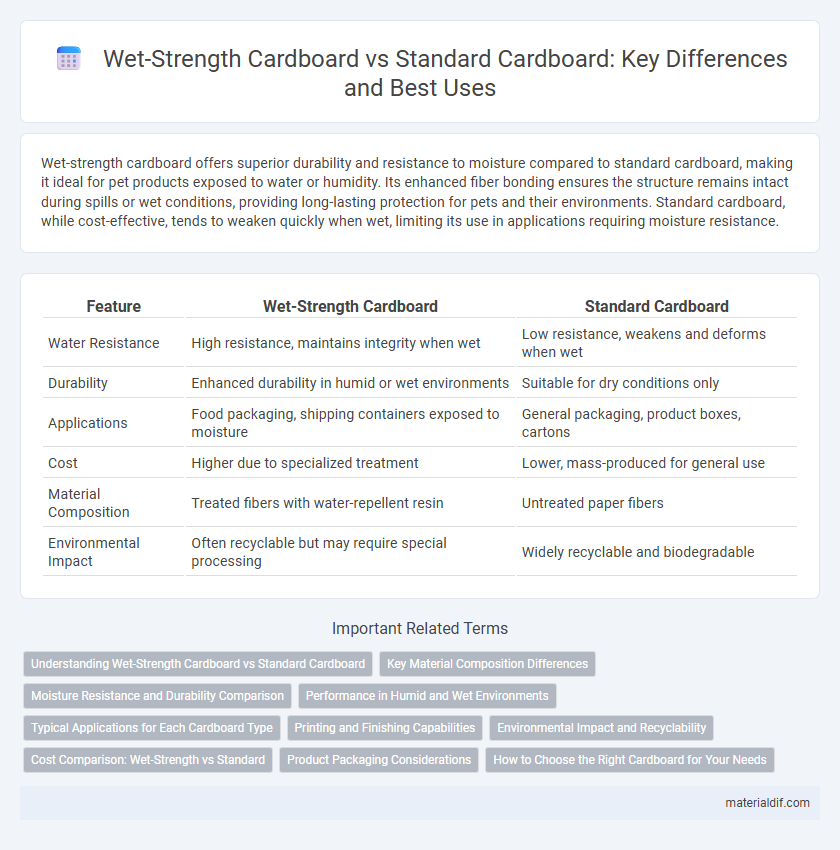

Wet-strength cardboard offers superior durability and resistance to moisture compared to standard cardboard, making it ideal for pet products exposed to water or humidity. Its enhanced fiber bonding ensures the structure remains intact during spills or wet conditions, providing long-lasting protection for pets and their environments. Standard cardboard, while cost-effective, tends to weaken quickly when wet, limiting its use in applications requiring moisture resistance.

Table of Comparison

| Feature | Wet-Strength Cardboard | Standard Cardboard |

|---|---|---|

| Water Resistance | High resistance, maintains integrity when wet | Low resistance, weakens and deforms when wet |

| Durability | Enhanced durability in humid or wet environments | Suitable for dry conditions only |

| Applications | Food packaging, shipping containers exposed to moisture | General packaging, product boxes, cartons |

| Cost | Higher due to specialized treatment | Lower, mass-produced for general use |

| Material Composition | Treated fibers with water-repellent resin | Untreated paper fibers |

| Environmental Impact | Often recyclable but may require special processing | Widely recyclable and biodegradable |

Understanding Wet-Strength Cardboard vs Standard Cardboard

Wet-strength cardboard contains added resins that enhance its durability and resistance to water damage, making it ideal for packaging products exposed to moisture. Standard cardboard lacks these reinforcing agents, causing it to weaken and lose structural integrity when wet. This distinction is crucial for selecting packaging materials in industries such as food delivery and pharmaceuticals, where moisture exposure is common.

