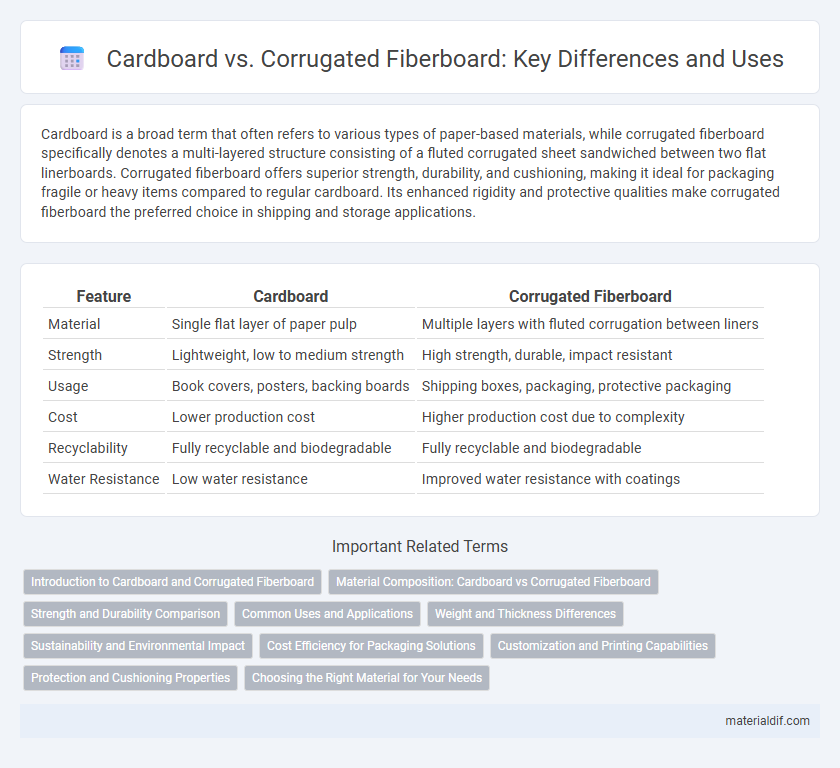

Cardboard is a broad term that often refers to various types of paper-based materials, while corrugated fiberboard specifically denotes a multi-layered structure consisting of a fluted corrugated sheet sandwiched between two flat linerboards. Corrugated fiberboard offers superior strength, durability, and cushioning, making it ideal for packaging fragile or heavy items compared to regular cardboard. Its enhanced rigidity and protective qualities make corrugated fiberboard the preferred choice in shipping and storage applications.

Table of Comparison

| Feature | Cardboard | Corrugated Fiberboard |

|---|---|---|

| Material | Single flat layer of paper pulp | Multiple layers with fluted corrugation between liners |

| Strength | Lightweight, low to medium strength | High strength, durable, impact resistant |

| Usage | Book covers, posters, backing boards | Shipping boxes, packaging, protective packaging |

| Cost | Lower production cost | Higher production cost due to complexity |

| Recyclability | Fully recyclable and biodegradable | Fully recyclable and biodegradable |

| Water Resistance | Low water resistance | Improved water resistance with coatings |

Introduction to Cardboard and Corrugated Fiberboard

Cardboard is a flat, stiff material made from pressed wood fibers, commonly used for packaging and crafting due to its lightweight and rigid properties. Corrugated fiberboard consists of a fluted corrugated sheet sandwiched between two flat linerboards, providing enhanced strength and cushioning ideal for shipping and bulky packaging. The primary distinction lies in corrugated fiberboard's structural design, which offers superior durability and protection compared to the simpler, thinner composition of standard cardboard.

Material Composition: Cardboard vs Corrugated Fiberboard

Cardboard typically consists of a single layer of paper-based material, offering lightweight and simple construction ideal for packaging light items. Corrugated fiberboard features a fluted corrugated sheet sandwiched between two flat linerboards, providing enhanced strength, cushioning, and durability for shipping and storage. The unique multi-layer composition of corrugated fiberboard delivers superior impact resistance compared to the flat, single-ply structure of standard cardboard.

