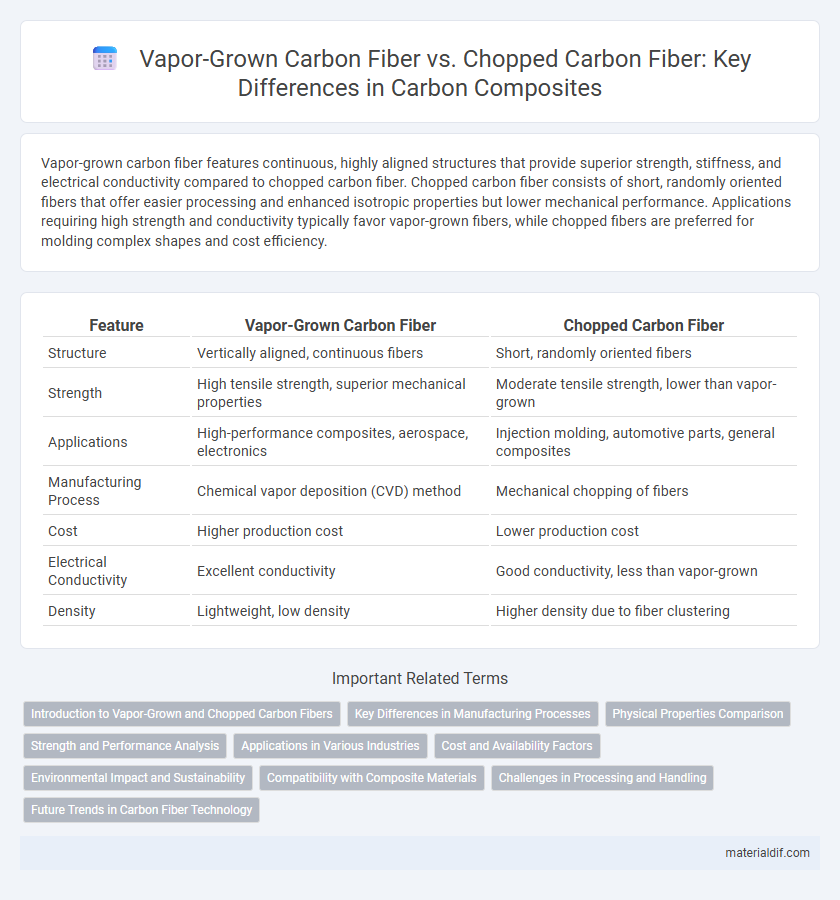

Vapor-grown carbon fiber features continuous, highly aligned structures that provide superior strength, stiffness, and electrical conductivity compared to chopped carbon fiber. Chopped carbon fiber consists of short, randomly oriented fibers that offer easier processing and enhanced isotropic properties but lower mechanical performance. Applications requiring high strength and conductivity typically favor vapor-grown fibers, while chopped fibers are preferred for molding complex shapes and cost efficiency.

Table of Comparison

| Feature | Vapor-Grown Carbon Fiber | Chopped Carbon Fiber |

|---|---|---|

| Structure | Vertically aligned, continuous fibers | Short, randomly oriented fibers |

| Strength | High tensile strength, superior mechanical properties | Moderate tensile strength, lower than vapor-grown |

| Applications | High-performance composites, aerospace, electronics | Injection molding, automotive parts, general composites |

| Manufacturing Process | Chemical vapor deposition (CVD) method | Mechanical chopping of fibers |

| Cost | Higher production cost | Lower production cost |

| Electrical Conductivity | Excellent conductivity | Good conductivity, less than vapor-grown |

| Density | Lightweight, low density | Higher density due to fiber clustering |

Introduction to Vapor-Grown and Chopped Carbon Fibers

Vapor-grown carbon fibers (VGCF) are produced through chemical vapor deposition, resulting in ultra-thin, high-strength fibers with exceptional electrical conductivity and thermal stability. Chopped carbon fibers consist of short, randomly oriented fiber segments typically derived from continuous fiber tows, offering ease of mixing into composite matrices and cost-effectiveness for mass production. VGCFs provide superior performance in advanced composites and electronic applications, while chopped fibers are widely used to enhance mechanical properties in injection molding and structural components.

