.

Thickness Comparison: F-Flute vs B-Flute

F-flute cardboard measures approximately 1.5 millimeters in thickness, offering a fine flute profile ideal for retail packaging and printing applications. B-flute is thicker, around 2.5 millimeters, providing enhanced cushioning and stacking strength suitable for heavier or more fragile items. The thickness difference between F-flute and B-flute impacts durability, with B-flute delivering greater protection due to its larger flute size.

Weight and Durability of F-Flute and B-Flute Cardboard

F-flute cardboard typically weighs around 43-55 lb/MSF and offers moderate durability with fine cushioning, suitable for lightweight packaging. B-flute cardboard is heavier, approximately 51-68 lb/MSF, providing increased strength and superior resistance to crushing and punctures, making it ideal for heavier or more fragile items. The denser construction of B-flute enhances durability, while F-flute is preferred for its lightweight and smoother surface for printing.

Printing and Graphics Quality on F-Flute and B-Flute

F-flute cardboard offers superior printing and graphics quality due to its finer flute profile, allowing for crisper, more detailed images and smoother surface texture ideal for high-resolution printing. B-flute, with its thicker profile, provides good printability but may result in slightly less sharp graphics and more texture showing through, which can affect the overall visual appeal. Choosing F-flute is optimal for packaging that prioritizes vibrant and precise graphic reproduction, especially in retail and marketing applications.

Cost Implications: F-Flute vs B-Flute Cardboard

F-flute cardboard offers a finer flute structure that provides better cushioning and printability at a higher material cost compared to B-flute. B-flute cardboard, with its thicker flute, delivers enhanced rigidity and durability while being more cost-effective for bulk packaging applications. Selecting between F-flute and B-flute involves balancing budget constraints with performance requirements, influencing overall packaging expenses.

Applications and Uses for F-Flute and B-Flute

F-flute cardboard, measuring approximately 1.5mm in thickness, offers superior cushioning and surface printability, making it ideal for retail packaging, point-of-purchase displays, and protective packaging for fragile items. B-flute, slightly thinner at about 3mm, provides excellent stacking strength and crush resistance, commonly used for food packaging, printed boxes, and shipping containers requiring durability and compression resistance. Both flutes serve different market needs; F-flute excels in high-quality printing and compact packaging, while B-flute suits applications demanding structural support and impact protection.

Environmental Impact: F-Flute vs B-Flute Sustainability

F-flute cardboard offers enhanced sustainability due to its thinner profile, resulting in lower material usage and reduced weight, which decreases carbon emissions during transportation. In contrast, B-flute, while providing greater durability and cushioning, typically uses more fiber, leading to higher resource consumption and a larger environmental footprint. Choosing F-flute supports eco-friendly packaging initiatives by optimizing material efficiency and minimizing waste in recyclable corrugated boxes.

Packaging Performance: Cushioning and Protection Differences

F-flute cardboard, with its thicker profile of about 1/8 inch, offers superior cushioning and shock absorption, making it ideal for fragile or heavy items requiring enhanced protection during shipping. B-flute cardboard, thinner at approximately 1/16 inch, provides a smoother surface and better crush resistance, suitable for retail packaging and items needing more compact or aesthetically pleasing containers. The choice between F-flute and B-flute impacts packaging performance by balancing cushioning needs against structural rigidity and space efficiency.

Choosing the Right Flute: F-Flute or B-Flute for Your Product

F-flute offers a thinner profile with approximately 125 flutes per foot, delivering superior printability and excellent cushioning ideal for small, lightweight products or retail packaging. B-flute, with around 47 flutes per foot, provides greater crushing resistance and higher stacking strength, making it suitable for heavier items and shipping containers. Selecting between F-flute and B-flute depends on balancing protection requirements, print quality, and product weight to optimize packaging performance.

F-flute vs B-flute Infographic

materialdif.com

materialdif.com