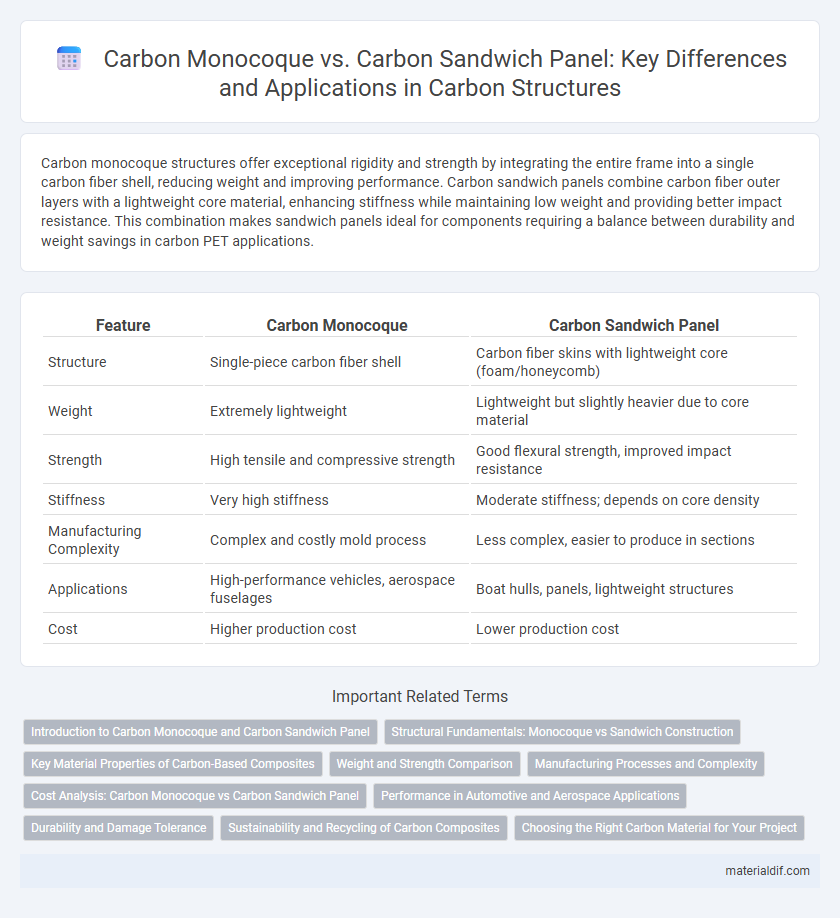

Carbon monocoque structures offer exceptional rigidity and strength by integrating the entire frame into a single carbon fiber shell, reducing weight and improving performance. Carbon sandwich panels combine carbon fiber outer layers with a lightweight core material, enhancing stiffness while maintaining low weight and providing better impact resistance. This combination makes sandwich panels ideal for components requiring a balance between durability and weight savings in carbon PET applications.

Table of Comparison

| Feature | Carbon Monocoque | Carbon Sandwich Panel |

|---|---|---|

| Structure | Single-piece carbon fiber shell | Carbon fiber skins with lightweight core (foam/honeycomb) |

| Weight | Extremely lightweight | Lightweight but slightly heavier due to core material |

| Strength | High tensile and compressive strength | Good flexural strength, improved impact resistance |

| Stiffness | Very high stiffness | Moderate stiffness; depends on core density |

| Manufacturing Complexity | Complex and costly mold process | Less complex, easier to produce in sections |

| Applications | High-performance vehicles, aerospace fuselages | Boat hulls, panels, lightweight structures |

| Cost | Higher production cost | Lower production cost |

Introduction to Carbon Monocoque and Carbon Sandwich Panel

Carbon monocoque structures utilize a single shell made entirely of carbon fiber composites, offering exceptional strength-to-weight ratios ideal for aerospace and high-performance automotive applications. Carbon sandwich panels consist of carbon fiber face sheets bonded to a lightweight core material such as foam or honeycomb, enhancing rigidity and impact resistance while minimizing weight. These materials optimize structural efficiency by balancing stiffness, durability, and weight savings for advanced engineering designs.

