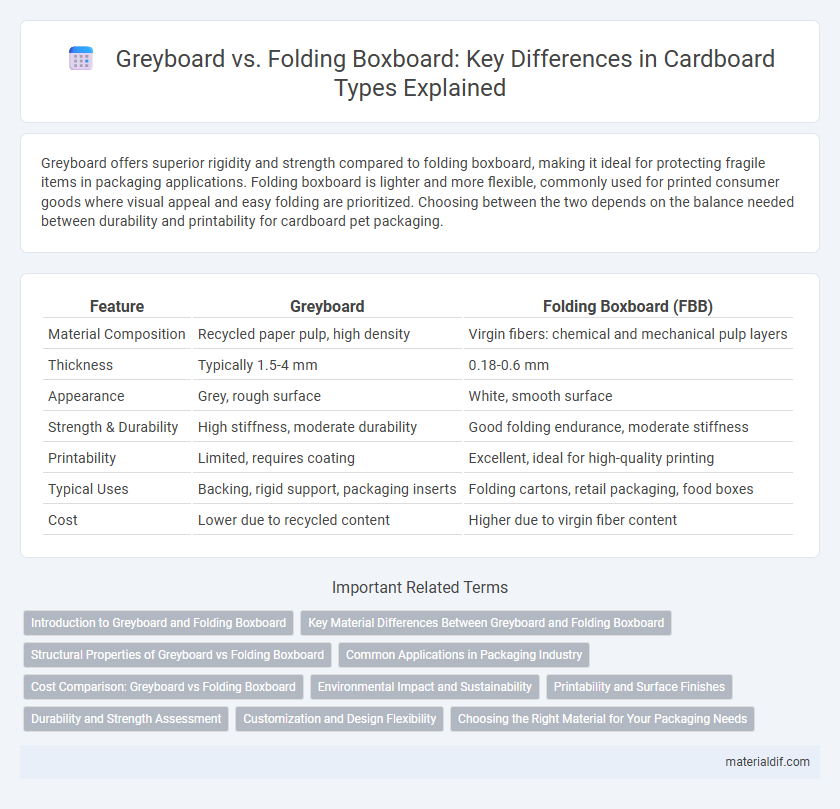

Greyboard offers superior rigidity and strength compared to folding boxboard, making it ideal for protecting fragile items in packaging applications. Folding boxboard is lighter and more flexible, commonly used for printed consumer goods where visual appeal and easy folding are prioritized. Choosing between the two depends on the balance needed between durability and printability for cardboard pet packaging.

Table of Comparison

| Feature | Greyboard | Folding Boxboard (FBB) |

|---|---|---|

| Material Composition | Recycled paper pulp, high density | Virgin fibers: chemical and mechanical pulp layers |

| Thickness | Typically 1.5-4 mm | 0.18-0.6 mm |

| Appearance | Grey, rough surface | White, smooth surface |

| Strength & Durability | High stiffness, moderate durability | Good folding endurance, moderate stiffness |

| Printability | Limited, requires coating | Excellent, ideal for high-quality printing |

| Typical Uses | Backing, rigid support, packaging inserts | Folding cartons, retail packaging, food boxes |

| Cost | Lower due to recycled content | Higher due to virgin fiber content |

Introduction to Greyboard and Folding Boxboard

Greyboard is a type of thick, rigid paperboard made primarily from recycled fibers, commonly used for backing, bookbinding, and packaging applications requiring durability and strength. Folding boxboard, in contrast, is a lightweight, multilayered paperboard designed for folding and printing, often used in consumer goods packaging such as cereal boxes and cosmetics. Both materials serve distinct purposes in packaging, with greyboard offering robust structural support and folding boxboard providing flexibility and high-quality surface printability.

Key Material Differences Between Greyboard and Folding Boxboard

Greyboard, primarily made from recycled paper fibers, features a dense, rigid structure ideal for packaging heavy or bulky items, while folding boxboard consists of multiple layers of bleached chemical pulp and mechanical pulp, offering a lighter, more flexible material suited for consumer packaging. Greyboard generally exhibits higher stiffness and thickness, enhancing durability and protection, whereas folding boxboard provides a smoother surface and better printability for high-quality graphics. The key material difference lies in their composition and functionality: greyboard's robustness contrasts with folding boxboard's versatility and aesthetic appeal.

Structural Properties of Greyboard vs Folding Boxboard

Greyboard exhibits superior rigidity and higher grammage, making it ideal for durable packaging and bookbinding applications. Folding boxboard, characterized by its lighter weight and better folding endurance, offers enhanced flexibility and printability suitable for consumer product packaging. The structural difference lies in greyboard's thick, layered composition versus the multi-ply, more refined surface of folding boxboard, impacting their respective strength and functional uses.

Common Applications in Packaging Industry

Greyboard is commonly used in rigid packaging applications such as book covers, picture frames, and luxury product boxes due to its high density and durability. Folding boxboard finds extensive use in packaging for consumer goods like food, cosmetics, and pharmaceuticals because of its lightweight properties and excellent printability. Both materials serve critical roles in the packaging industry, balancing structural strength and aesthetic appeal based on product requirements.

Cost Comparison: Greyboard vs Folding Boxboard

Greyboard generally costs less than folding boxboard due to its recycled content and lower manufacturing complexity. Folding boxboard offers higher strength and printability, which increases its price, making it suitable for premium packaging despite higher costs. Cost differences can range from 10% to 30%, depending on quality specifications and supply chain factors.

Environmental Impact and Sustainability

Greyboard typically has a higher recycled fiber content, making it more sustainable by reducing the demand for virgin materials and lowering landfill waste. Folding boxboard, while offering superior printability and strength, often involves more virgin pulp, which may result in a larger environmental footprint. Choosing greyboard supports circular economy principles through enhanced recyclability and reduced resource consumption.

Printability and Surface Finishes

Greyboard offers a rougher surface that may require additional coating for high-quality print finishes, making it less ideal for detailed graphic printing compared to Folding boxboard. Folding boxboard features a smooth, multi-layered structure that provides excellent printability and allows for a wide range of surface finishes, including glossy, matte, or textured effects. Its superior surface uniformity enhances ink adhesion and sharpness, making it the preferred choice for premium packaging designs.

Durability and Strength Assessment

Greyboard exhibits higher density and stiffness, making it more durable for heavy-duty packaging applications requiring strong structural integrity. Folding boxboard offers superior foldability and smooth printing surfaces but has lower resistance to mechanical stress compared to greyboard. The choice depends on balancing required strength against flexibility and aesthetic demands in packaging design.

Customization and Design Flexibility

Greyboard offers limited customization and design flexibility due to its rigid and dense structure, making it ideal for sturdy, protective packaging but less adaptable for intricate shapes or detailed graphics. Folding boxboard provides superior design versatility with its smooth surface and ability to be easily creased, printed, and folded into complex shapes, allowing for high-quality visual customization. Brands seeking detailed artwork and unique packaging designs typically prefer folding boxboard for its enhanced customization options and flexibility.

Choosing the Right Material for Your Packaging Needs

Greyboard offers superior rigidity and durability, making it ideal for heavy-duty packaging that requires enhanced protection. Folding boxboard features a smooth surface and excellent printability, suited for consumer-facing packaging emphasizing aesthetics and branding. Selecting between greyboard and folding boxboard depends on the balance of structural strength and visual presentation required for your product's packaging.

Greyboard vs Folding boxboard Infographic

materialdif.com

materialdif.com