Key Differences in Manufacturing Processes

Vapor-grown carbon fiber is produced by chemical vapor deposition where carbon atoms form fibers directly on a substrate, resulting in continuous, ultra-thin filaments with superior strength and conductivity. Chopped carbon fiber, by contrast, is created by mechanically cutting longer carbon fibers into short segments, which compromises fiber length and uniformity but facilitates easier integration into composite materials. The continuous nature of vapor-grown fibers yields higher performance composites, while chopped fibers offer cost-effective versatility for mass production.

Physical Properties Comparison

Vapor-grown carbon fiber exhibits higher tensile strength and modulus due to its continuous fiber structure, resulting in superior stiffness and durability compared to chopped carbon fiber. Chopped carbon fiber, characterized by shorter fiber lengths, provides improved moldability and impact resistance but generally features lower mechanical performance. Its ease of integration into various composites makes it suitable for applications requiring complex shapes rather than maximum structural integrity.

Strength and Performance Analysis

Vapor-grown carbon fiber exhibits superior tensile strength and stiffness compared to chopped carbon fiber due to its continuous fiber structure, enhancing load transfer and mechanical performance in composites. The aligned morphology of vapor-grown fibers results in higher modulus and fracture toughness, making them ideal for high-performance applications requiring durability and resilience. In contrast, chopped carbon fibers, while easier to process, tend to have reduced strength and performance due to fiber length discontinuity and less efficient stress distribution.

Applications in Various Industries

Vapor-grown carbon fiber offers superior electrical conductivity and high surface area, making it ideal for energy storage devices like batteries and supercapacitors, as well as advanced composites in aerospace and automotive industries. Chopped carbon fiber, with its ease of dispersion and cost-effectiveness, is widely used in injection molding, sporting goods, and construction materials for enhanced mechanical strength and lightweight properties. Both fibers contribute significantly to innovations in electronics, transportation, and manufacturing sectors due to their distinct characteristics tailored to specific industrial applications.

Cost and Availability Factors

Vapor-grown carbon fiber offers superior strength and conductivity but comes with significantly higher production costs and limited availability compared to chopped carbon fiber. Chopped carbon fiber is widely accessible and more cost-effective, making it suitable for mass production and budget-conscious applications. The choice between the two depends largely on balancing performance requirements against budget constraints and supply chain considerations.

Environmental Impact and Sustainability

Vapor-grown carbon fiber (VGCF) demonstrates a lower environmental impact due to its highly efficient production process that consumes less energy and produces fewer emissions compared to chopped carbon fiber manufacturing. VGCF's enhanced mechanical properties enable lighter, more durable composites, leading to extended product lifecycles and reduced material consumption, promoting sustainability. In contrast, chopped carbon fiber often involves more energy-intensive processes and greater waste generation, resulting in a larger carbon footprint and challenges in recycling and reuse.

Compatibility with Composite Materials

Vapor-grown carbon fiber exhibits superior compatibility with composite materials due to its high surface area and excellent interfacial bonding properties, enhancing the mechanical strength and durability of composites. Chopped carbon fiber, while easier to disperse and cost-effective, often results in lower reinforcement efficiency because of shorter fiber length and less optimal bonding with resin matrices. Selecting vapor-grown carbon fiber improves composite performance in aerospace, automotive, and sporting goods applications where high strength-to-weight ratios are critical.

Challenges in Processing and Handling

Vapor-grown carbon fiber presents challenges in processing due to its nanoscale dimensions, leading to difficulties in uniform dispersion and handling compared to chopped carbon fiber, which is easier to manipulate but often results in reduced mechanical properties. The high aspect ratio of vapor-grown fibers increases the risk of agglomeration, complicating composite fabrication and requiring advanced mixing techniques to achieve homogeneity. In contrast, chopped carbon fiber's shorter length improves processability but compromises the fiber-matrix interfacial bonding essential for optimal structural performance.

Future Trends in Carbon Fiber Technology

Vapor-grown carbon fiber offers superior tensile strength and electrical conductivity compared to chopped carbon fiber, making it a promising material for next-generation aerospace and energy storage applications. Future trends in carbon fiber technology emphasize enhancing fiber-matrix interfaces to improve composite durability while reducing production costs through advanced manufacturing techniques such as automated fiber placement. Research also focuses on developing sustainable vapor-grown carbon fibers from bio-based precursors, aiming to decrease the environmental impact associated with traditional carbon fiber production.

Vapor-grown carbon fiber vs Chopped carbon fiber Infographic

materialdif.com

materialdif.com