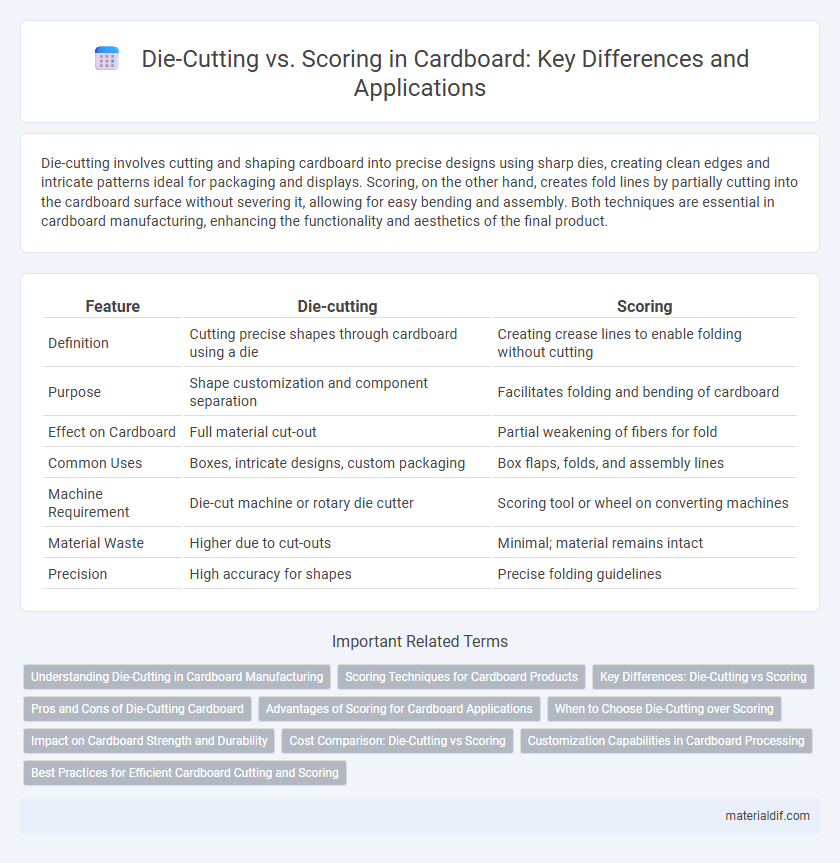

Die-cutting involves cutting and shaping cardboard into precise designs using sharp dies, creating clean edges and intricate patterns ideal for packaging and displays. Scoring, on the other hand, creates fold lines by partially cutting into the cardboard surface without severing it, allowing for easy bending and assembly. Both techniques are essential in cardboard manufacturing, enhancing the functionality and aesthetics of the final product.

Table of Comparison

| Feature | Die-cutting | Scoring |

|---|---|---|

| Definition | Cutting precise shapes through cardboard using a die | Creating crease lines to enable folding without cutting |

| Purpose | Shape customization and component separation | Facilitates folding and bending of cardboard |

| Effect on Cardboard | Full material cut-out | Partial weakening of fibers for fold |

| Common Uses | Boxes, intricate designs, custom packaging | Box flaps, folds, and assembly lines |

| Machine Requirement | Die-cut machine or rotary die cutter | Scoring tool or wheel on converting machines |

| Material Waste | Higher due to cut-outs | Minimal; material remains intact |

| Precision | High accuracy for shapes | Precise folding guidelines |

Understanding Die-Cutting in Cardboard Manufacturing

Die-cutting in cardboard manufacturing involves using specialized machines and sharp steel blades to precisely cut shapes, patterns, or designs from cardboard sheets, ensuring high accuracy and repeatability. This process is crucial for producing intricate packaging components, such as folding cartons and inserts, with clean edges and minimal material waste. Unlike scoring, which creates fold lines by partially cutting the cardboard surface, die-cutting fully separates parts, enabling complex assembly and enhanced product presentation.

