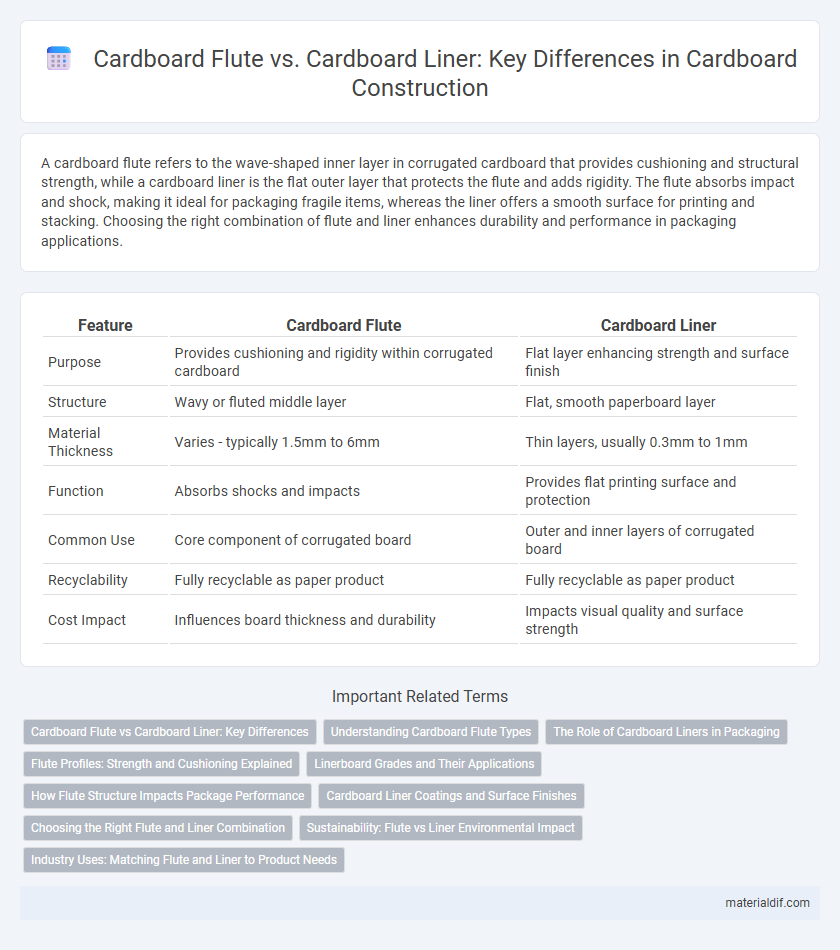

A cardboard flute refers to the wave-shaped inner layer in corrugated cardboard that provides cushioning and structural strength, while a cardboard liner is the flat outer layer that protects the flute and adds rigidity. The flute absorbs impact and shock, making it ideal for packaging fragile items, whereas the liner offers a smooth surface for printing and stacking. Choosing the right combination of flute and liner enhances durability and performance in packaging applications.

Table of Comparison

| Feature | Cardboard Flute | Cardboard Liner |

|---|---|---|

| Purpose | Provides cushioning and rigidity within corrugated cardboard | Flat layer enhancing strength and surface finish |

| Structure | Wavy or fluted middle layer | Flat, smooth paperboard layer |

| Material Thickness | Varies - typically 1.5mm to 6mm | Thin layers, usually 0.3mm to 1mm |

| Function | Absorbs shocks and impacts | Provides flat printing surface and protection |

| Common Use | Core component of corrugated board | Outer and inner layers of corrugated board |

| Recyclability | Fully recyclable as paper product | Fully recyclable as paper product |

| Cost Impact | Influences board thickness and durability | Impacts visual quality and surface strength |

Cardboard Flute vs Cardboard Liner: Key Differences

Cardboard flute refers to the corrugated medium that provides cushioning and structural strength in corrugated cardboard, consisting of wave-shaped paper sandwiched between liners. Cardboard liner, on the other hand, is the flat paperboard layer that forms the outer surfaces of corrugated cardboard, offering printability and surface protection. The key differences lie in their functions: flutes add rigidity and shock absorption, while liners ensure durability and provide a smooth, printable surface.