Structural Fundamentals: Monocoque vs Sandwich Construction

Carbon monocoque structures rely on a single, continuous carbon fiber shell that provides high stiffness and strength by distributing loads evenly across its surface. In contrast, carbon sandwich panels consist of two carbon fiber face sheets bonded to a lightweight core, optimizing stiffness-to-weight ratio by separating tension and compression forces. This fundamental difference in load distribution and core utilization defines the superior impact resistance and energy absorption characteristics in sandwich construction compared to monocoque designs.

Key Material Properties of Carbon-Based Composites

Carbon monocoque structures offer exceptional stiffness-to-weight ratios due to their unibody design, enhancing structural integrity and load distribution. Carbon sandwich panels incorporate a lightweight core material between carbon fiber skins, delivering superior impact resistance and thermal insulation properties. Both materials demonstrate high tensile strength, excellent fatigue resistance, and corrosion immunity, making them ideal for aerospace, automotive, and sporting applications.

Weight and Strength Comparison

Carbon monocoque structures offer superior strength-to-weight ratios by integrating the load-bearing shell directly into the chassis, reducing overall mass while maintaining rigidity. Carbon sandwich panels consist of carbon fiber outer skins bonded to a lightweight core, achieving excellent stiffness with minimal weight but typically less impact resistance compared to monocoque designs. Weight savings in carbon monocoque can reach up to 30% over traditional materials, while sandwich panels optimize strength in flat or curved surfaces without the complex shaping required for monocoque construction.

Manufacturing Processes and Complexity

Carbon monocoque structures are manufactured using advanced techniques like autoclave curing and resin transfer molding, requiring precise layering of carbon fiber to create a seamless, high-strength shell with minimal joints. Carbon sandwich panels involve bonding carbon fiber face sheets to a lightweight core material such as foam or honeycomb, which simplifies manufacturing by allowing separate production of core and skins but introduces complexity in adhesive application and quality control. The monocoque process demands higher skill and longer production times due to its integral design, while sandwich panels offer modularity and easier repair but require stringent inspection to prevent delamination.

Cost Analysis: Carbon Monocoque vs Carbon Sandwich Panel

Carbon monocoque structures typically incur higher manufacturing costs due to their single-piece construction and complex mold requirements, whereas carbon sandwich panels offer cost efficiencies by combining lightweight cores with carbon fiber skins, reducing material usage. The production process of carbon sandwich panels involves less labor-intensive fabrication and shorter cycle times, making them more economical for large-scale applications. Cost analysis shows that while monocoque designs provide superior strength-to-weight ratios, sandwich panels deliver a balanced compromise between performance and expense, favoring budget-conscious projects.

Performance in Automotive and Aerospace Applications

Carbon monocoque structures offer superior rigidity and weight savings, enhancing vehicle handling and fuel efficiency in automotive and aerospace applications. Carbon sandwich panels deliver excellent impact resistance and thermal insulation through their multi-layer composition, improving safety and durability. The choice between these composites depends on specific performance requirements such as load-bearing capacity versus energy absorption.

Durability and Damage Tolerance

Carbon monocoque structures exhibit superior durability due to their seamless, single-layer construction that evenly distributes stress, reducing the risk of cracks or delamination. Carbon sandwich panels enhance damage tolerance by combining a lightweight core material, such as foam or honeycomb, with carbon fiber skins that absorb impacts and prevent catastrophic failure. The choice between monocoque and sandwich panels depends on specific durability requirements and the expected types of mechanical loads or damage in the application's environment.

Sustainability and Recycling of Carbon Composites

Carbon monocoque structures offer high strength-to-weight ratios but face challenges in sustainability due to difficulties in recycling composite materials. In contrast, carbon sandwich panels, which combine carbon fiber skins with recyclable core materials like aluminum or foam, provide enhanced recyclability and reduced environmental impact. Innovations in chemical recycling and thermoplastic resins are advancing the circular economy potential for both carbon monocoque and sandwich panel composites.

Choosing the Right Carbon Material for Your Project

Carbon monocoque structures offer superior strength-to-weight ratios due to their single-shell design, making them ideal for high-performance applications such as aerospace and automotive chassis. Carbon sandwich panels incorporate a lightweight core between two carbon fiber skins, providing enhanced stiffness and impact resistance while reducing overall weight, perfect for marine and architectural uses. Selecting between these materials depends on balancing structural requirements, weight constraints, and cost efficiency specific to your project's demands.

Carbon Monocoque vs Carbon Sandwich Panel Infographic

materialdif.com

materialdif.com