Scoring Techniques for Cardboard Products

Scoring techniques for cardboard products involve creating precise creases that allow for smooth and accurate folding without damaging the material's structural integrity. This process uses specialized tools such as metal wheels or blades to compress the fibers along a defined line, facilitating clean bends and enhancing product durability. Effective scoring improves assembly efficiency and ensures consistent quality in packaging, displays, and other cardboard applications.

Key Differences: Die-Cutting vs Scoring

Die-cutting involves cutting precise shapes or patterns out of cardboard using custom-made dies, enabling complex designs and perforations, while scoring creates creases or fold lines without cutting through the material, allowing easy bending and folding. Die-cutting is essential for producing intricate packaging shapes, whereas scoring ensures clean, accurate folds in the cardboard structure. The key difference lies in die-cutting removing material to form shapes, whereas scoring only manipulates the surface for flexibility.

Pros and Cons of Die-Cutting Cardboard

Die-cutting cardboard enables precise and intricate shapes, enhancing design flexibility and production efficiency for packaging and displays. This method often results in higher initial tooling costs but reduces manual labor and waste, leading to lower per-unit costs in large runs. However, die-cutting may cause material stress or weak points if not properly calibrated, potentially compromising durability in some applications.

Advantages of Scoring for Cardboard Applications

Scoring cardboard enables precise folding by creating a controlled crease without breaking the material, which maintains structural integrity and enhances durability in packaging designs. This technique reduces the risk of cracking or tearing during assembly, resulting in cleaner and more professional edges. Scoring also increases manufacturing efficiency by facilitating faster and more consistent folds, essential for large-scale cardboard production.

When to Choose Die-Cutting over Scoring

Die-cutting is ideal when creating complex shapes, precise cuts, or custom designs in cardboard that scoring cannot achieve, such as perforated edges, intricate patterns, or packaging windows. It offers clean, sharp edges and allows for full separation of pieces, essential for producing packaging, promotional displays, or unique box structures with high accuracy. When the project requires detailed cutting beyond simple folds, die-cutting ensures superior quality and design versatility compared to scoring alone.

Impact on Cardboard Strength and Durability

Die-cutting creates precise shapes and cuts in cardboard by removing material, which can reduce the overall structural integrity and weaken the cardboard's strength and durability. Scoring, on the other hand, involves creating creases without fully cutting through the material, allowing for controlled folding while maintaining the cardboard's strength and resistance to tearing. Choosing scoring over die-cutting helps preserve the cardboard's durability, especially in packaging applications that require repeated handling or weight support.

Cost Comparison: Die-Cutting vs Scoring

Die-cutting generally involves higher upfront costs due to the need for custom dies and setup, making it more cost-effective for large production runs or intricate designs. Scoring requires less initial investment, as it primarily involves creating fold lines without complex tooling, reducing expenses for smaller batches or simpler projects. Comparing cost-efficiency, die-cutting delivers savings over time with volume, whereas scoring remains the economical choice for short runs and basic cardboard modifications.

Customization Capabilities in Cardboard Processing

Die-cutting enables precise, intricate shapes and designs to be cut out of cardboard, allowing for high customization in packaging and product presentation. Scoring facilitates controlled folding by creating creases without cutting through the material, which is essential for custom box shapes and structural integrity. Combining die-cutting with scoring enhances the customization capabilities of cardboard processing, enabling tailored packaging solutions with unique forms and functional folds.

Best Practices for Efficient Cardboard Cutting and Scoring

Die-cutting and scoring are essential techniques in cardboard fabrication, with die-cutting providing precise cuts for intricate shapes and scoring creating controlled folds without damaging the material's structure. Best practices include selecting the appropriate blade type and pressure settings for die-cutting to avoid tearing, and ensuring accurate scoring depth to maintain structural integrity while allowing crisp folds. Utilizing automated machinery with adjustable parameters enhances efficiency and consistency in both cutting and scoring processes, optimizing production quality and reducing material waste.

Die-cutting vs Scoring Infographic

materialdif.com

materialdif.com