Understanding Cardboard Flute Types

Cardboard flute types vary in thickness and durability, affecting packaging strength and cushioning properties. A cardboard flute consists of the corrugated medium between flat liners, while a cardboard liner refers to the flat outer sheets that provide surface strength and printability. Understanding the flute size, such as A-flute for cushioning or B-flute for rigidity, is essential when choosing between cardboard flute and liner for specific packaging needs.

The Role of Cardboard Liners in Packaging

Cardboard liners provide structural support and cushioning within packaging, enhancing product protection during transit. These liners prevent direct contact between the item and the outer cardboard flute, reducing wear and tear caused by friction or impact. By maintaining the integrity of the package, cardboard liners contribute to overall durability and customer satisfaction in shipping and storage.

Flute Profiles: Strength and Cushioning Explained

Cardboard flute profiles vary in thickness and structure, directly influencing strength and cushioning properties essential for packaging durability. A cardboard flute, such as A-flute or B-flute, provides greater rigidity and impact resistance, making it ideal for heavier or fragile items, whereas a cardboard liner offers a smooth, flat surface that enhances printability and stacking strength but less cushioning. Selecting the appropriate flute profile balances the need for protecting goods with optimizing material efficiency in shipping and storage.

Linerboard Grades and Their Applications

Linerboard grades in cardboard production vary primarily in basis weight and fiber composition, influencing their stiffness and durability for specific packaging needs. A cardboard flute combined with appropriate linerboard grades enhances cushioning and structural integrity, making it ideal for fragile item protection during shipping. High-quality virgin fiber linerboards excel in printability and strength, while recycled fiber grades offer cost-effective solutions for less demanding packaging applications.

How Flute Structure Impacts Package Performance

The flute structure in cardboard significantly influences package performance by enhancing cushioning and rigidity, where larger flutes provide superior shock absorption and stacking strength. Cardboard flutes vary in thickness and shape, directly affecting ventilation, durability, and the ability to protect fragile contents. Compared to cardboard liners, which primarily offer inner surface support, flutes improve overall package resilience against impacts and compression during shipping and handling.

Cardboard Liner Coatings and Surface Finishes

Cardboard liner coatings and surface finishes significantly enhance durability, moisture resistance, and print quality, making them essential for packaging applications. Glossy and matte finishes improve visual appeal and tactile experience, while specialized coatings like clay or polyethylene provide barrier properties against grease and water. These coatings transform standard cardboard liners into versatile materials suitable for food packaging, retail displays, and shipping containers.

Choosing the Right Flute and Liner Combination

Selecting the right cardboard flute and liner combination directly influences the durability and cushioning of packaging materials. Flutes, such as A, B, C, E, or F, determine thickness and compression strength, while liners affect surface smoothness and printing quality. Matching the flute type with an appropriate liner balances protection, weight, and cost, optimizing cardboard performance for specific shipping and storage needs.

Sustainability: Flute vs Liner Environmental Impact

Cardboard flute provides structural strength using corrugated layers made from recycled paper, significantly reducing material use and waste compared to solid liners. Cardboard liners, while offering smooth surfaces for packaging, often require additional coatings or treatments that hinder recyclability and increase environmental footprint. Choosing flute over liner enhances sustainability by optimizing resource efficiency and promoting easier recycling in packaging applications.

Industry Uses: Matching Flute and Liner to Product Needs

Cardboard flute types such as A-flute, B-flute, and C-flute are selected based on cushioning, stacking strength, and printability requirements, making them ideal for products needing varying levels of protection during shipping. Cardboard liners complement these flutes by providing smooth surfaces for printing and additional rigidity, crucial in packaging fragile or high-value goods in the food, electronics, and cosmetic industries. Matching the appropriate flute profile with a compatible liner ensures optimal product protection, material efficiency, and cost-effectiveness in diverse industrial applications.

Cardboard flute vs Cardboard liner Infographic

materialdif.com

materialdif.com