Strength and Durability Comparison

Cardboard, typically made from a single layer of paper pulp, offers moderate strength suitable for lightweight packaging, while corrugated fiberboard features a fluted inner layer sandwiched between two linerboards, providing superior strength and durability. The fluted structure of corrugated fiberboard absorbs shocks and resists bending, making it ideal for heavy-duty shipping and protection of fragile items. Compared to cardboard, corrugated fiberboard demonstrates enhanced load-bearing capacity, puncture resistance, and longevity in varying environmental conditions.

Common Uses and Applications

Cardboard is typically used for lightweight packaging, arts and crafts, and product displays due to its smooth surface and ease of printing. Corrugated fiberboard, composed of a fluted corrugated sheet sandwiched between linerboards, excels in shipping containers and protective packaging because of its superior strength and durability. Industries such as e-commerce, food delivery, and heavy equipment shipping often rely on corrugated fiberboard for secure transport and storage solutions.

Weight and Thickness Differences

Cardboard is typically thinner and lighter than corrugated fiberboard, making it suitable for lightweight packaging and simple crafts. Corrugated fiberboard consists of multiple layers, including a fluted corrugated sheet between liners, which increases its thickness and weight, providing enhanced strength and durability. These structural differences result in corrugated fiberboard being the preferred material for shipping boxes and heavy-duty packaging applications due to its superior cushioning and load-bearing capacity.

Sustainability and Environmental Impact

Cardboard, typically composed of solid paperboard, has a lower environmental footprint but offers less strength compared to corrugated fiberboard, which consists of layered fluted paper that increases durability and recyclability. Corrugated fiberboard excels in sustainability due to its high recyclability rate, often exceeding 90%, and its ability to be produced from a significant percentage of recycled content, reducing reliance on virgin materials. Both materials are biodegradable, but corrugated fiberboard's structure enables more efficient reuse in packaging, contributing to reduced waste in supply chains.

Cost Efficiency for Packaging Solutions

Cardboard, often made from a single layer of fiberboard, generally offers lower cost efficiency compared to corrugated fiberboard, which features multiple layers including fluted liners providing enhanced durability. Corrugated fiberboard's superior strength reduces damage risk during shipping, minimizing product loss and overall packaging expenses despite its higher upfront cost. For businesses prioritizing long-term savings and protective packaging, corrugated fiberboard delivers better cost efficiency through improved performance and reduced replacement rates.

Customization and Printing Capabilities

Corrugated fiberboard offers superior customization and printing capabilities compared to standard cardboard, allowing for detailed graphics, vibrant colors, and variable designs tailored to brand requirements. Its multi-layered structure supports high-quality direct printing and embossing, enhancing both aesthetic appeal and functionality for packaging solutions. This makes corrugated fiberboard ideal for businesses seeking durable, visually impactful packaging with flexible customization options.

Protection and Cushioning Properties

Cardboard offers moderate protection and cushioning, suitable for lightweight items and short-term storage, but lacks the robustness needed for heavy or fragile goods. Corrugated fiberboard features a fluted layer between liners that significantly enhances shock absorption, impact resistance, and overall durability. This makes corrugated fiberboard the preferred choice for packaging requiring superior protection during shipping and handling.

Choosing the Right Material for Your Needs

Cardboard typically refers to a single-layered, less durable material suitable for lightweight packaging, while corrugated fiberboard consists of multiple layers, offering superior strength and cushioning for heavier or fragile items. Selecting the right material depends on factors like the weight of the product, protection level needed during shipping, and cost efficiency. For heavy-duty shipping and protection against impact, corrugated fiberboard is preferred, whereas for simple, lightweight packaging, cardboard serves as a cost-effective choice.

Cardboard vs Corrugated Fiberboard Infographic

materialdif.com

materialdif.com