Key Material Composition Differences

Wet-strength cardboard contains synthetic resins like urea-formaldehyde or melamine-formaldehyde that enhance water resistance and structural integrity when exposed to moisture. Standard cardboard primarily consists of cellulose fibers derived from wood pulp, which offer limited durability against water and tend to weaken or disintegrate when wet. These key material composition differences make wet-strength cardboard ideal for applications requiring moisture resistance, such as packaging for frozen or refrigerated goods.

Moisture Resistance and Durability Comparison

Wet-strength cardboard offers significantly enhanced moisture resistance compared to standard cardboard, making it ideal for packaging items exposed to damp environments or light water contact. The durability of wet-strength cardboard is superior due to chemical treatments that reinforce fiber bonds, preventing disintegration and maintaining structural integrity under wet conditions. Standard cardboard lacks these treatments, resulting in lower resistance to moisture and reduced durability when exposed to humidity or water.

Performance in Humid and Wet Environments

Wet-strength cardboard incorporates specialized resins that significantly enhance its durability and resistance to moisture compared to standard cardboard, preventing deformation and maintaining structural integrity in humid and wet environments. Standard cardboard, lacking these reinforcing agents, tends to weaken, lose rigidity, and deteriorate rapidly when exposed to water or high humidity. This makes wet-strength cardboard ideal for packaging products requiring reliable protection against moisture, such as food items, pharmaceuticals, and electronics.

Typical Applications for Each Cardboard Type

Wet-strength cardboard is commonly used in packaging for products exposed to moisture, such as food containers, beverage carriers, and pharmaceutical packaging, due to its enhanced resistance to water and humidity. Standard cardboard serves well in shipping boxes, retail packaging, and product displays where moisture exposure is minimal, offering cost-effective protection and durability for everyday goods. Both types cater to specific market needs by balancing strength, durability, and environmental factors in various industries.

Printing and Finishing Capabilities

Wet-strength cardboard maintains structural integrity when exposed to moisture, enabling superior performance in printing processes that require wet inks or coatings without warping or bleeding. Standard cardboard, while suitable for dry printing applications, often suffers from ink absorption issues and surface deformation during finishing techniques such as laminating or UV coating. Enhanced printing sharpness and durability are achievable with wet-strength cardboard due to its resistance to moisture-induced surface irregularities and improved adhesion properties.

Environmental Impact and Recyclability

Wet-strength cardboard incorporates chemical additives to enhance durability in moist conditions, which complicates its recyclability compared to standard cardboard that is more easily processed in recycling facilities. The environmental impact of wet-strength cardboard is higher due to these resistant chemicals, resulting in potential pollution and increased energy use during recycling. Standard cardboard offers a more eco-friendly option with lower production emissions and simpler recycling processes, reducing landfill waste and promoting a circular economy.

Cost Comparison: Wet-Strength vs Standard

Wet-strength cardboard typically costs 15-30% more than standard cardboard due to added resin treatments that enhance moisture resistance. Despite higher upfront costs, wet-strength cardboard reduces product damage and replacement expenses in humid environments, offering better long-term value. Standard cardboard remains a cost-effective option for dry conditions with minimal exposure to moisture.

Product Packaging Considerations

Wet-strength cardboard is engineered with special resins to resist moisture, making it ideal for packaging products exposed to humid or damp conditions, such as fresh produce or frozen goods. Standard cardboard absorbs water quickly, losing structural integrity and increasing the risk of damage during transit and storage. Selecting wet-strength cardboard enhances durability for shipments requiring moisture resistance, ensuring product protection and maintaining brand reputation.

How to Choose the Right Cardboard for Your Needs

Wet-strength cardboard offers superior durability and moisture resistance, making it ideal for packaging products exposed to humidity or liquid, such as food and beverages. Standard cardboard is suitable for general use, providing adequate strength for dry, lightweight items but lacking moisture protection. Evaluate your product's sensitivity to moisture and handling conditions to select between wet-strength and standard cardboard for optimal performance and cost-efficiency.

Wet-strength cardboard vs Standard cardboard Infographic

materialdif.com

materialdif.com